A reusable electrically heated moldable anti-shock and anti-extrusion packaging

An anti-extrusion, electric heating technology, applied in the direction of transportation and packaging, containers and containers to prevent mechanical damage, can solve the problems of waste, environmental pollution, low reuse rate of outer packaging, etc., to improve the utilization rate and alleviate pollution effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

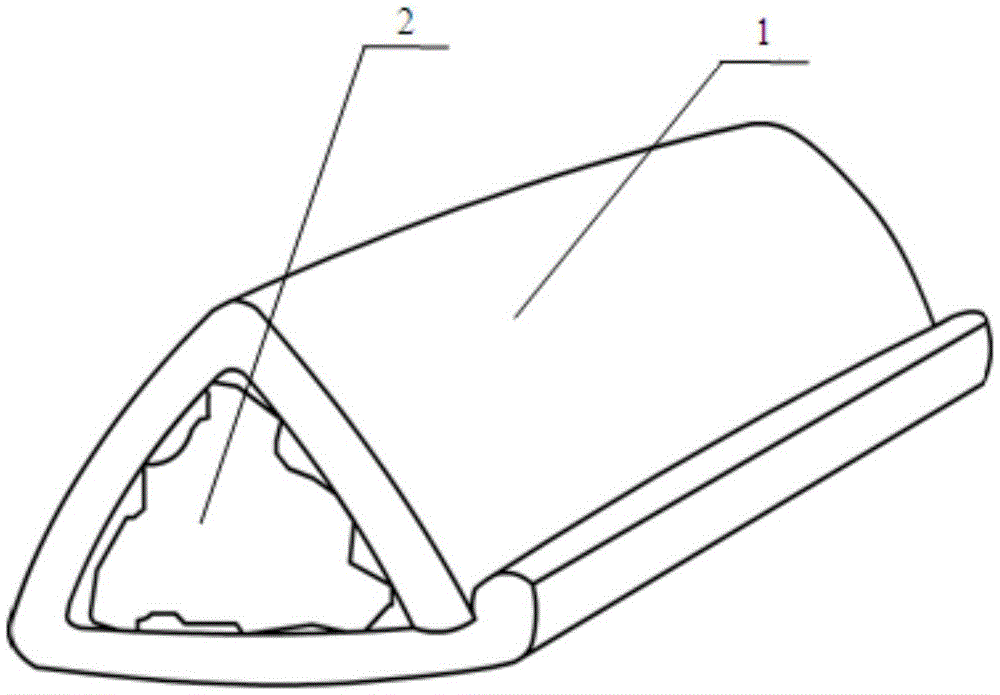

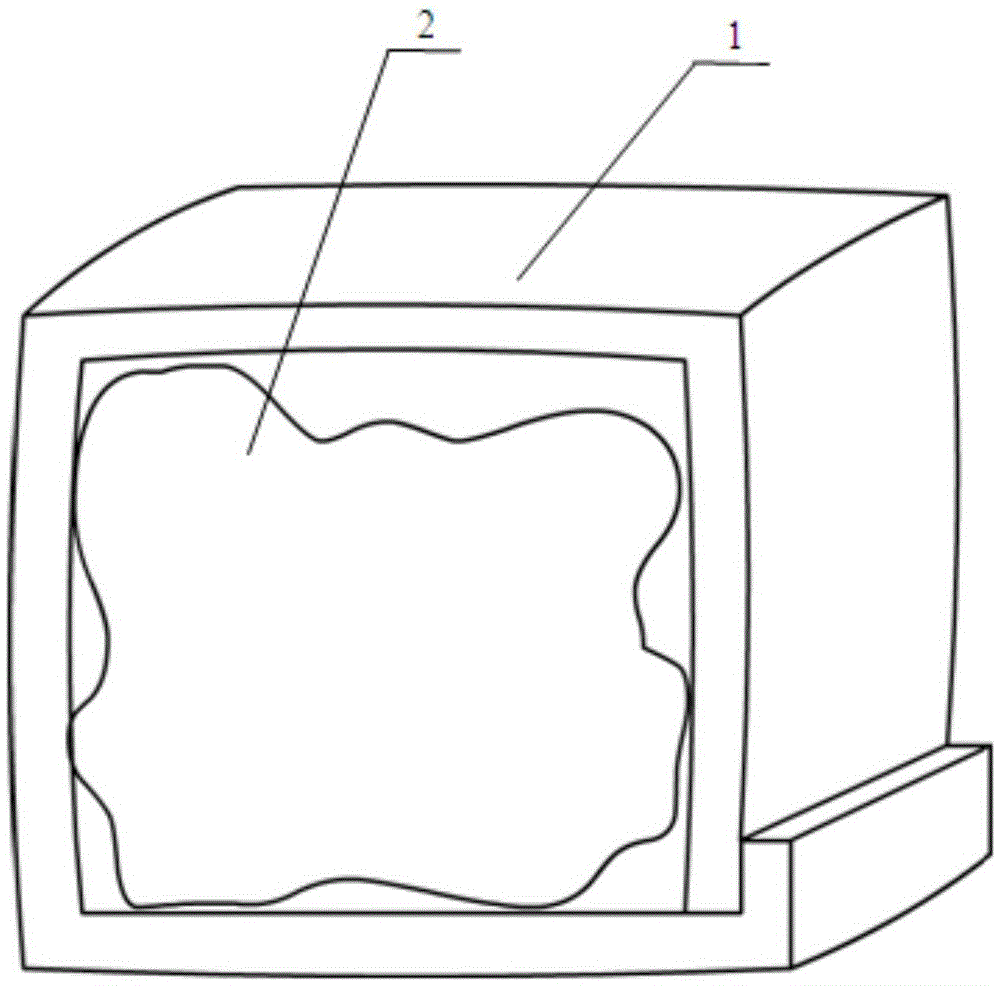

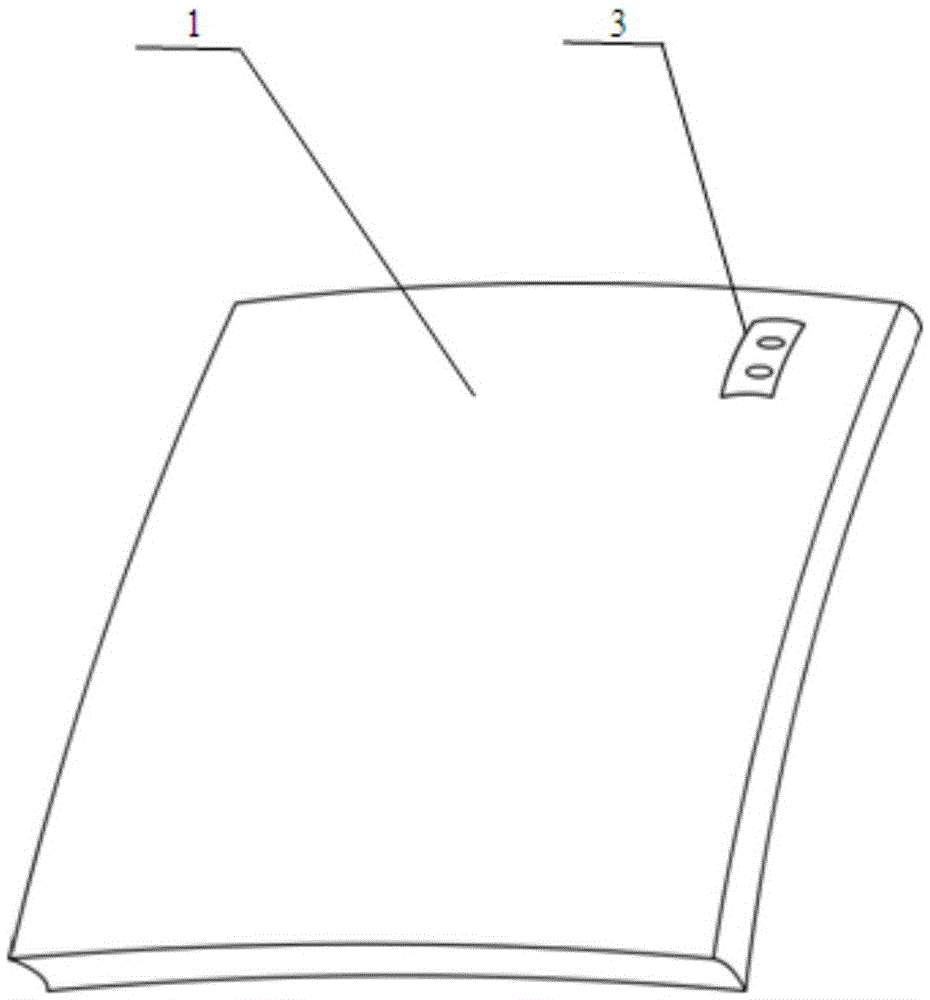

[0024] Such as figure 1 and figure 2 As shown, a reusable electrically heated plastic anti-shock and anti-extrusion package includes a thermoplastic main body 1 , a heating device plug interface 3 and a heating device heating wire 4 . During use, first turn on the power supply, and the heating device heating wire 4 heats the thermoplastic main body part 1 to make it softened by heat, and the present invention is adjusted to the required shape or coated on the object 2 to be protected, because of its weight, it is pressed into any shape. shape, like casting molds, such as figure 1 the triangle, figure 2 square, or any other shape, after cooling for a period of time, the anti-shock and anti-extrusion transport package that the user wants to achieve conforms to the shape and size of the object 2 to be protected. After use, turn on the power again, the heating device heats the thermoplastic main body part 1 to make it softened by heat, and the package of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com