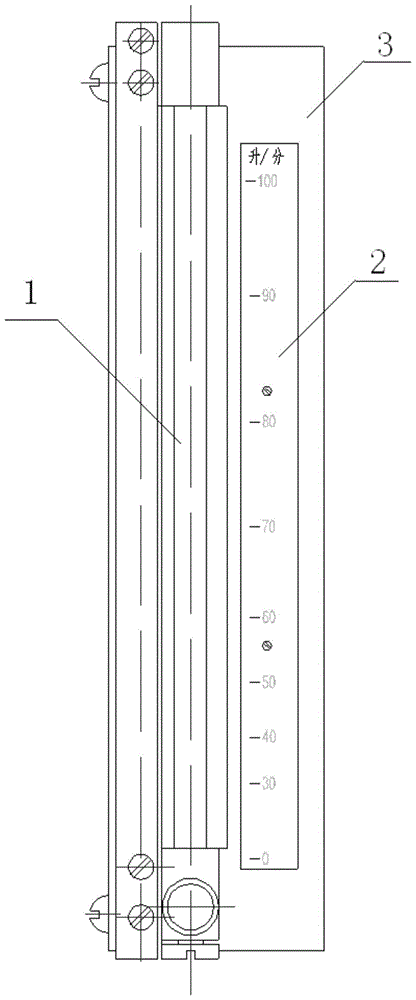

Rotary Scale for Gas Orifice Flow Meters

A gas hole and flowmeter technology, applied in the volume/mass flow generated by mechanical effects, detecting fluid flow by measuring pressure difference, volume indication and recording equipment, etc., can solve the problem of increased measurement error, increased preparation time, and measurement efficiency Drop and other problems, to achieve the effect of reducing measurement error, improving measurement efficiency, and facilitating conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

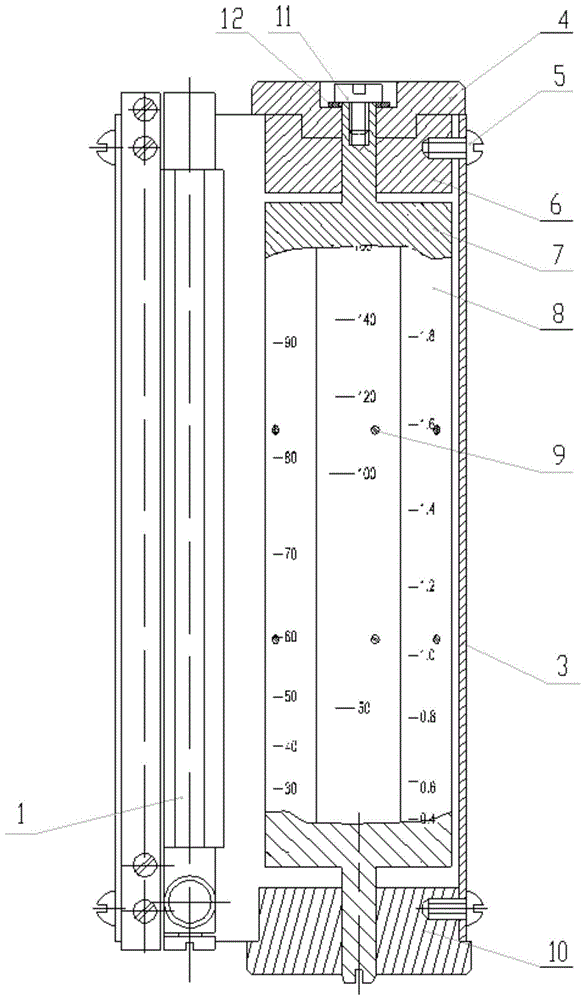

[0008] The present invention will be described in further detail below. see figure 2 , a rotary scale for gas orifice flowmeters, including a connecting pipe assembly 1 and a mounting bracket 3, the connecting pipe assembly 1 is fixed on the mounting bracket 3 by screws; it is characterized in that: there is a rotating scale fixed on the mounting bracket 3 , it consists of handle 4, rotating scale fixing screw 5, upper positioning sleeve 6, rotating base 7, scale 8, scale fixing screw 9, lower positioning sleeve 10, handle fixing screw 11 and washer 12; upper positioning sleeve 6 is a circle Ring, the upper positioning sleeve 6 is fixed on the upper part of the mounting bracket 3, near the upper end of the connecting pipe assembly 1 by rotating the scale fixing screw 5, the axis of the upper positioning sleeve 6 is kept vertical and parallel to the axis of the display tube in the connecting pipe assembly 1, The lower positioning sleeve 10 is also a ring, and the lower positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com