Electric control concrete hopper

A concrete and ash hopper technology, which is applied in construction, building structure, and construction material processing, can solve the problems of uncontrollable concrete blanking, inappropriate opening of sealing plates, and waste of concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

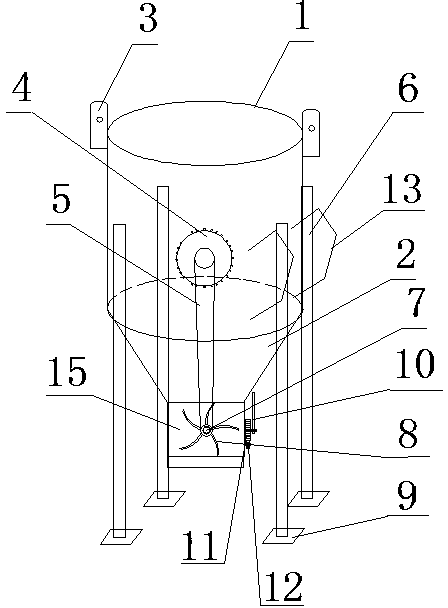

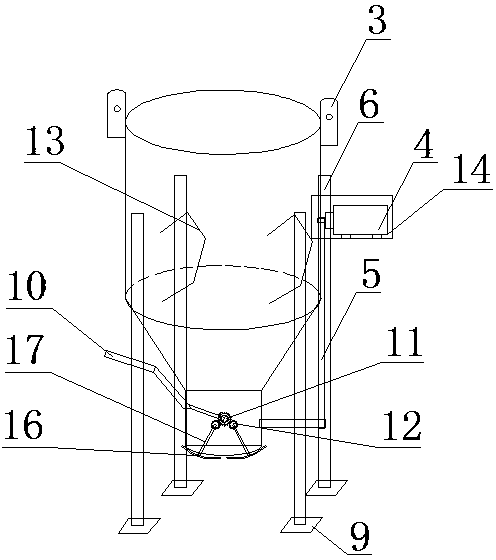

[0013] The embodiment of the present invention will be further elaborated below in conjunction with the accompanying drawings: a concrete ash hopper with electric control for discharging, which is made of steel plates. The steel plate cylinder 1 and the steel plate inclined cylinder 2 are welded and fixed as a whole. Finally, it is necessary to polish the inner and outer sides of Hankou to avoid the formation of concrete nodules caused by residual concrete at the inner interface during use. The lower part of the steel plate inclined cylinder 2 is the discharge port 15, and the rotating shaft 7 and the rotating impeller 8 are installed in the discharge port 15. Inside, the turning bar 10, the bull gear 11, the pinion 12, the connecting rod 16, the sealing bottom plate 17, the connecting rod 16 and two small gears 12 are installed in the blanking port 15, and the sealing bottom plate 17 is laterally welded on the blanking port 15 edges, The big gear 11 and the two small gears 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com