Testing method for mechanical property change of natural gas hydrate during decomposition

A test method, natural gas technology, applied in scientific instruments, analytical materials, measuring devices, etc., to achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

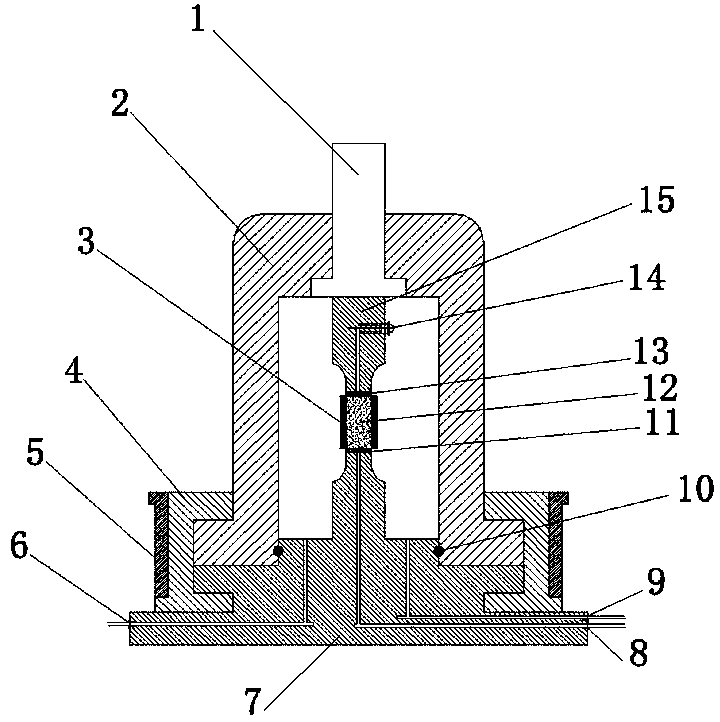

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0018] 1. A test method for natural gas hydrate mechanical properties: it is characterized in that: the steps are as follows:

[0019] 1) Making natural gas hydrate samples. The sample making method has been mentioned in detail in other patents of the same inventor. This method can make samples with specific void ratios according to the needs of experimenters;

[0020] 2) Install the sample and adjust the position of the sample. The installation of the sample includes installing the outer sleeve 3 of the magnetic conductor, installing the upper and lower percolation plates 11, 13, installing the upper pressure anvil 15, and accurately installing the above-mentioned combination on the base of 7. The entire installation and combination process must keep the sample 12, The center lines of the upper and lower seepage plates 11, 13, the upper pressure anvil 15 and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com