A device and method for quickly dismantling, separating and assembling the middle transfer point of a scraper

A scraper and handover point technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and laborious maintenance, personnel injury, secondary damage to equipment, etc., to achieve wide application, save maintenance costs, improve The effect of maintenance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

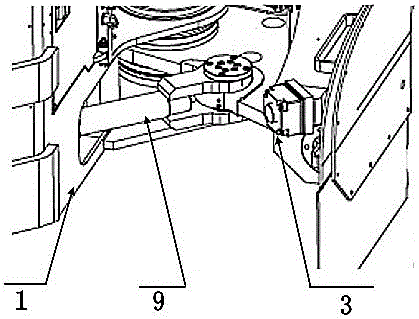

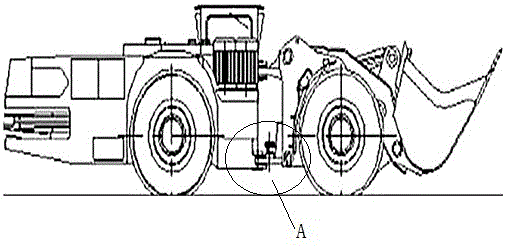

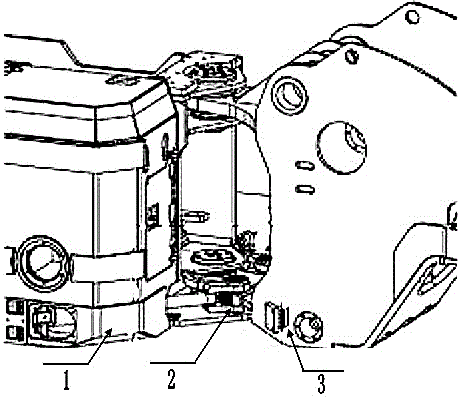

[0021] Embodiment: As shown in the figure, a device for quickly disassembling, separating and assembling the middle junction point of a scraper, including a hydraulic jack 10, a sleeper box 14, and a moving roller 16, and the middle of the sleeper box 14 is provided with a hydraulic The interlayer iron plate 13 of the jack 10, the side of the sleeper box 14 of the interlayer iron plate 13 is provided with a moving roller fixing hole 12, and the side of the sleeper box 14 above the interlayer iron plate 13 is provided with a hydraulic jack oil pipe joint hole 15 The side of the hydraulic jack 10 is provided with a hydraulic jack oil pipe joint 11 installed in the hydraulic jack oil pipe joint hole 15; the two sides of the mobile roller 16 are provided with a mobile roller fixed end installed in the mobile roller fixed hole 12 17: The sleeper box 14 is an iron sleeper box. During specific implementation, the hydraulic jack 10 is placed on the interlayer iron plate 13 in the iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com