A binary vector nozzle capable of realizing s-bend occlusion function

A vector nozzle and functional technology, applied in the field of binary vector nozzles, can solve the problems of inability to achieve complete occlusion of high-temperature components, poor infrared stealth performance, unadjustable length of expansion section, etc., and achieve good infrared stealth performance and stealth. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

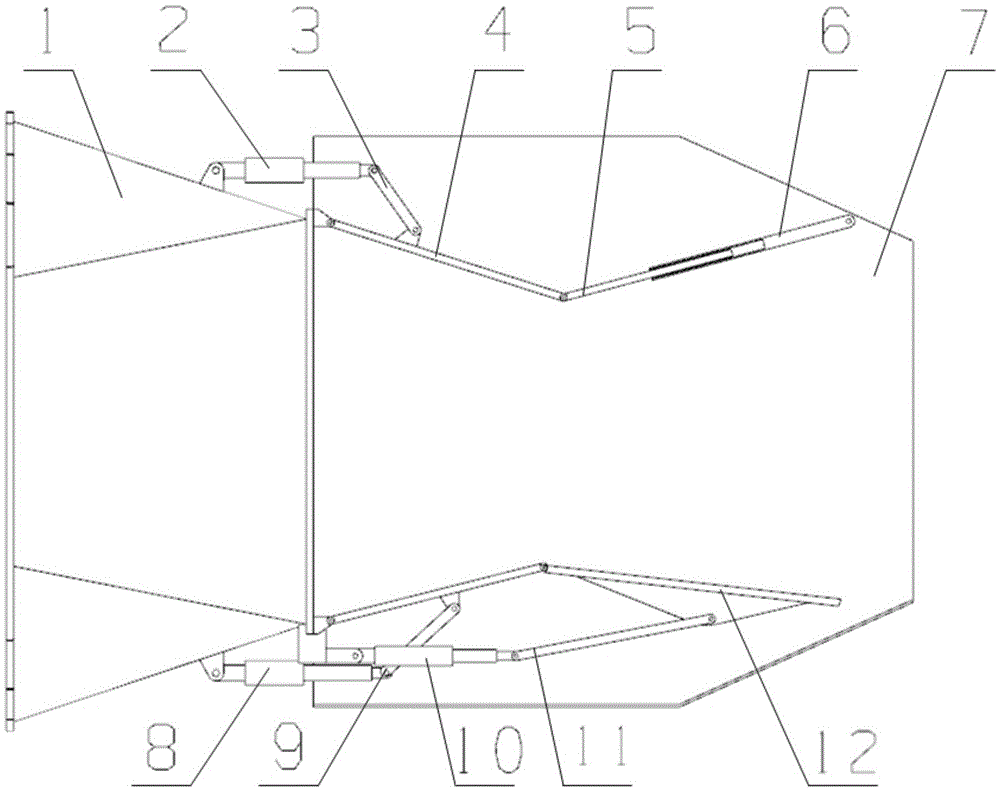

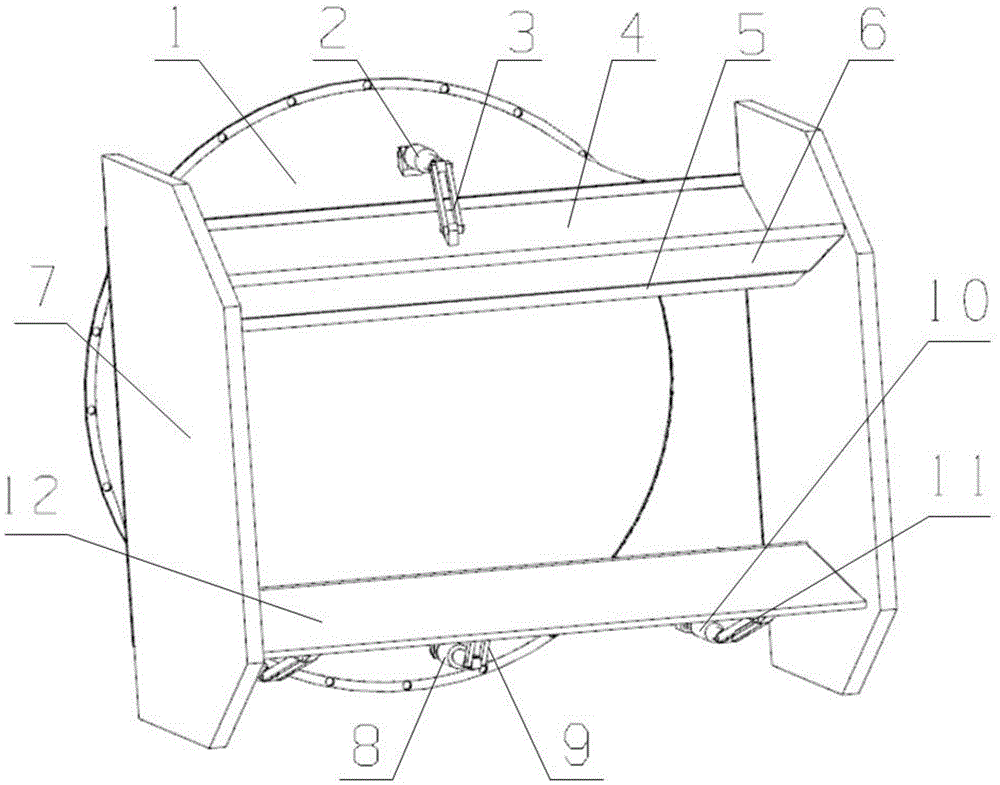

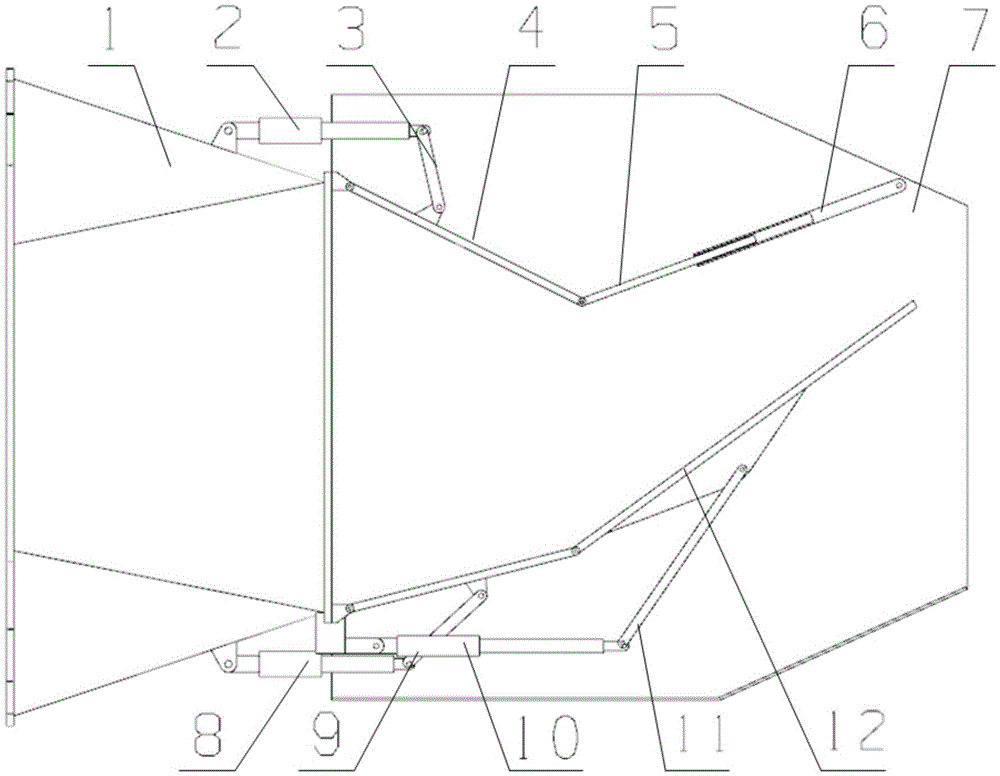

[0026] A binary vector nozzle capable of realizing the S-bend shielding function, mainly composed of a round-to-square cylinder 1, a throat adjustment mechanism, an expansion section adjustment mechanism, a side wall 7, and an outer cover 13, specifically:

[0027] The front end of the circular cylinder body 1 is connected with the engine as the supporting member of the whole nozzle.

[0028] The throat regulating mechanism is mainly composed of a first actuator 2 , a first pull rod 3 , a convergence adjustment plate 4 , a second actuator 8 and a second pull rod 9 . Wherein, the front end of the first actuator 2 is mechanically connected to the outer wall of the circular cylinder 1, and the other end is connected to the first pull rod 3 through the rotation pair; the first pull rod 3 is connected to the outer front section of the convergence adjustment plate 4 through the rotation pair connection; the convergence adjustment plate 4 is connected to the mounting edge of the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com