The fastening structure of the atm machine through the wall cover

An ATM machine and fastening structure technology, applied in the field of automatic deposit and withdrawal machines, can solve the problems of affecting safety, increasing production costs, and many structural parts, and achieve the effect of improving assembly efficiency and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

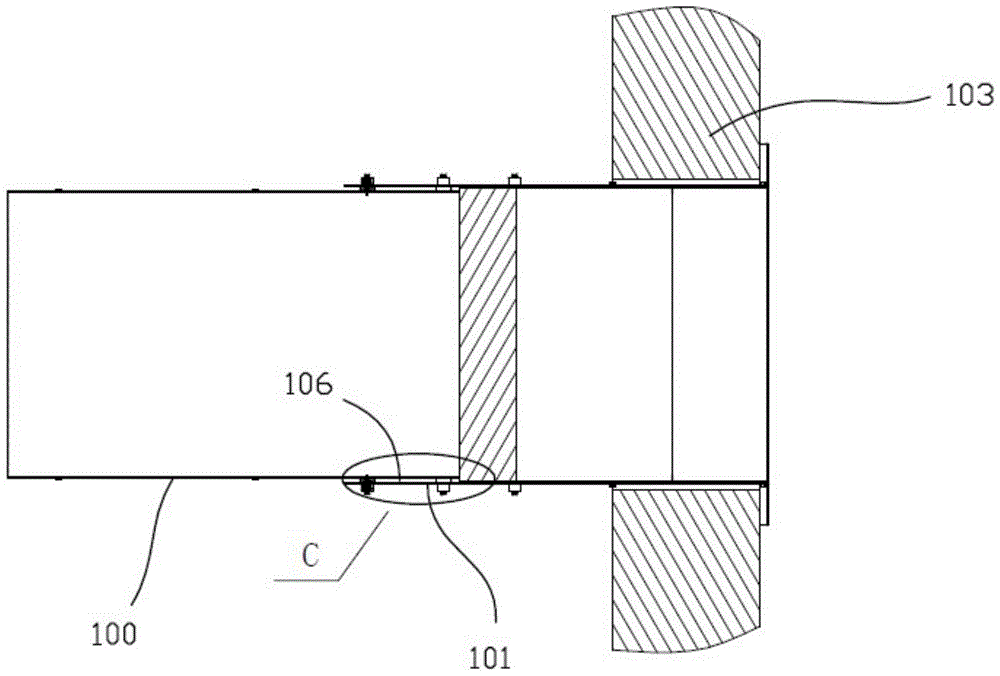

[0019] The present invention mainly uses pads and pressing parts to cooperate with sliding grooves on the wall penetration cover, and then uses fastening screws to fix the wall penetration cover on the frame. Compared with the existing fixing methods, not only the assembly efficiency is high, but also However, the safety can be guaranteed, and the structure and realization principle of the present invention will be further described below with specific embodiments.

