A dryland small particle seed full film covering hole planter

A technology of full film coverage and small particles, applied in the field of seeders, can solve the problems of difficult control of sowing depth, uneven seedling emergence, low seed germination rate, etc. The effect of seedling emergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

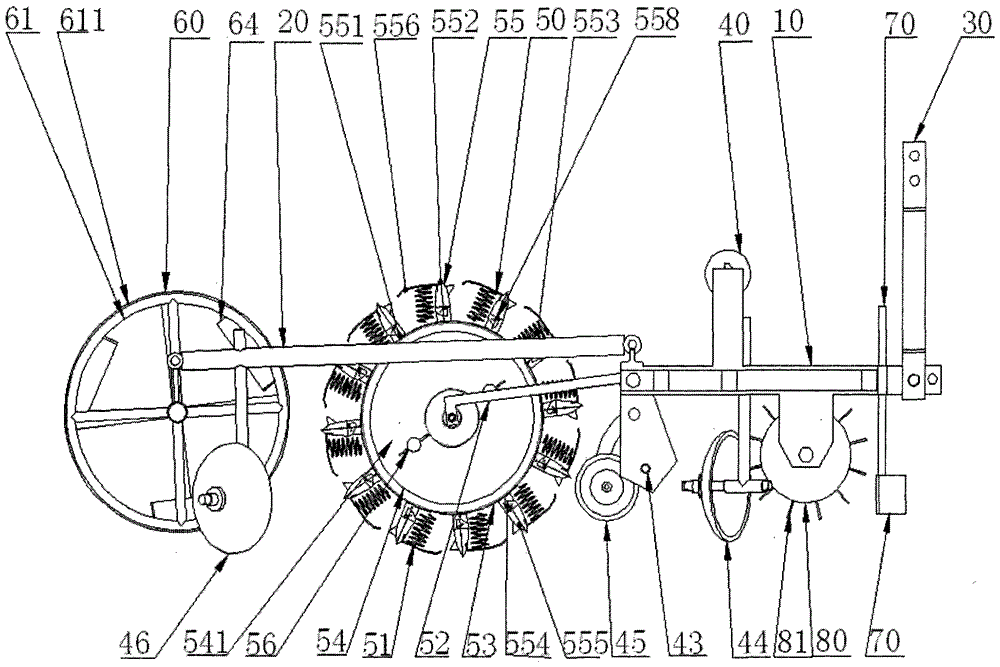

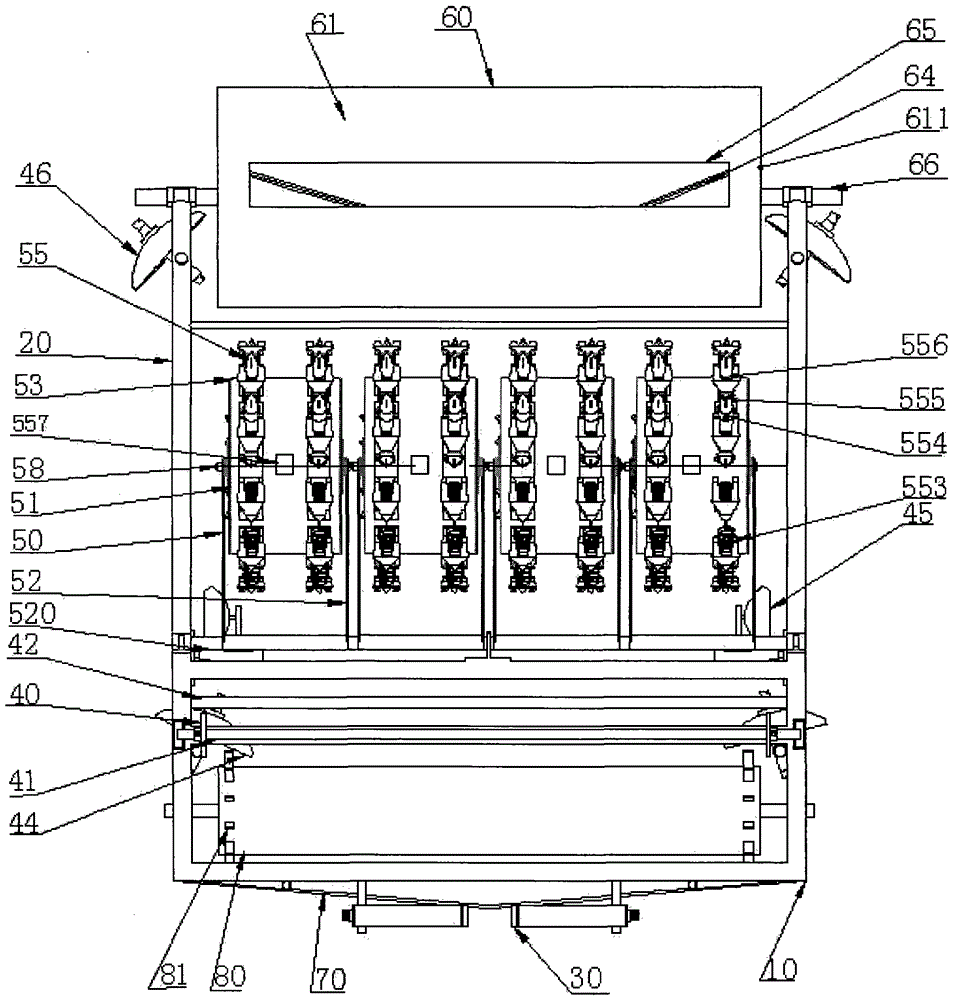

[0025] Example 1, see Figure 1-7 , a dryland small particle seed full-film covering hole planter, including a front frame 10, a rear frame 20, a suspension device 30, a film laying assembly 40, a hole planter assembly 50 and a soil covering assembly 60; the suspension device 30 Below is provided with bulldozing board 70; Front frame 10 is equipped with suppressing roller 80, film laying assembly 40 and seeder assembly 50; 43. The flat film wheel 45 and the film opener 44 are composed; the hole seeder assembly 50 is mounted on the rear of the front frame 10 through the hole seeder draw bar 520; the rear frame 20 is equipped with a soil covering assembly 60 and a soil scraping and film pressing device 46.

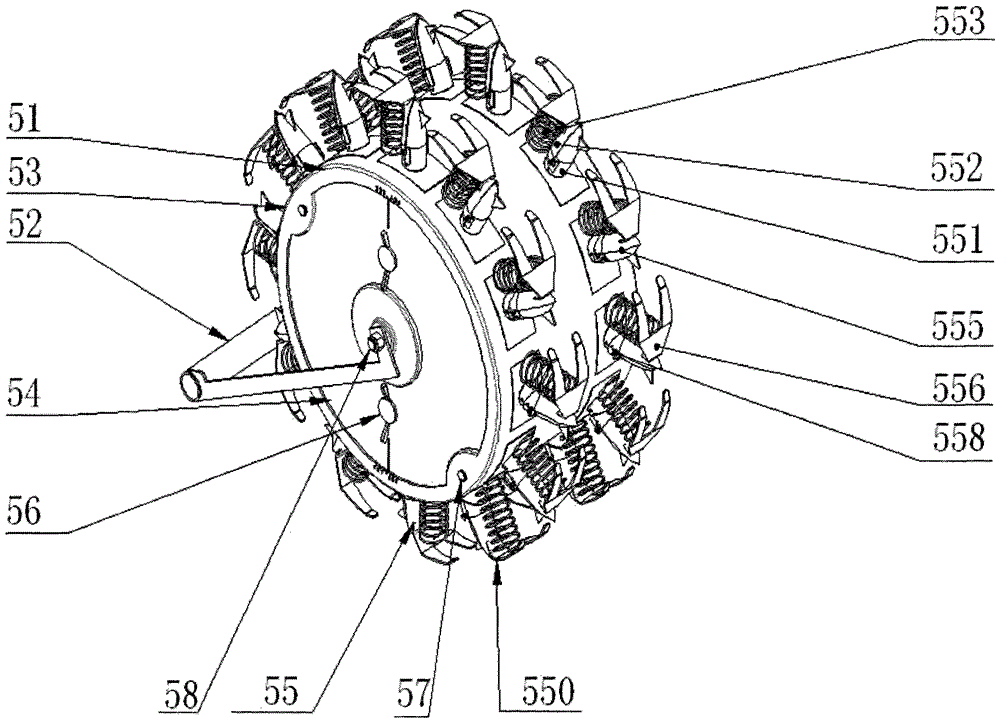

[0026] The hole planter assembly 50 includes one or more hole planters 51, each hole planter 51 has a pair of hole planter traction frames 52 connected to the outer cylinder 53 through a hole planter shaft 58, a pair of inner and outer cylinder lock pins 57; The gap betwee...

Embodiment 2

[0030]Embodiment 2 is the same as Embodiment 1, except that the hole seeder 51 is different. When sowing small particles of seeds in the barren wasteland and the forage field, adjust the adjustment knob 56 with the scale 542 on the inner drum side wall 541 to 2°, corresponding to the scale 1 marked on the side walls at both ends of the outer drum 53, the seed sowing rate of 2.5-3kg / mu of small particle seeds that can meet the agronomy of the barren wasteland field can be obtained.

Embodiment 3

[0031] Embodiment 3 is the same as Embodiment 1, but the difference is that the hole sower 51, when planting small particles of seeds in the forage grass field, adjust the adjustment knob 56 with scale on the inner drum side wall 54 to 4 ° , corresponding to the scale 2 marked on the side walls at both ends of the outer cylinder 53, the sowing rate of small particle seeds that can meet the agronomy of the forage grass field is 1.5-2kg / mu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com