Optical fiber electronic distribution frame port detection method

An electronic distribution frame and port detection technology, which is applied in the field of optical fiber, can solve the problems of loose optical fiber plugging, falling off, positioning optical fiber plug, etc., and achieves the effects of good fixing effect, low detection error rate, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

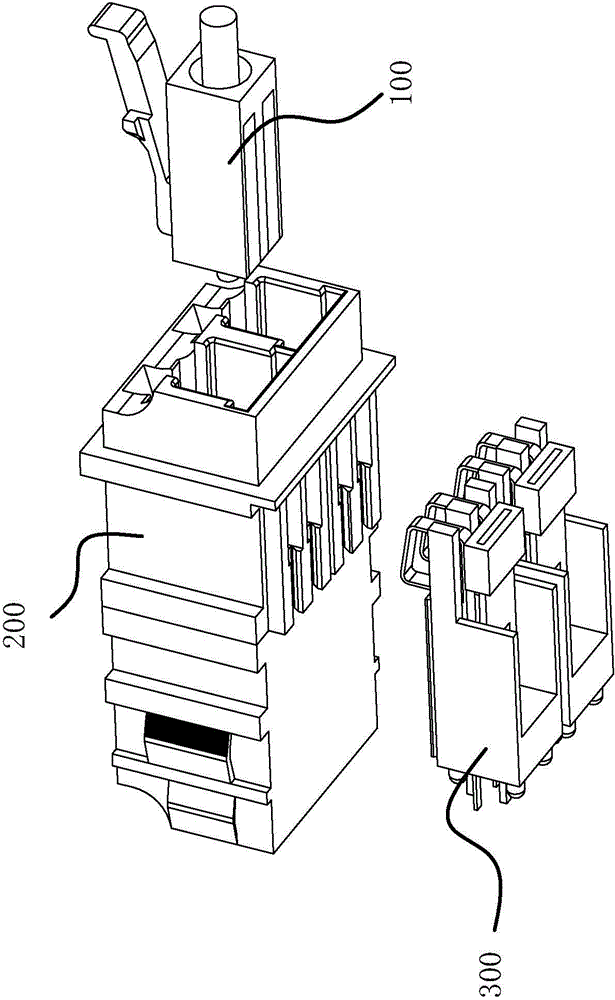

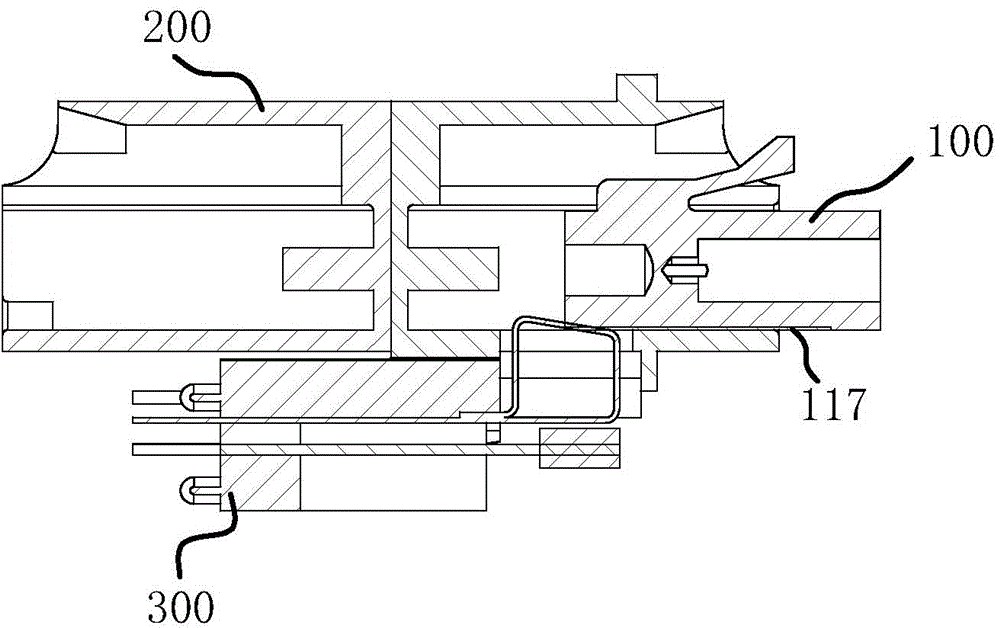

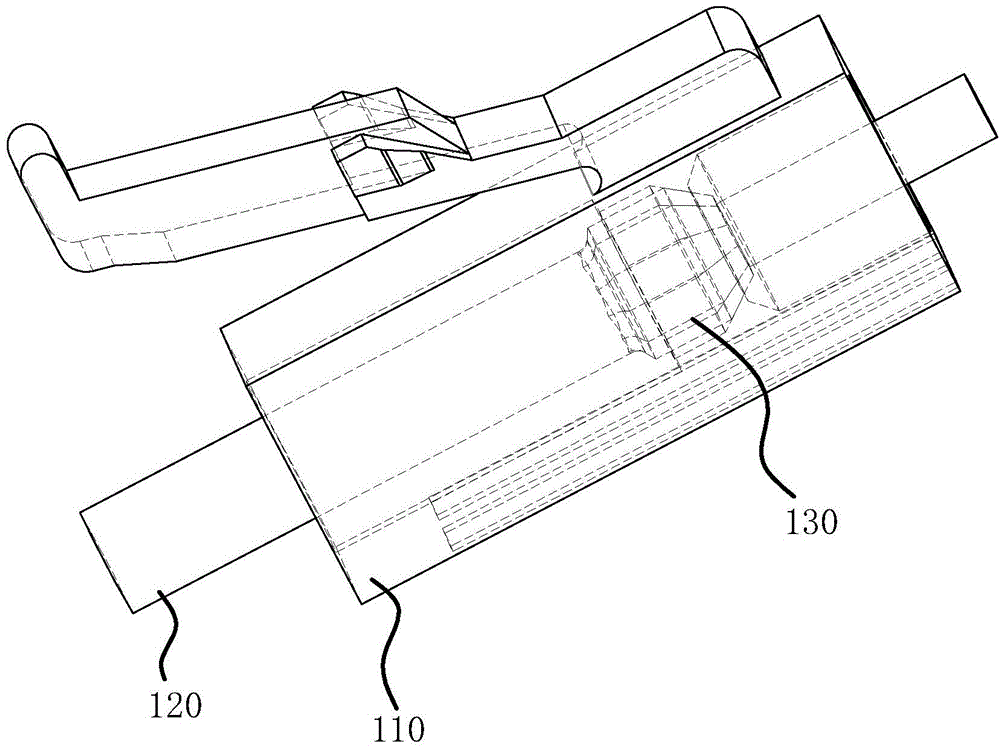

[0039] Please refer to Figure 1-Figure 13 , the optical fiber electronic distribution frame of the present invention includes an optical fiber plug 100 , an optical fiber socket 200 and a detection module 300 . The fiber optic plug 100 is plugged into the fiber optic socket 200. The fiber optic socket 200 includes a symmetrical front socket body 200' and a rear socket body 200", and the front socket body 200' and the rear socket body 200" are symmetrical with the partition plate 201 as a symmetrical plate. Setting, the middle part of the partition plate 201 is provided with an optical fiber accommodation cavity 202 which is connected to the front socket body 200' and the rear socket body 200 "and whose shape is adapted to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap