Method for preparing compound seasoning with flavor of tomato braised beef brisket by combining vacuum frying technology and microcapsule embedding technology

A compound seasoning and vacuum frying technology, applied in the field of seasonings, can solve the problems of large loss of nutrients, insufficiency, low efficiency, etc., and achieve the effects of excellent taste, high production efficiency and rich nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

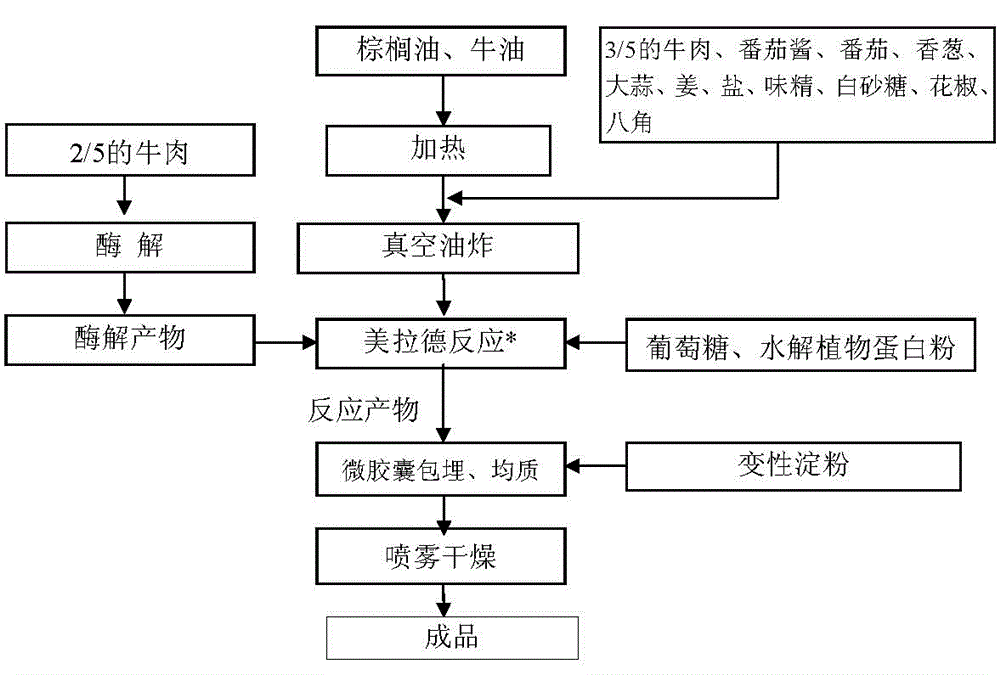

[0018] In concrete implementation, the present invention is realized by the following steps:

[0019] (1) Ingredients: It is composed of the following raw materials by weight percentage: 35% palm oil, 10% butter (refined), 15% tomato paste, 10% beef, 7.5% white sugar, 5% tomato, 5.5% edible salt %, shallot 4%, monosodium glutamate 3%, garlic 2%, ginger 2%, star anise 0.5% and pepper 0.5%, of which 3 / 5 of beef is used for vacuum frying, 2 / 5 of beef is used for enzymatic hydrolysis, pepper and star anise crushed into powder;

[0020] (2) Vacuum frying: According to the above ingredients, first add palm oil and butter to the vacuum frying equipment, preheat and heat to 110°C, add tomato sauce, 3 / 5 of beef, tomato, shallot, garlic , ginger, Chinese prickly ash and star anise are put into the vacuum frying equipment and then closed, and the vacuum pump is turned on to make the oil boil at 95°C-105°C. The time is 35-45 minutes. When the oil is boiling, the material can effectively...

Embodiment 2

[0024] The present invention can also be realized by the following steps in concrete implementation:

[0025] (1) Ingredients: It is composed of the following raw materials by weight: 35kg of palm oil, 10kg of butter (refined), 15kg of tomato sauce, 10kg of beef, 7.5kg of white sugar, 5kg of tomato, 5.5kg of edible salt, 4kg of shallot, 3kg of monosodium glutamate, 2kg of garlic, 2kg of ginger, 0.5kg of star anise and 0.5kg of Chinese prickly ash, of which 6kg of beef is used for vacuum frying, 4kg of beef is used for enzymatic hydrolysis, and the Chinese prickly ash and star anise are crushed into powder;

[0026] (2) Vacuum frying: According to the above ingredients, first add palm oil and butter to the vacuum frying equipment, preheat and heat to 110°C, then add tomato sauce, 6kg beef and tomatoes, shallots, garlic, ginger, Prickly ash and star anise are put into the vacuum frying equipment and closed, and the vacuum pump is turned on to make the oil boil at 95°C-105°C. The...

Embodiment 3

[0030] In specific implementation, the present invention can also be realized by the following steps:

[0031] (1) Ingredients: It is composed of the following raw materials by weight: 140kg of palm oil, 40kg of butter (refined), 60kg of tomato paste, 40kg of beef, 30kg of white sugar, 20kg of tomato, 22kg of edible salt, 16kg of chives, and 12kg of monosodium glutamate , 8kg of garlic, 8kg of ginger, 2kg of star anise and 2kg of Chinese prickly ash, among which 24kg of beef is used for vacuum frying, 16kg of beef is used for enzymatic hydrolysis, and Chinese prickly ash and star anise are crushed into powder;

[0032] (2) Vacuum frying: According to the above ingredients, first add palm oil and butter to the vacuum frying equipment, preheat and heat to 110°C, then add tomato sauce, 24kg beef and tomatoes, shallots, garlic, ginger, Prickly ash and star anise are put into the vacuum frying equipment and closed, and the vacuum pump is turned on to make the oil boil at 95°C-105°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com