Garment dyeing equipment capable of reusing raffinate and its application method

A garment dyeing and equipment technology, which is applied in the processing of textile material equipment configuration, textile material processing, textile and papermaking, etc., can solve the problems of water resources, steam waste, and multiple sewage, and achieve the effect of reducing sewage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

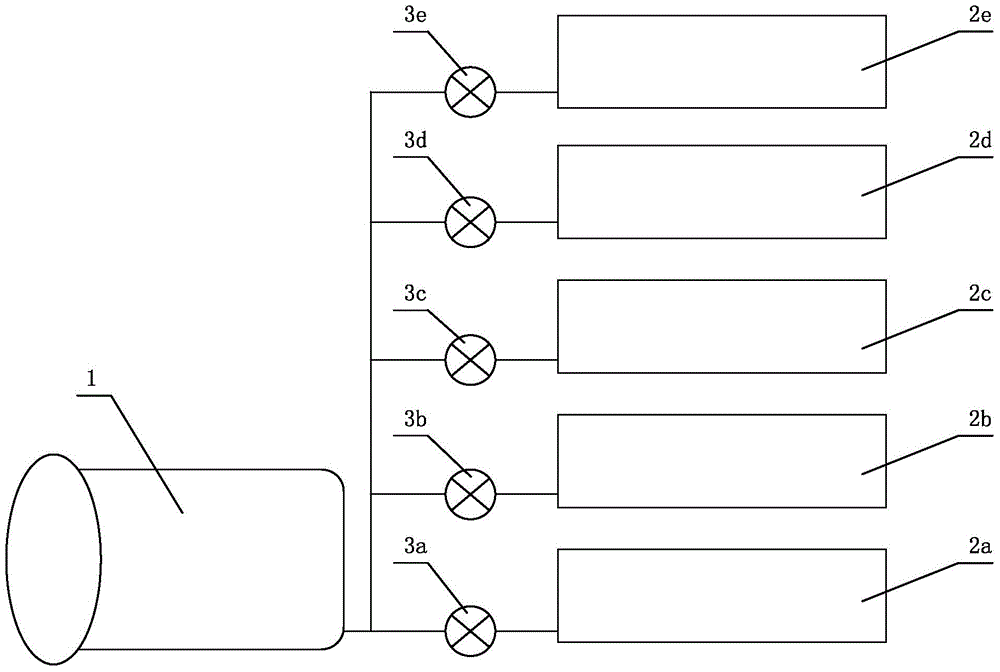

[0017] Such as figure 1 As shown, a garment dyeing device capable of reusing residual liquid in the present invention includes a dye vat 1 and a stainless steel container. There are one or several stainless steel containers in total, and the stainless steel container communicates with the dye vat 1 through a pipeline with a water pump.

[0018] The number of stainless steel containers is set according to the dyeing process and the actual need to reuse residual foot water, generally 3-5 are enough. In this embodiment, there are five stainless steel containers in total, namely: stainless steel container 2a, stainless steel container 2b, stainless steel container 2c, stainless steel container 2d, and stainless steel container 2e. The stainless steel container 2a communicates with the dye vat 1 through a pipeline with a water pump 3a, the stainless steel container 2b communicates with the dye vat 1 through a pipeline with a water pump 3b, the stainless steel container 2c communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com