A pre-refrigerant compression skid-mounted module for liquefied natural gas

A technology of liquefied natural gas and pre-refrigerant, applied in liquefaction, refrigeration and liquefaction, equipment loaded into pressure vessels, etc., can solve problems such as difficult reasonable layout and installation, high lubricating oil temperature, increased process resistance, etc., to achieve space The effect of improving utilization rate, shortening pipeline length and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through specific embodiments.

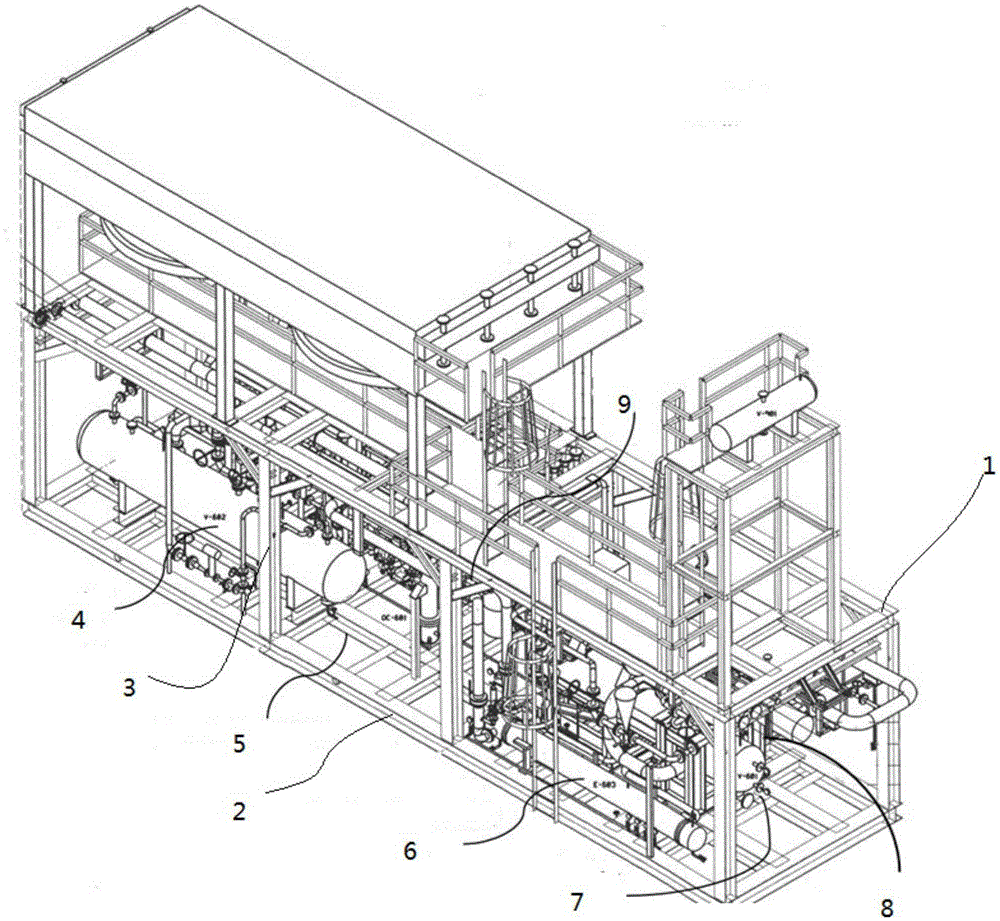

[0016] Such as figure 1 As shown, a pre-refrigerant compression skid-mounted module for liquefied natural gas includes a skid-mounted frame, a pre-refrigerant compressor 7, a compressor lubrication system 8, and a lubricating oil cooling heat exchanger integrated on the skid-mounted frame 6. Pre-refrigerant filter, compressor lubricating oil fine separator 5 and pre-refrigerant storage tank 4.

[0017] The skid-mounted frame is in the shape of a rectangular parallelepiped. The skid-mounted frame includes a bottom frame 2, a top frame 1, and eight intermediate connecting rods 3 connecting the top frame 1 and the bottom frame 2, the bottom frame 2, the top frame 1 and the connecting rods. 3 are welded and fixed to each other. The eight middle connecting rods 3 are evenly distributed on both sides of the bottom frame 2 and the top frame 1. The middle connecting rods 3 divide the ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com