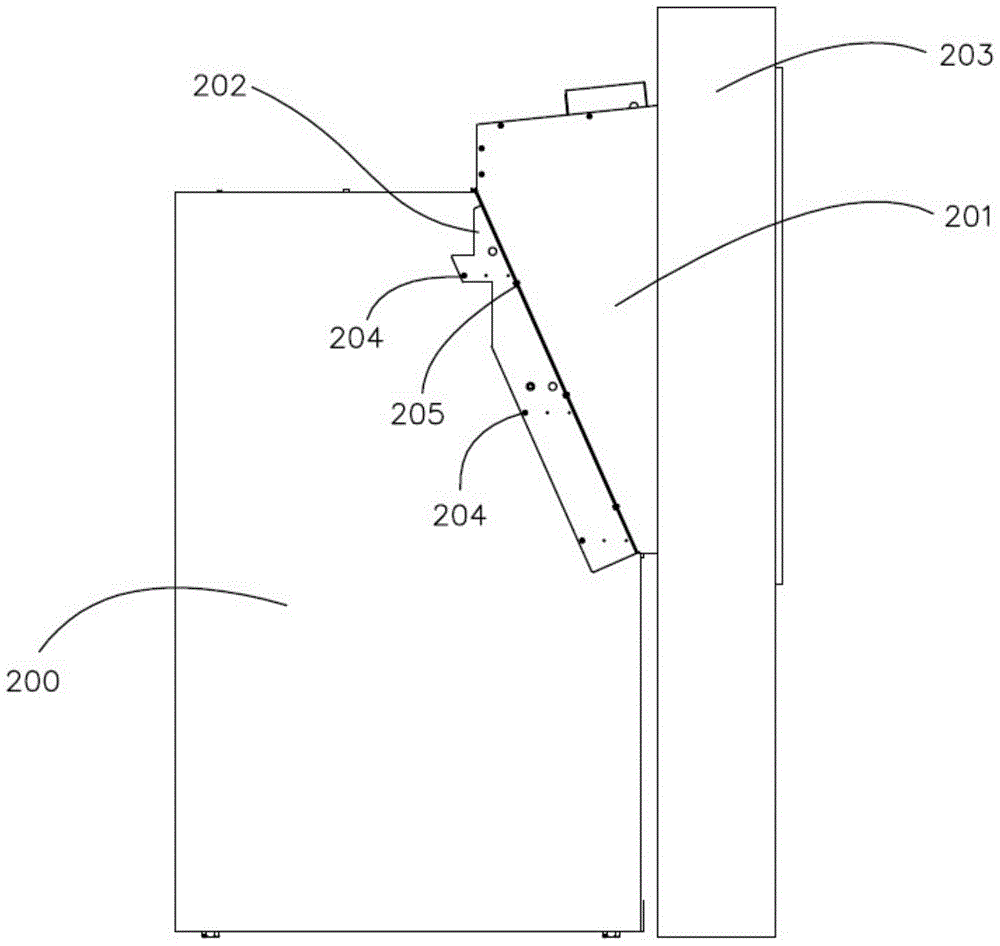

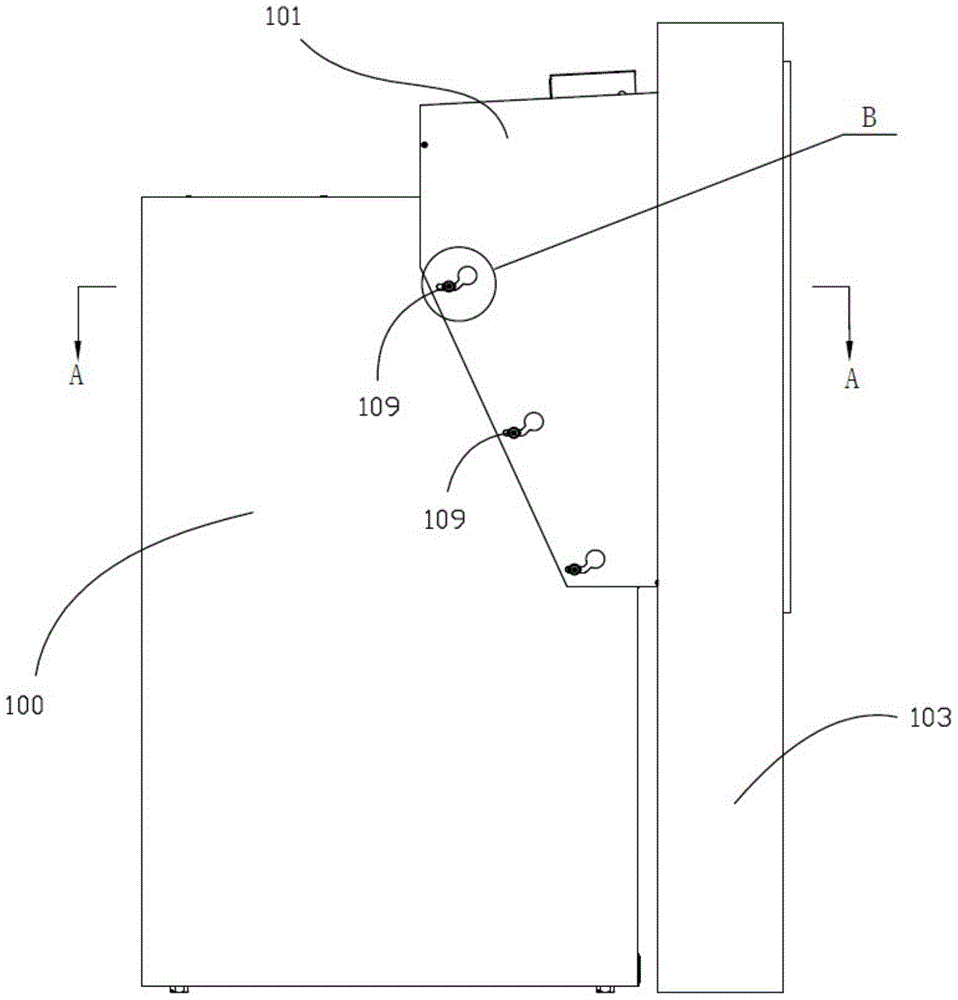

[0020] See 2 and image 3 As shown, the frame 100 of the ATM machine is arranged on the inside of the wall 103, a part of the wall penetration cover 101 is embedded in the inside of the wall body 103, and the other part extends out of the inside of the wall body 103, and the wall penetration cover 101 is located at the wall body 103 The outer part is the window for the user to operate. The part of the wall penetration cover 101 extending to the inside of the wall body 103 and the frame 100 are fixed by a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com