Production scheduling optimization method for beer saccharification process

A technology for production scheduling and optimization methods, applied in control/regulation systems, instruments, adaptive control, etc., can solve problems such as complex production scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

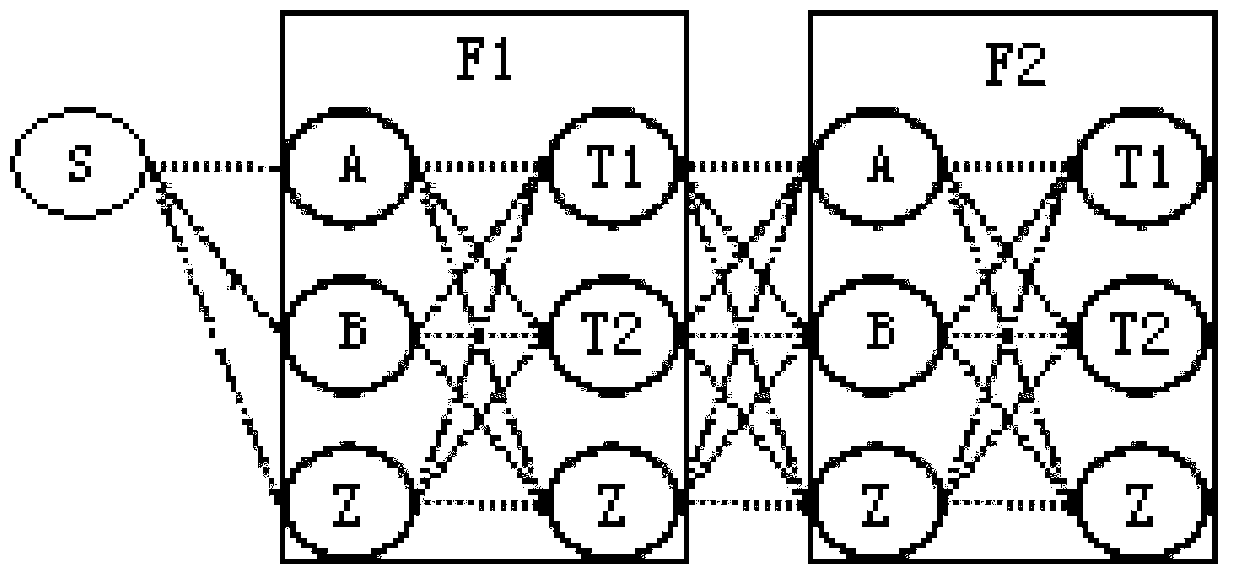

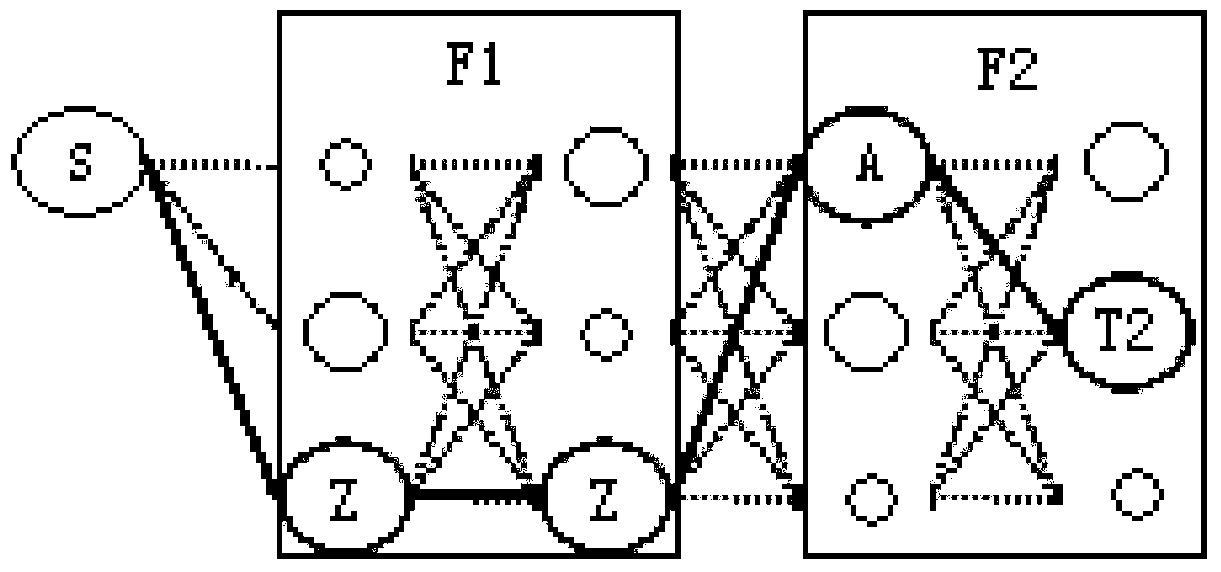

[0044] The present invention will be further described below in conjunction with accompanying drawing.

[0045] Concrete steps of the present invention are:

[0046] Step 1 needs to obtain data such as the number of beer saccharification equipment and fermentation tanks, beer varieties, length of scheduling time period, fermentation cycle, etc. These data can be obtained through beer manufacturers or statistics during the production process.

[0047] Step 2 establishes the comprehensive production scheduling estimation model through the production process parameters.

[0048] ①Material balance constraints

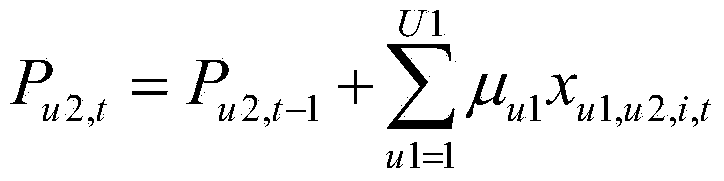

[0049] In each time interval t, according to the material balance, the storage amount in the fermenter should be the feeding amount of the saccharification equipment to the tank. It can be described as follows:

[0050] P u 2 , t = P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com