Method for evaluating resistance spot welding spattering quantitatively in real time through acoustic emission signal frequency spectrum

An acoustic emission signal and resistance spot welding technology, which is applied to resistance welding equipment, measuring devices, welding equipment, etc., can solve the problems of lack of quantitative detection and evaluation methods, and the difficulty of detecting the quality of resistance spot welding solder joints, etc., to achieve fast detection and Evaluation, evaluation method is simple, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The workpiece to be welded is the overlapping joint of two galvanized steel sheet structures with a thickness of 1mm. The main welding process parameters used are: the welding current is 9000A, the duration of the welding current is 8 cycles, and the electrode pressure is 0.15MPa.

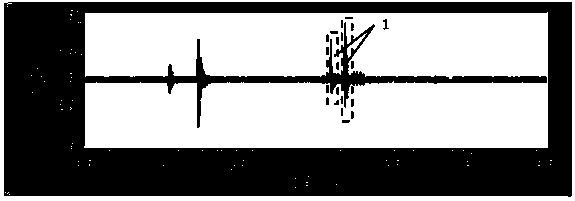

[0038] During welding, the structural load acoustic emission signal of the resistance spot welding process is collected in real time, and the dynamic curve of the structural load acoustic emission signal is drawn by the analysis software, as shown in figure 1 shown.

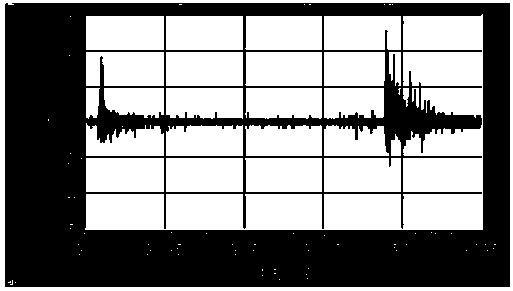

[0039] Different stages of the welding process can be identified from the waveform diagram, and the figure 1 Weld spatter signal 1 in the figure 2 shown. It can be seen that the mode of the welding spatter is a welding spatter event of two acoustic emission events.

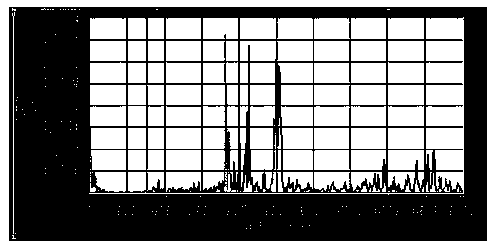

[0040] Calculate the self-power spectrum of the acoustic emission signal in the welding spatter process, and draw the self-power spectrum, such as image 3 s...

Embodiment 2

[0044] The workpiece to be welded is the overlapping joint of two galvanized steel sheet structures with a thickness of 1mm. The main welding process parameters used are: welding current is 10000A, welding current duration is 8 cycles, and electrode pressure is 0.15MPa.

[0045] During welding, the structural load acoustic emission signal of the resistance spot welding process is collected in real time, and the dynamic curve of the structural load acoustic emission signal is drawn by the analysis software, as shown in Figure 4 shown.

[0046] Different stages of the welding process can be identified from the waveform diagram, and the Figure 4 Weld spatter signal 2 in, such as Figure 5 shown. It can be seen that the mode of the welding spatter is a welding spatter event of a single acoustic emission event.

[0047] Calculate the self-power spectrum of the acoustic emission signal in the welding spatter process, and draw the self-power spectrum, such as Figure 6 shown. ...

Embodiment 3

[0051] The workpiece to be welded is the overlapping joint of two galvanized steel sheet structures with a thickness of 1 mm. The main welding process parameters used are: welding current is 11000A, welding current duration is 8 cycles, and electrode pressure is 0.15MPa.

[0052] During welding, the structural load acoustic emission signal of the resistance spot welding process is collected in real time, and the dynamic curve of the structural load acoustic emission signal is drawn by the analysis software, as shown in Figure 7 shown.

[0053] Different stages of the welding process can be identified from the waveform diagram, and the Figure 7 Weld spatter signal 3 in, such as Figure 8 shown. It can be seen that the mode of the welding spatter is a welding spatter event of two acoustic emission events.

[0054] Calculate the self-power spectrum of the acoustic emission signal in the welding spatter process, and draw the self-power spectrum, such as Figure 9 shown.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com