Window with hinge assemblies capable of being hidden

A hinge and assembly technology, which is applied in the field of windows that can be hidden by hinge assemblies, can solve the problems of reduced load-bearing capacity, the thickness of load-bearing parts cannot be too thick, and the scope of use of hinge assemblies is limited, so as to improve the load-bearing capacity and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

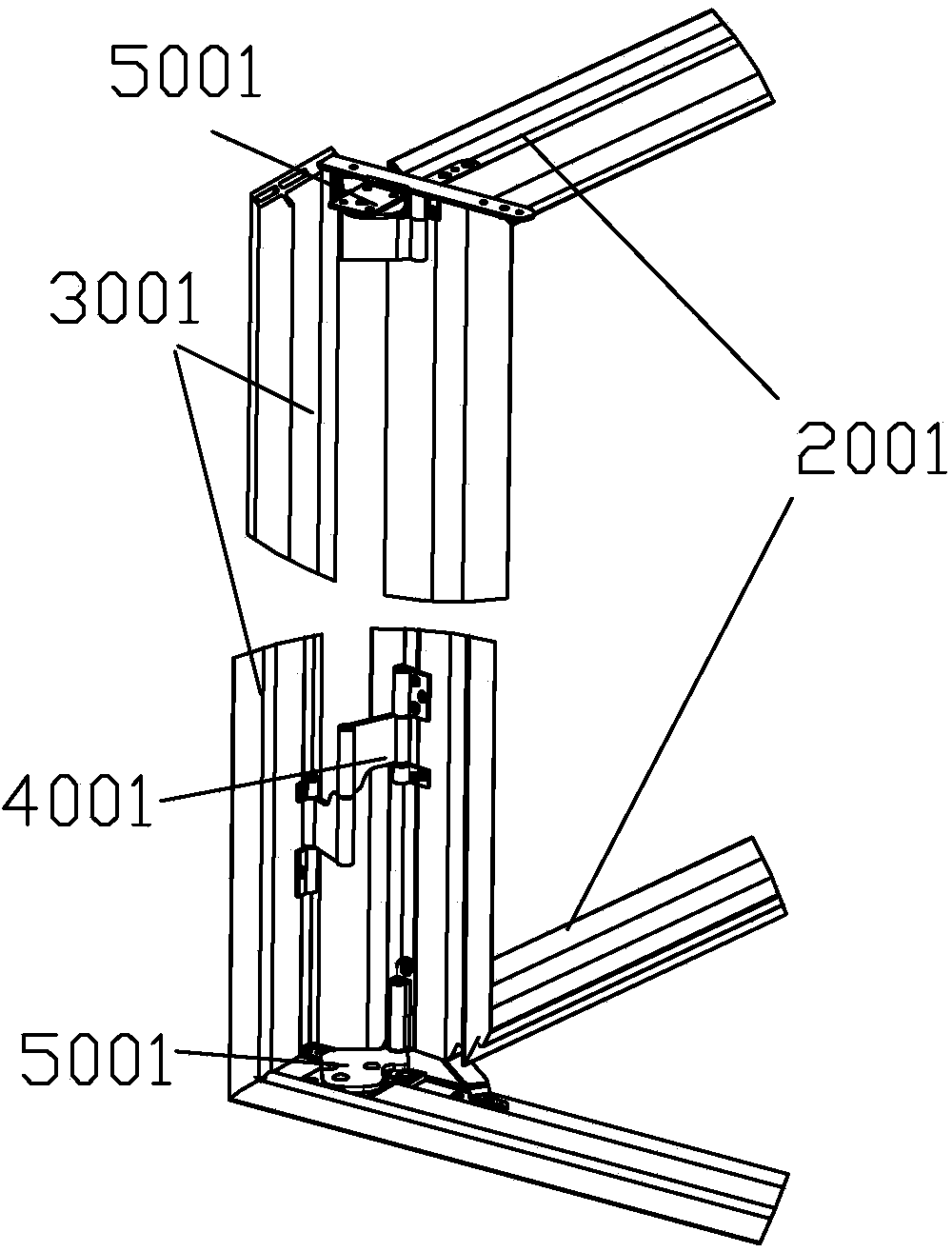

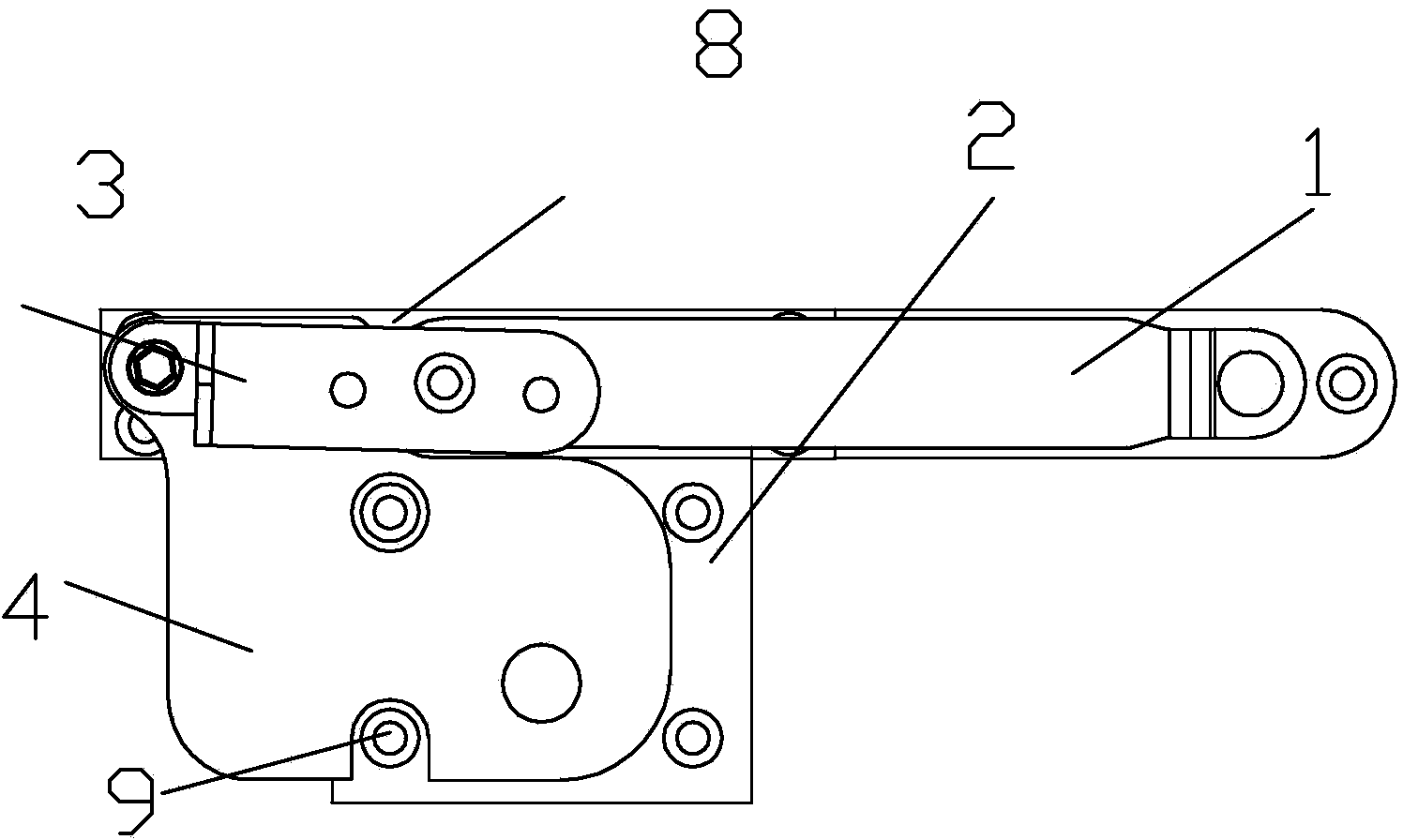

