External baffle-block anti-floating method for reinforced concrete pool

A technology of reinforced concrete and stoppers, applied in protection devices, building types, buildings, etc., can solve the problems of high construction costs, achieve good technical effects, save engineering anti-floating costs, and have good anti-floating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

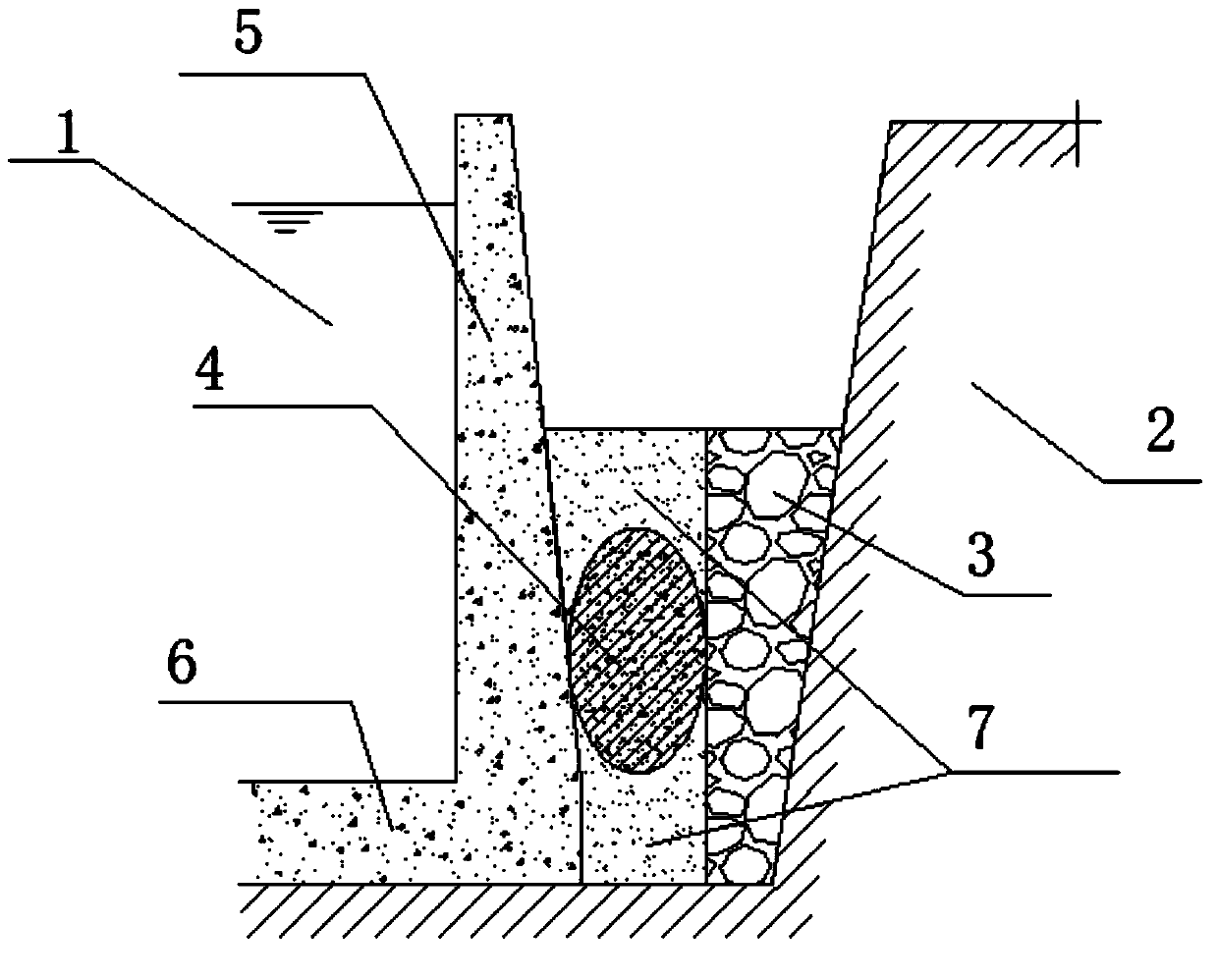

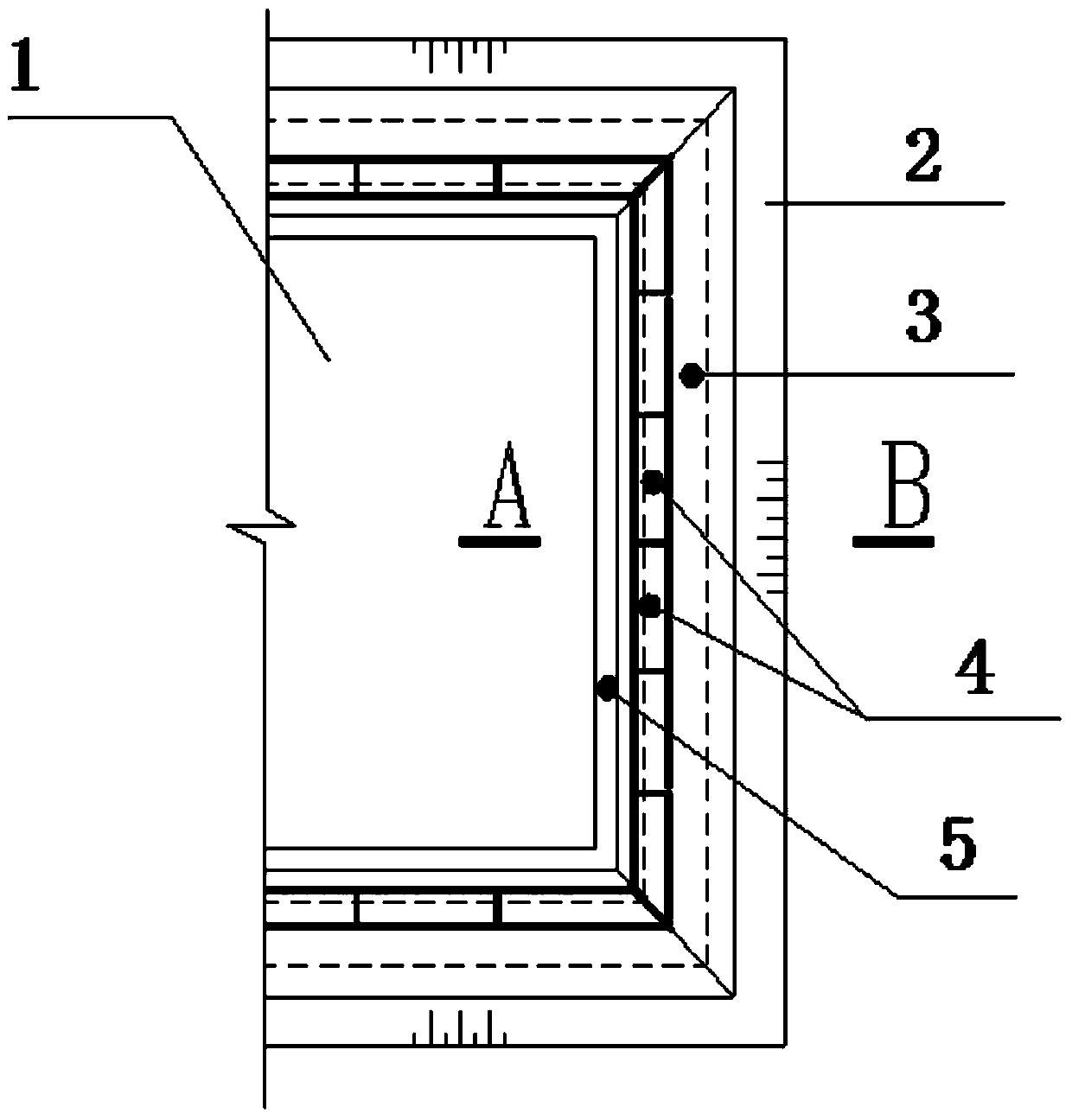

[0018] When constructing a reinforced concrete pool, according to figure 1 , figure 2 In the method shown, an elliptical cross-sectional block is set between the pool wall and the retaining wall. The pool length is 30 meters, the width is 25 meters, and the depth is 5 meters. It is 0.25 meters, and the lower end is connected with the bottom plate of the pool. According to the calculation of the side pressure of the pool wall, the width is 0.5 meters. The thickness of the pool wall increases linearly from the upper end to the lower end. The inclination angle of the outer side of the pool wall is 87 degrees. The body is hard, and its geotechnical engineering test standard penetration index is not less than 20 hits. A mortar block stone retaining wall is set on the soil surface on the side facing the pool wall, and the surface of the retaining wall is a natural rough surface of block stone. The section size of the retaining wall is 3.0 meters high, 1.0 meters wide at the top, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com