Automatic opening adjusting mechanism

An automatic adjustment and support plate technology, applied in packaging and other directions, can solve the problems of increasing labor fatigue, unable to meet the market environment, low work efficiency, etc., and achieve the effect of reducing labor fatigue, simple and convenient operation, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

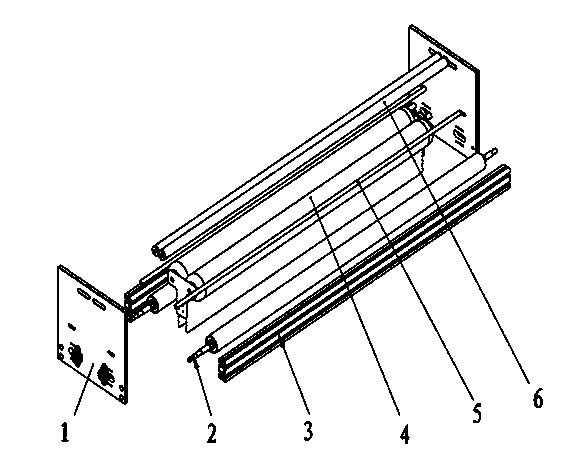

[0015] Such as figure 1 As shown, the automatic adjustment stretching mechanism is provided with a floating steel pipe mechanism 4 between the two side plates 1, a tightened wire rod 6 is arranged directly above the floating steel pipe mechanism 4, and a wire rod 6 is arranged between the wire rod 6 and the floating steel pipe mechanism 4. interval, both sides of the upper end of the floating steel pipe mechanism 4 are provided with a guide shaft 5 that touches the floating steel pipe mechanism, and both sides of the lower end of the floating steel pipe mechanism 4 are provided with a roller mechanism 2 that touches the floating steel pipe mechanism. There is a roller mechanism groove for adjusting the stretching width on the top.

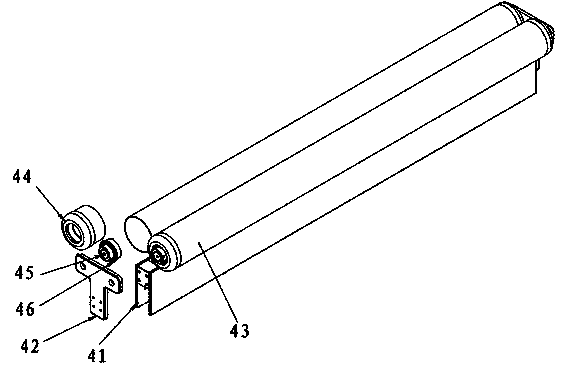

[0016] figure 2 As shown, the floating steel pipe mechanism 4 includes a support plate 41, a separation end plate 42 and a steel pipe 43, the two ends of the steel pipe 43 are covered with a steel pipe plug 44, and the steel pipe plug 44 is embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com