Optical fiber liquid level dynamic monitor

An optical fiber and gear transmission technology, applied in the field of optical fiber liquid level dynamic monitors, can solve the problems of poor electrical insulation, great influence on measurement accuracy, poor safety of flammable and explosive liquids, etc., and achieves less impact on the external environment and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

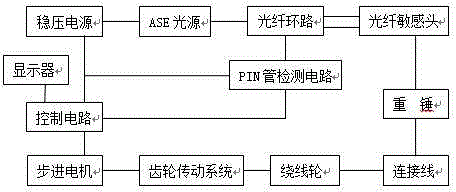

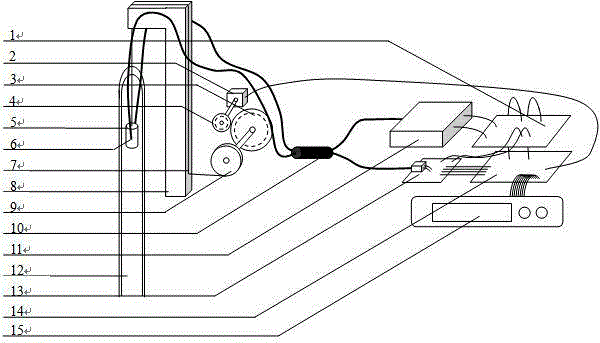

[0008] The specific implementation plan is as follows: figure 1 Is the structural block diagram of the patent of the present invention, figure 1 The working principle is: first power on the stabilized power supply, set the reference position of the liquid level through the control circuit board, the stabilized power supply drives the ASE light source to emit light, and reach the optical fiber sensor through the optical fiber loop, which is generated according to the position of the optical fiber sensor The reflected light of different intensity is transmitted to the PIN tube detection circuit through the optical fiber loop. The PIN tube detection circuit converts the light signal into an electrical signal and transmits it to the control circuit board. After the control circuit board processes the transmitted electrical signal, the control circuit board will The liquid level is displayed on the display, and the control circuit board outputs an electrical signal to control the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com