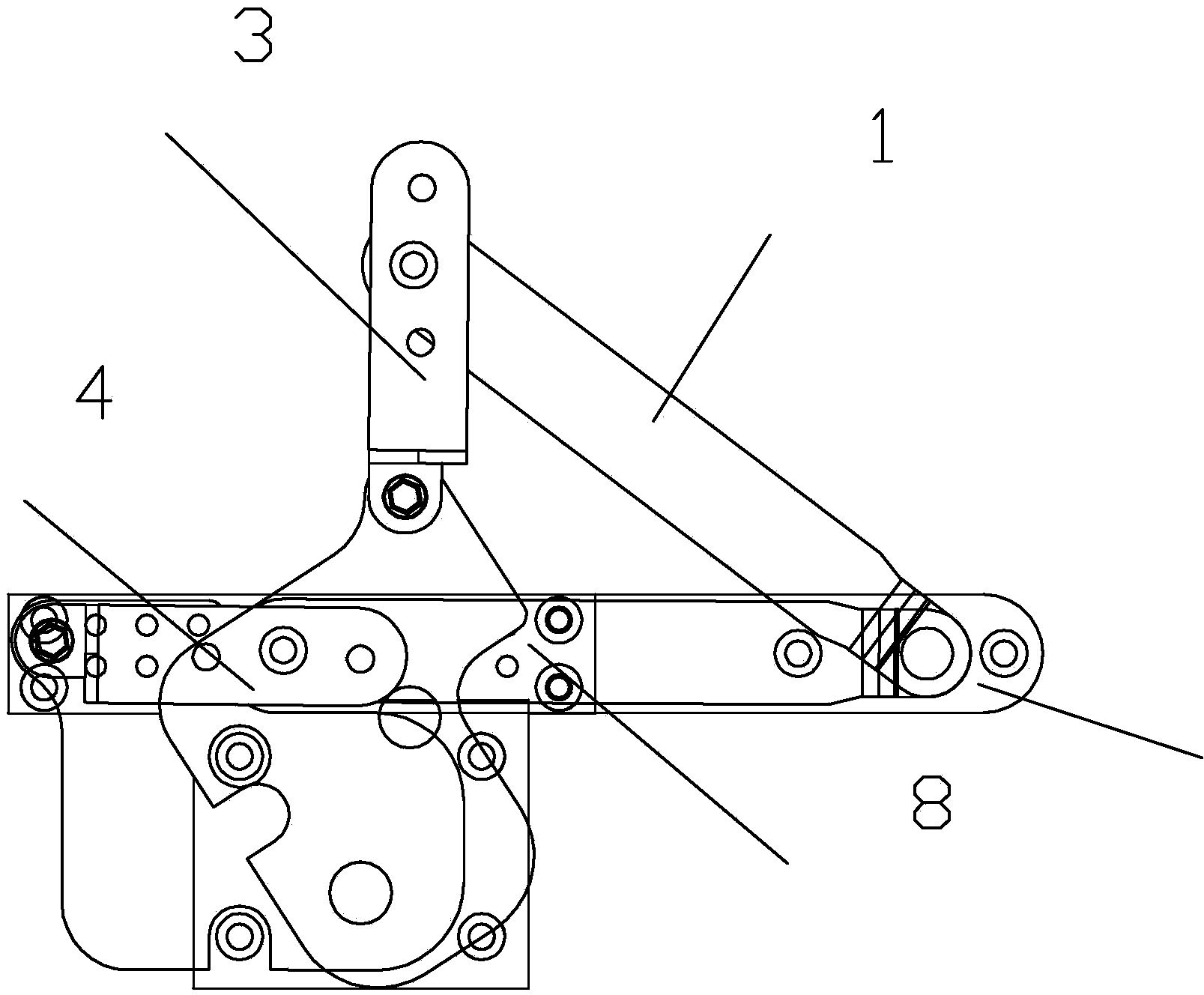

[0013] refer to figure 1 , figure 2 , image 3 , Figure 4 Shown: design a kind of window that hinge assembly can be concealed, be provided with fixed window frame 3001 and adopt upper and lower hinge assembly 5001 to connect with fixed window frame 3001 movable window 2001, upper and lower hinge assembly 5001 is provided with A four-bar linkage mechanism consisting of a connecting rod 3 fixed to the window sash, a fixed rod 2 fixed to the window frame, a load-bearing connecting rod 4, and a motion control rod 1. The sash fixing rod 3 is in an L-shaped structure. The back is integrally formed with a pin hole 302, and the window frame fixing rod 2 is composed of a square block 201 and an integrally formed fixing bar 203. Hinged, the other end of which is hinged to the middle of the horizontal side of the sash link 3, the load-bearing link 4 is a square structure, the rear side of the load-bearing link 4 is connected to the square block 201 in the window frame fixing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com