Blowing-filling-sealing integrated machine

An all-in-one machine, blow-fill-seal technology, applied in bottling machines, liquid handling, liquid materials, etc., can solve problems such as low production efficiency, long intermittent time, increased manufacturing costs of mold sets and filling heads, and achieve high production efficiency Improvement, high reliability, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

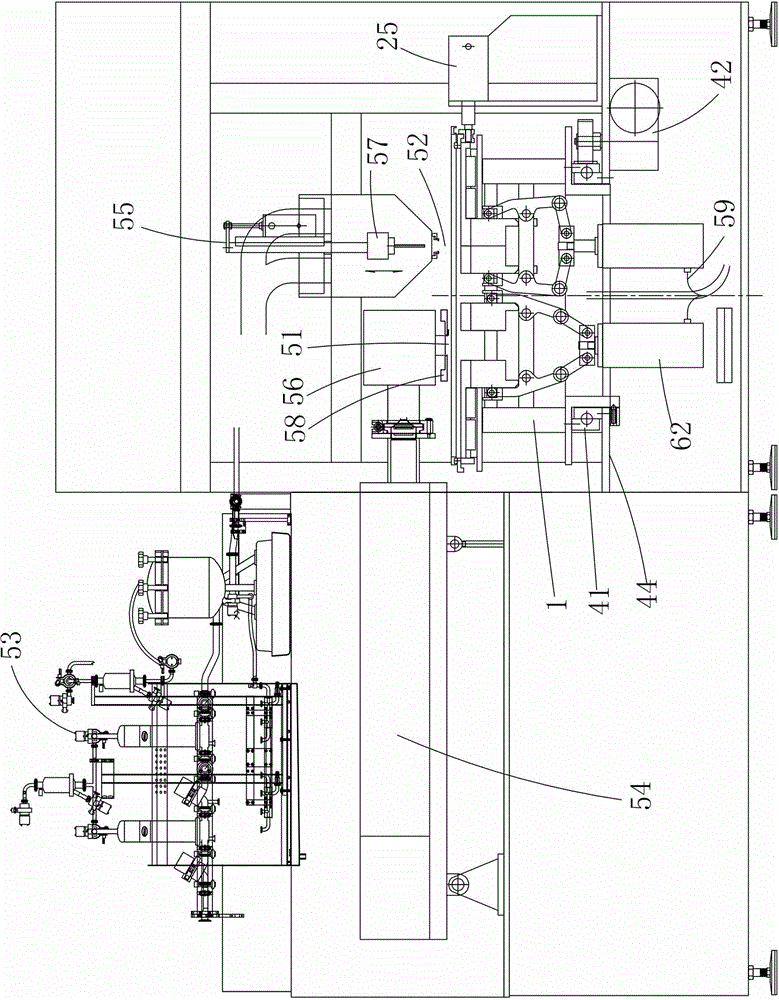

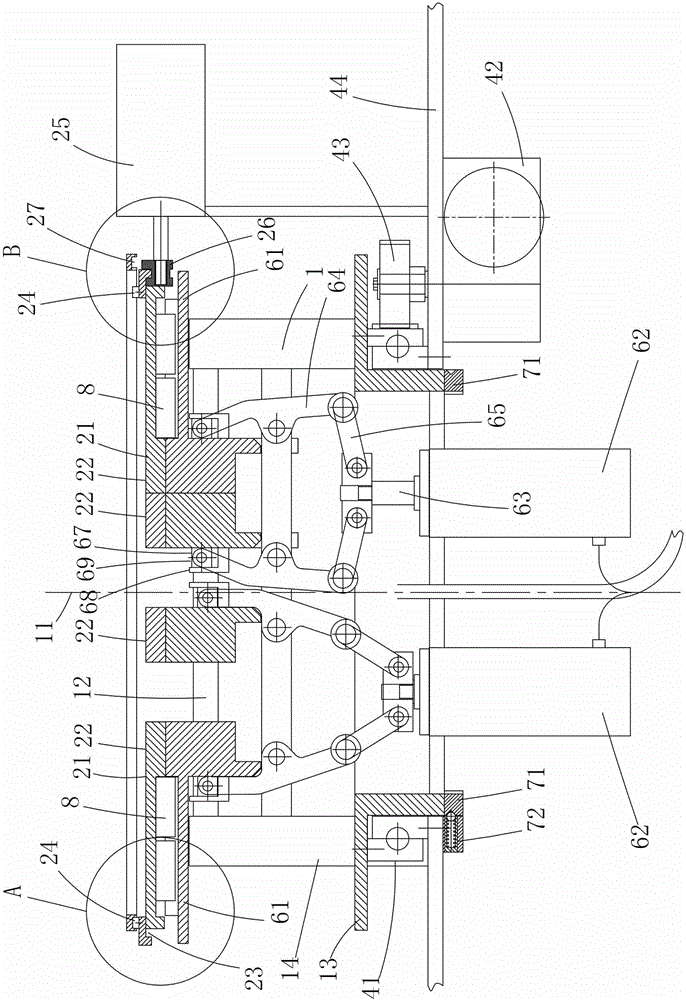

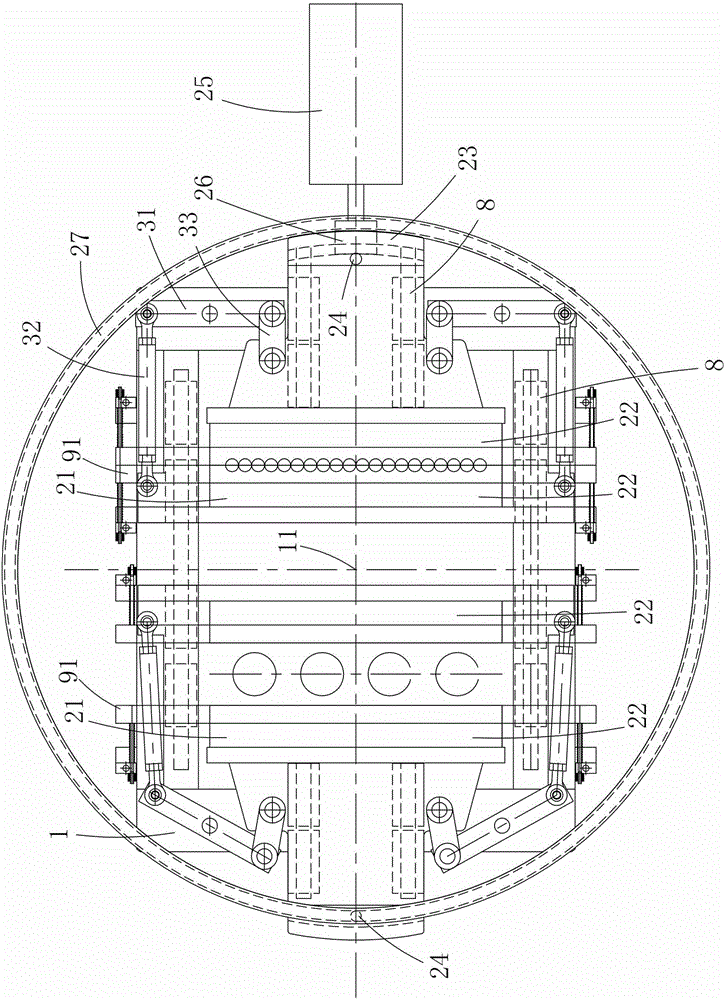

[0029] Such as figure 1 , figure 2 , image 3 As shown, the blow-fill-seal integrated machine of the present invention includes a feeding system (not shown in the figure), an electric control system (not shown in the figure), a liquid filtration system 53, a screw extrusion system 54 and a filling system 55. The all-in-one machine is equipped with a parison receiving station 51 and a filling and sealing station 52. The parison head device 56 of the screw extrusion system 54 is located at the parison receiving station 51, and the filling head device 57 of the filling system 55 is located at the filling and sealing station 52. The sealing station 52 and the parison receiving station 51 are also provided with a hot cutter device 58 for cutting off the tube blank. The blow-fill-seal all-in-one machine also includes a revolving seat 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com