Dual channel multi-stage jet sampling pigtail

A dual-channel, jet tube technology, applied in the direction of extracting undisturbed core devices, earth cube drilling, etc., can solve the problems of prolonged sampling time, small sampling volume, and inability to take out samples, etc., and achieve the effect of increasing the airflow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

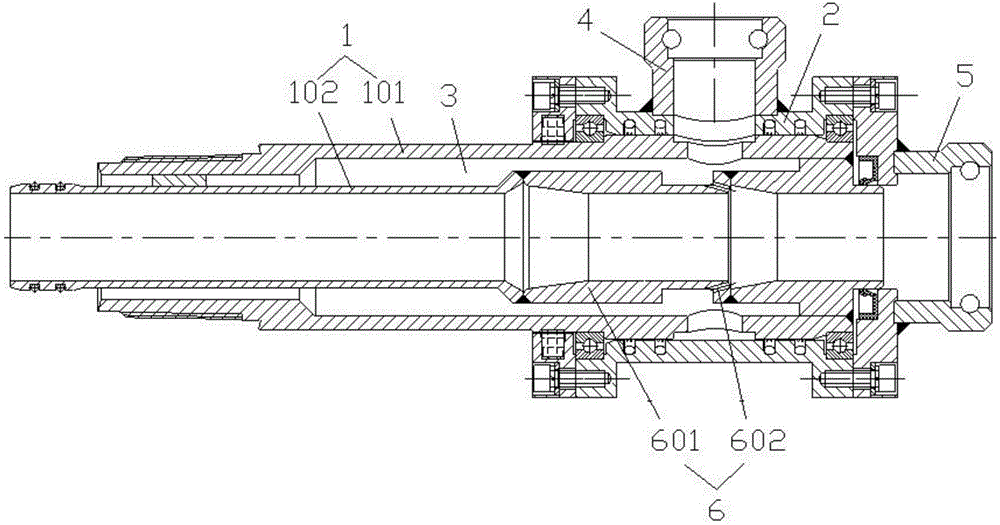

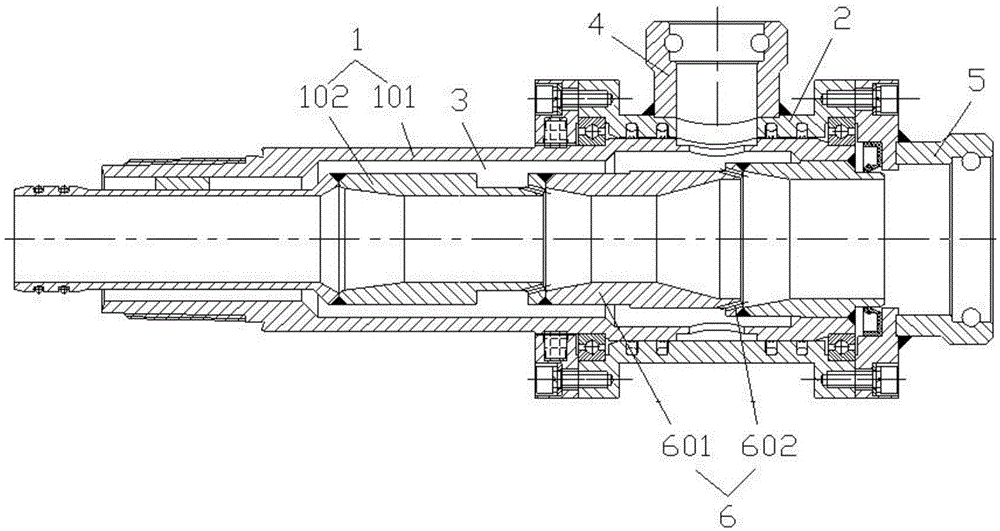

[0019] Embodiment one: if figure 1 As shown, the dual-channel multi-stage injection sampling pigtail in this embodiment includes a double-walled pipe body 1 and a housing 2 that is sheathed on the double-walled pipe body 1, and the housing 2 and the double-walled pipe body 1 are rotatably fitted;

[0020] The double-wall pipe body 1 includes an outer pipe wall 101 and an inner pipe wall 102, the annular channel 3 between the outer pipe wall 101 and the inner pipe wall 102 is closed at the rear end of the pipe body, and the outer pipe wall 101 and the inner pipe wall The front end of the pipe wall 102 is provided with a connecting structure connecting the double-walled drill pipe. The connecting structure in this embodiment includes an external thread arranged at the front end of the outer pipe wall 101 and an annular protrusion arranged at the front end of the inner pipe wall 102;

[0021] The housing 2 is provided with a first quick joint 4 communicating with the annular chan...

Embodiment 2

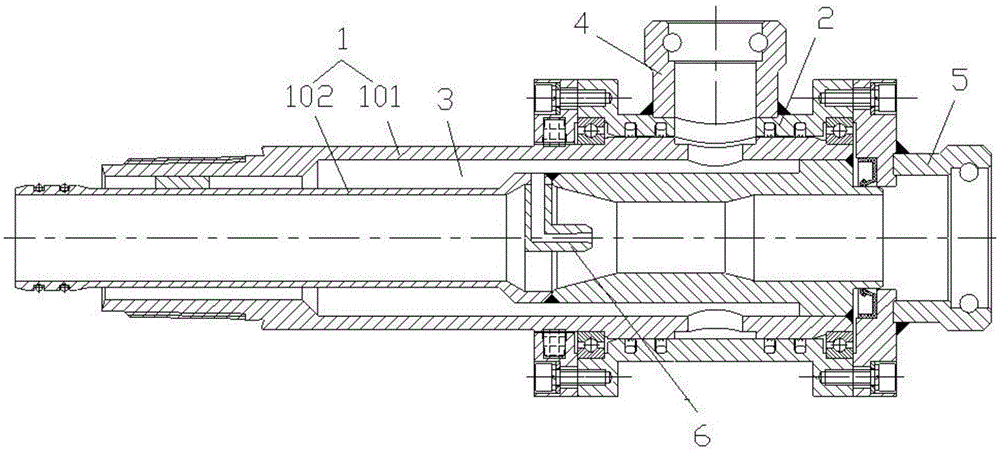

[0026] Embodiment two: if image 3 As shown, the difference between this embodiment and Embodiment 1 is that the injector 6 is a central injector, and the central injector 6 is an injection tube located in the tube hole of the inner tube wall 102, and the injection medium of the injection tube The inlet communicates with the annular channel 3 between the outer pipe wall 101 and the inner pipe wall 102; other structures of this embodiment are the same as those of the first embodiment, and will not be repeated here. The central injector in this embodiment is a single-stage central injector composed of a single injection tube. Of course, the central injector described in different implementations can also be arranged in parallel axially along the inner tube wall 102 by several injection tubes. A multi-stage central injector (such as Figure 4 As shown), the multi-stage injector can form a higher negative pressure in the tube hole of the inner tube wall 102, which is beneficial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com