Improved Continuous Mixing and Heat Removal Chemical Production Plant

A chemical production, static mixer technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as inconvenient maintenance, long distance between mixing head and tube-bundle static mixer, complex structure, etc., and achieve low by-products , the effect of strengthening the mass transfer process between gas/liquid substances and reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

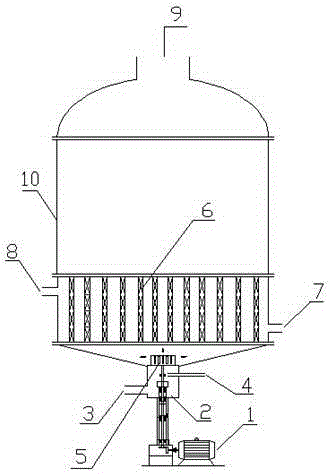

[0017] Embodiment 1, with reference to figure 1 , an improved continuous mixing heat removal chemical production device, including a tube bundle static mixer, a stirring head, and a motor, the motor 1 is directly connected to a stirring head 5 through a bevel gear, and the stirring head 5 is placed in a tube bundle static mixer The bottom of the tube bundle in 6 is placed vertically, the liquid / liquid or liquid / gas feeding chamber 2 is set under the stirring head 5, and the liquid / liquid or liquid / gas feeding chamber 2 has liquid feeding ports on both sides 3 and a gas feed port 4; the gas feed port 4 extends to the stirring shaft of the stirring head 5 to better disperse the air flow; the wall of the tube bundle static mixer 6 is provided with a cooling or heating inlet and outlet 7 , 8, the top of which has a discharge port 9.

[0018] The nominal diameter of a single tube in the tube-bundle static mixer 6 is not greater than 50mm, and any integer between 1-50mm can be sele...

Embodiment 2

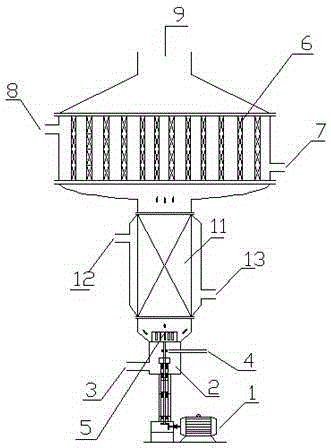

[0030] Embodiment 2, with reference to figure 2 , an improved continuous mixing heat removal chemical production device, including a tube bundle static mixer, a stirring head, and a motor, the motor 1 is directly connected to a stirring head 5 through a bevel gear, and the stirring head 5 is placed in a tube bundle static mixer The bottom of the tube bundle in 6 is placed vertically, the liquid / liquid or liquid / gas feeding chamber 2 is set under the stirring head 5, and the liquid / liquid or liquid / gas feeding chamber 2 has liquid feeding ports on both sides 3 and a gas feed port 4; the gas feed port 4 extends to the stirring shaft of the stirring head 5 to better disperse the air flow; the wall of the tube bundle static mixer 6 is provided with a cooling or heating inlet and outlet 7 , 8, the top of which has a discharge port 9. A single tube static mixer 11 is installed between the tube bundle static mixer 6 and the liquid / liquid or liquid / gas feed chamber 2 as a pre-reacti...

Embodiment 3

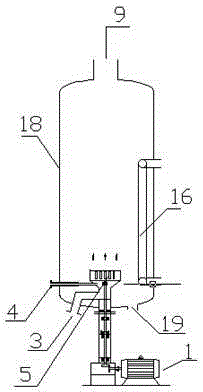

[0047] Embodiment 3 refers to image 3 , an improved continuous mixing heat removal chemical production device, including a tube bundle static mixer, a stirring head, and a motor, the motor 1 is directly connected to a stirring head 5 through a bevel gear, and the stirring head 5 is placed in a tube bundle static mixer The bottom of the tube bundle in 6 is placed vertically, the liquid / liquid or liquid / gas feeding chamber 2 is set under the stirring head 5, and the liquid / liquid or liquid / gas feeding chamber 2 has liquid feeding ports on both sides 3 and a gas feed port 4; the gas feed port 4 extends to the stirring shaft of the stirring head 5 to better disperse the air flow; the wall of the tube bundle static mixer 6 is provided with a cooling or heating inlet and outlet 7 , 8, the top of which has a discharge port 9. The upper end of the tube-bundle static mixer 6 and the upper end of the outlet 9 are equipped with a single-tube static mixer 11 as a supplementary reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com