Large-span telescopic universal tower head fixture

A telescopic, large-span technology, applied in the direction of overhead lines/cable equipment, etc., can solve the hidden dangers of operation safety and operation safety, the unavailability of seat plates and lead screws, and the unavailability of insulating pull plates, etc., to improve the operability. Sexual range, light weight, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

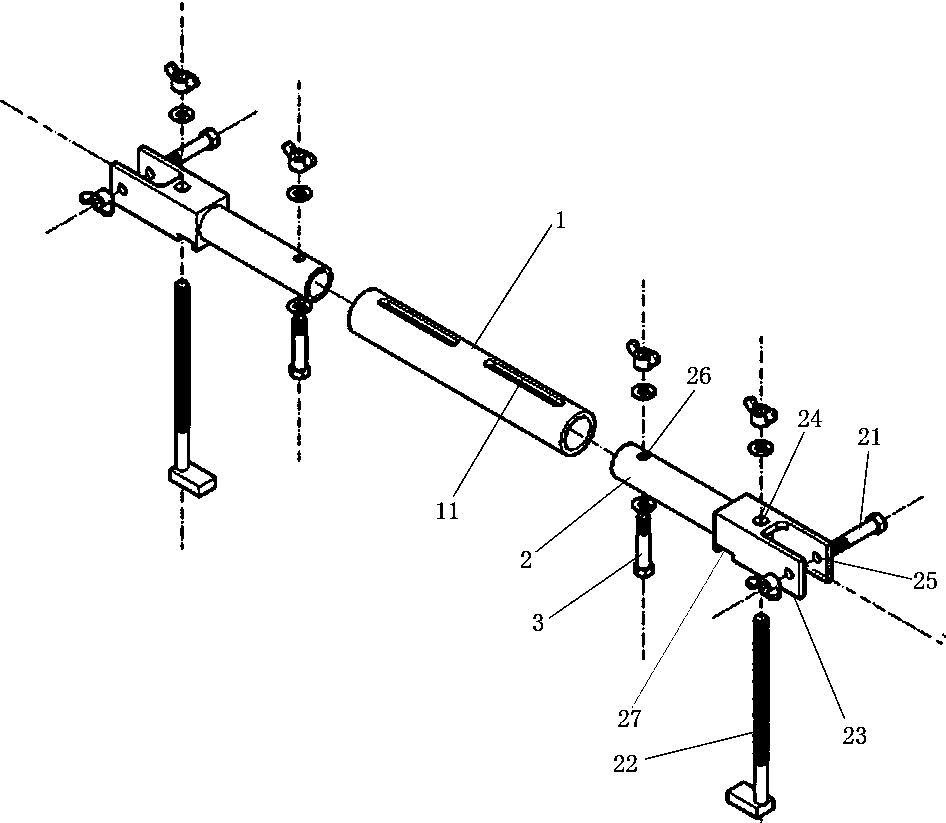

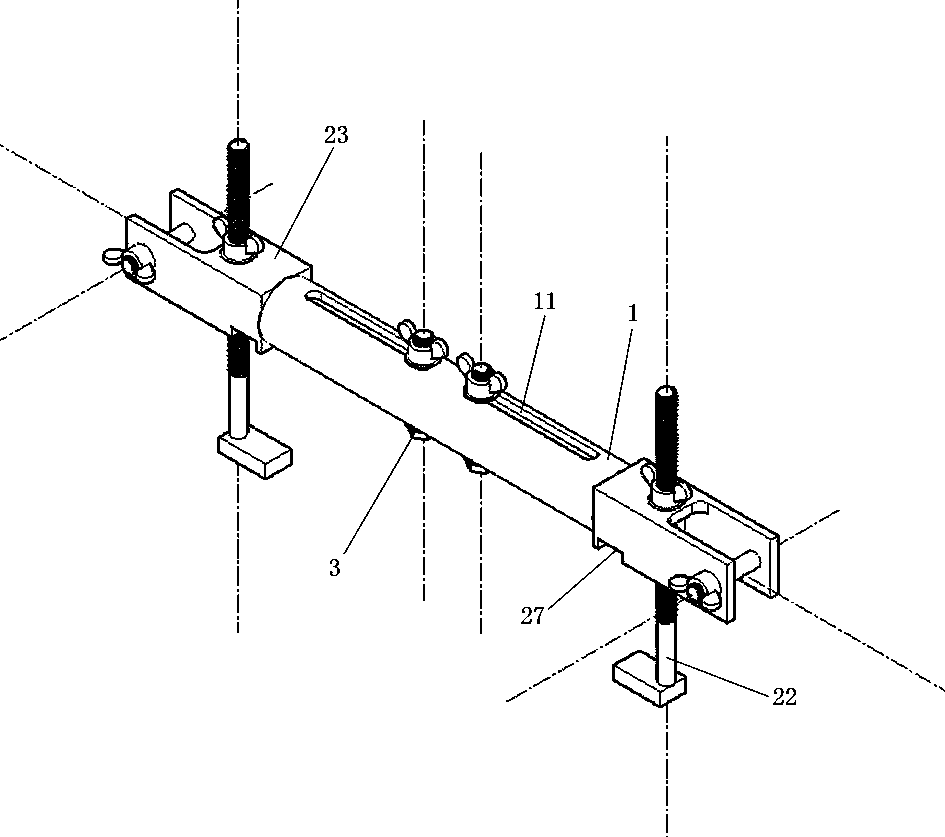

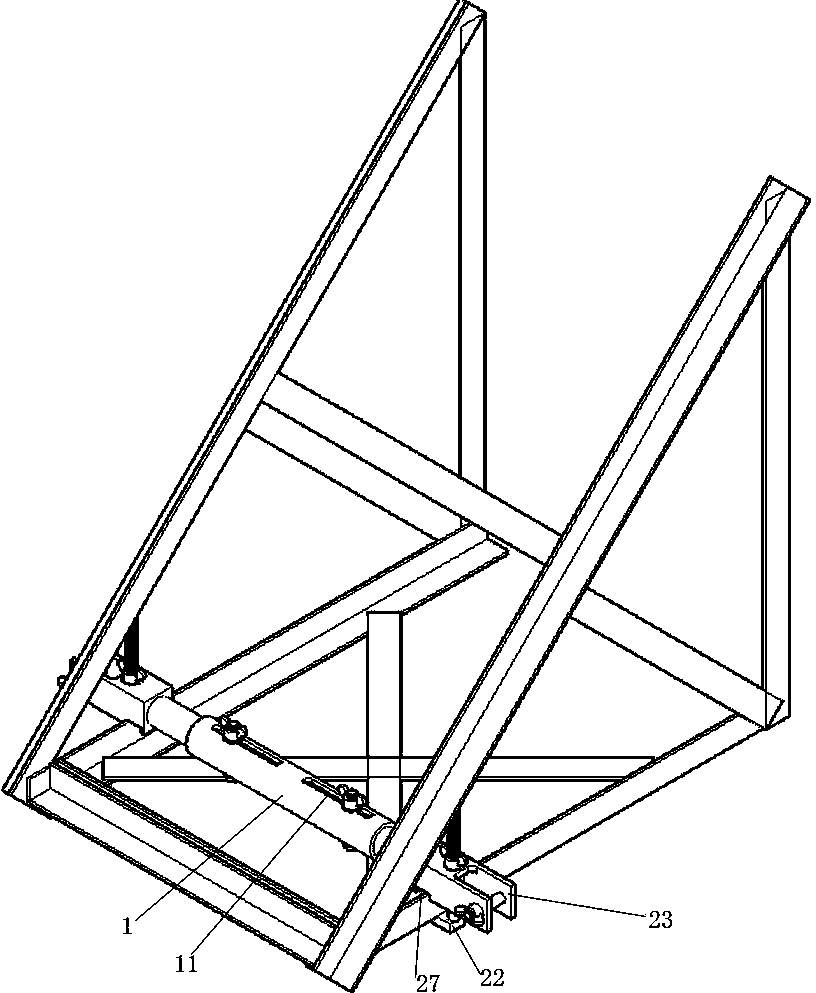

[0016] Such as figure 1 , 2 As shown, the large-span telescopic universal tower head fixture of the present invention includes an intermediate beam 1, a cover beam 2, a hook bolt 22 and a pulley line hanging rod 21, and there are two cover beams 2, which are symmetrically and flexibly connected to the middle beam. On both sides, the tail end of the sleeve beam 2 is connected with a U-shaped connector 23, and the U-shaped connector 23 is provided with a horizontal screw hole 25 and two vertical screw holes 24, and the hook bolt 22 is connected with the vertical screw hole. The U-shaped connectors are connected, and the pulley line hanging rod 21 is connected with the U-shaped connectors through horizontal screw holes.

[0017] The middle beam 1 is symmetrically provided with four long oval screw holes 11 , and the front end of the cover beam is provided with scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com