Double-end tuning fork three-dimensional resonance triggering probe system and true three-dimensional measurement method thereof

A double-ended tuning fork and three-dimensional technology, applied in the field of micro-nano probes, achieves high quality factor, guaranteed symmetry, and high trigger positioning resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

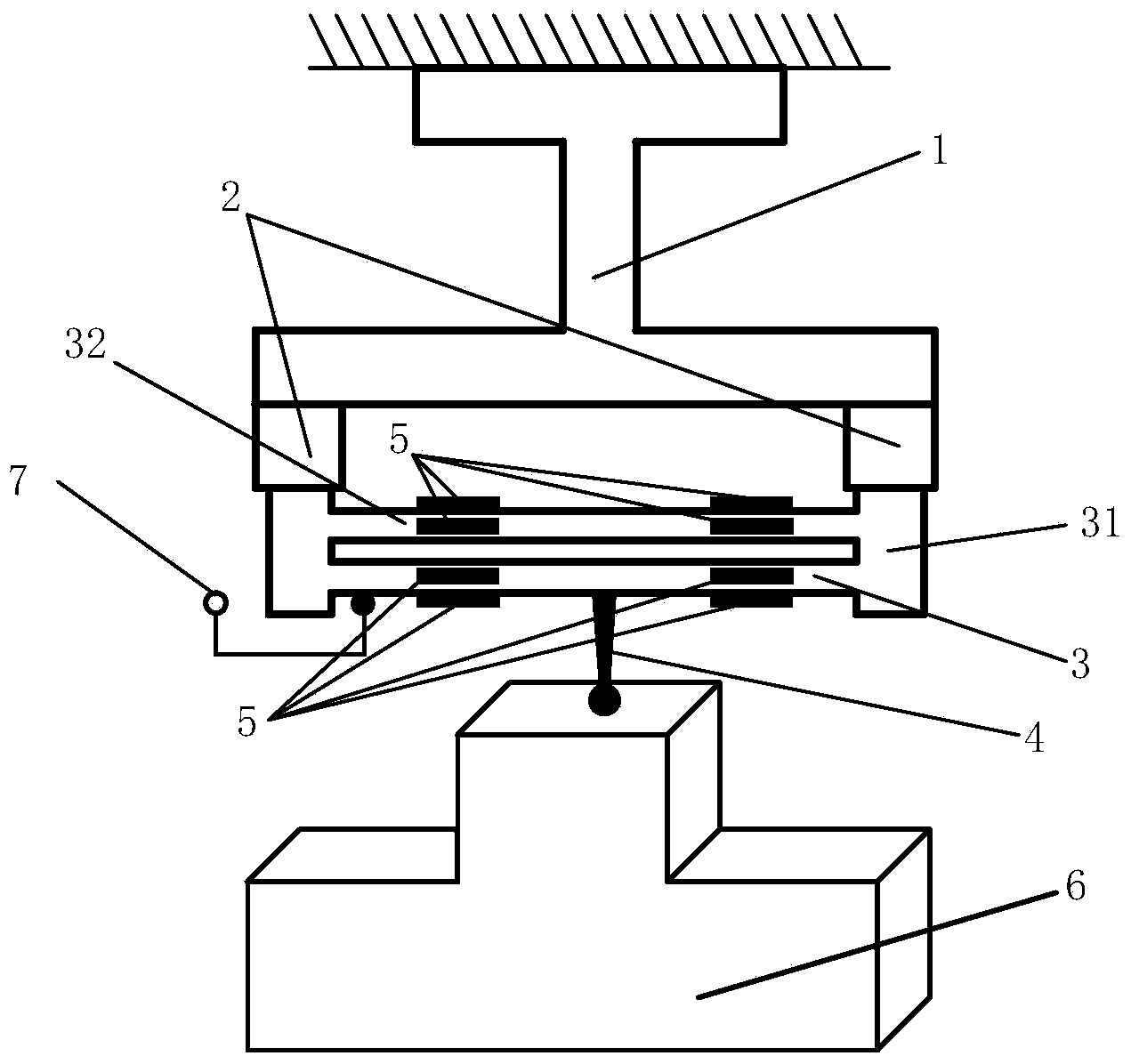

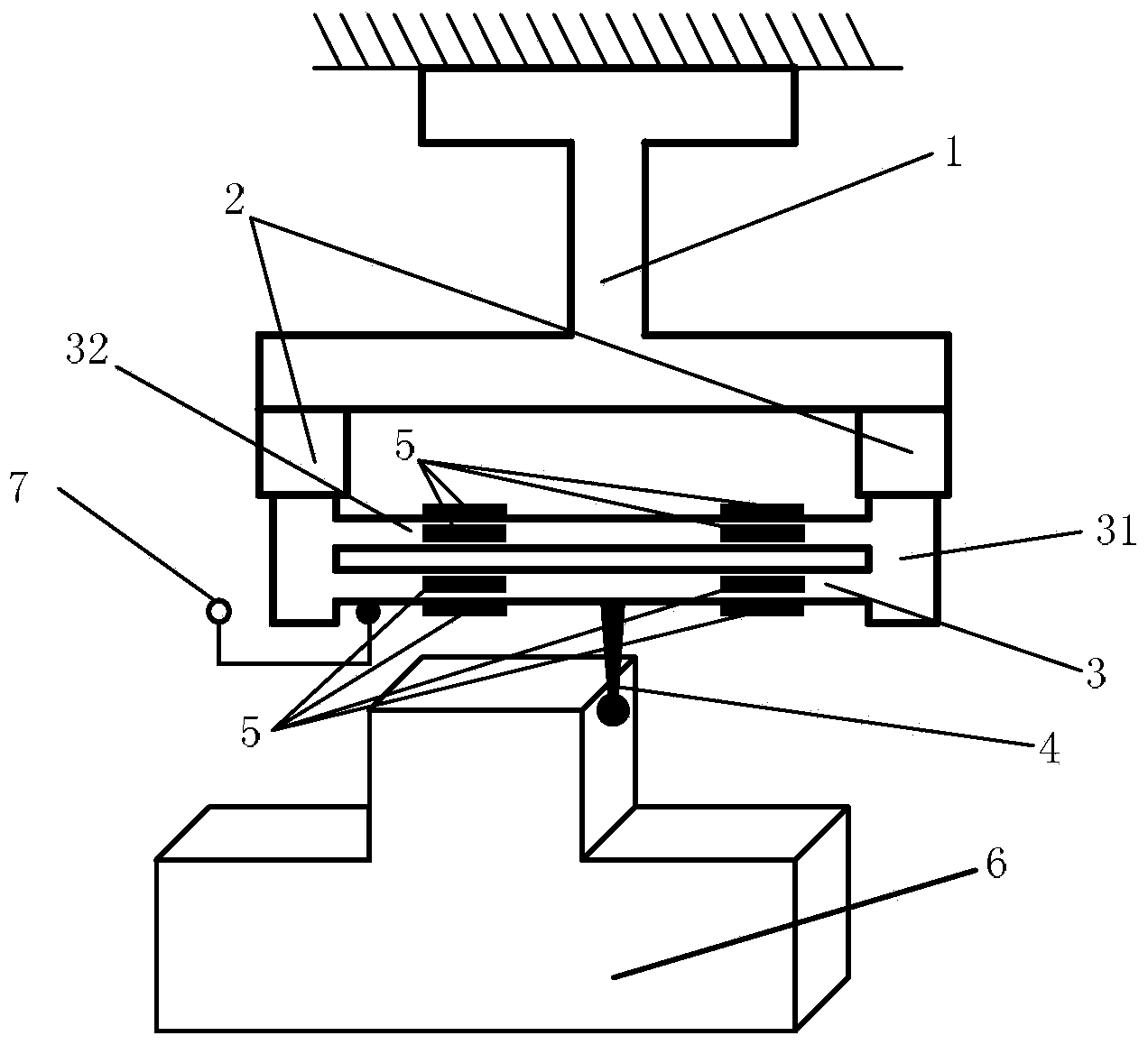

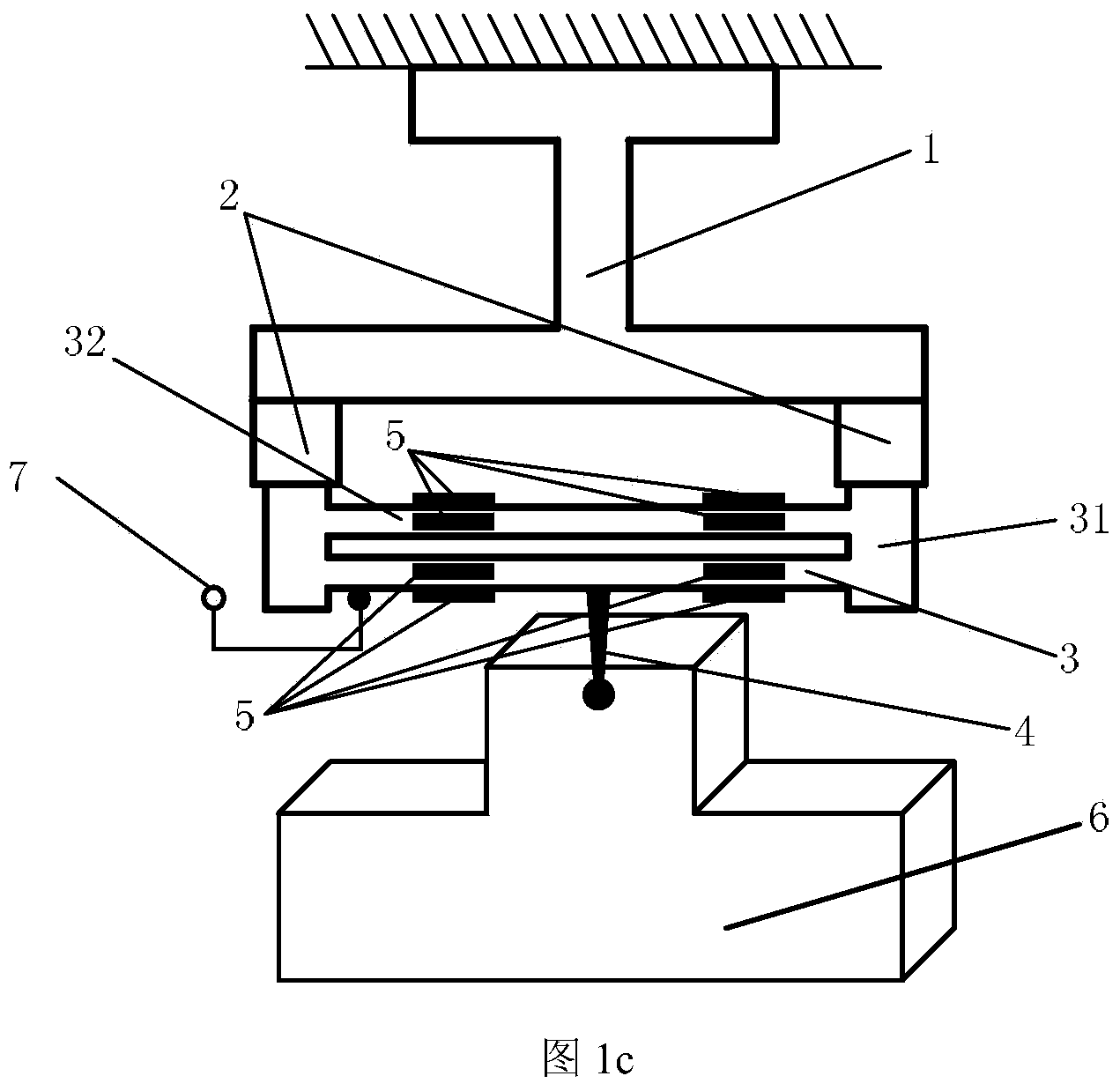

[0032] Such as figure 1 As shown, the double-ended tuning fork three-dimensional resonance trigger probe system includes a support frame 1, and the bottom frame surface of the support frame 1 is connected with two symmetrical adapters 2 at the same position, and also includes a double-ended tuning fork 3 and a double-ended tuning fork 3 It consists of two fork ends 31 and a pair of fork arms connecting the two fork ends 31. The two fork ends 31 of the double-ended tuning fork 3 are connected to the bottom surface of the adapter 2 in one-to-one correspondence. The two fork arms 32 of the fork arm pair are respectively Parallel to the bottom frame surface of the support frame 1 and arranged in parallel vertically, an integrated optical fiber micro-probe 4 is fixed on the middle bottom surface of the fork arm located below the center of the fork arm.

[0033] Electrodes 5 are arranged on the pair of fork arms of the double-ended tuning fork 1 , and the double-ended tuning fork 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com