Supporting device capable of achieving rapid and continuous change of angle and bearing large load

A technology of supporting device and changing angle, which is applied in the direction of measuring device, engine test, machine/structural component test, etc. data and other issues, to achieve the effect of changing the angle quickly, accurately and continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

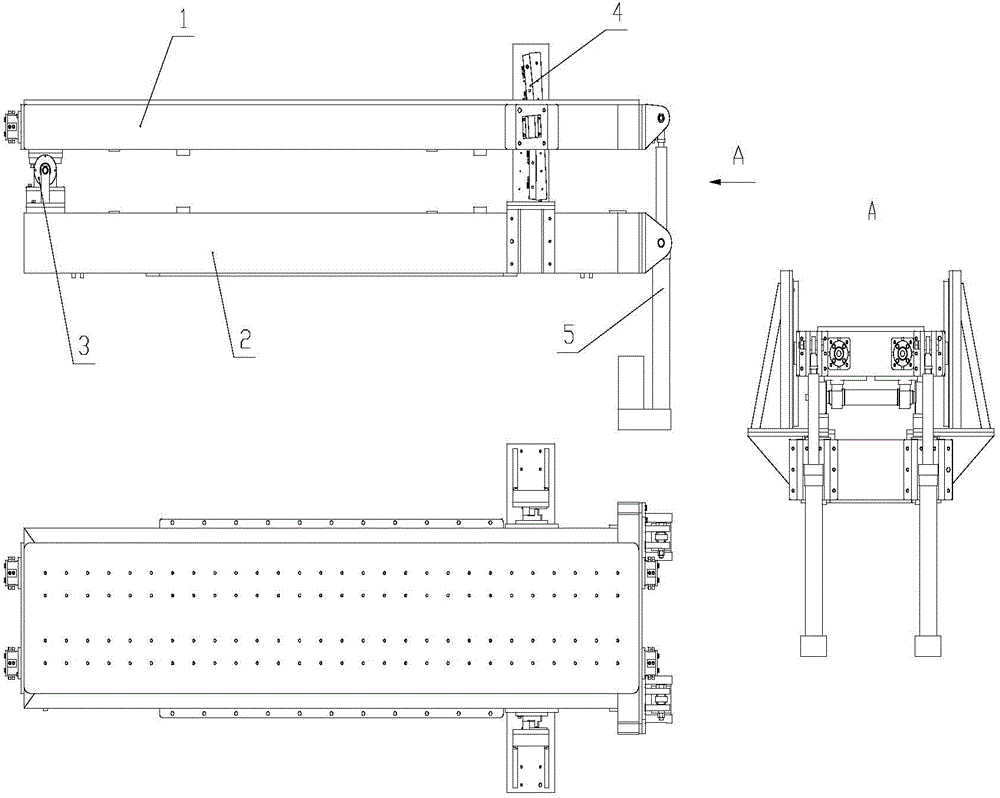

[0025] Such as figure 1 As shown, the present invention is made up of upper platform 1, lower platform 2, rotating shaft device 3, arc guide rail device 4 and driving device 5. Since the variable-angle support device needs to drive the test piece to rotate, the design of the device consists of upper and lower platforms. The lower platform 2 is a fixed part, which is connected to the installation foundation and is the support of the whole device. The upper platform 1 is installed on the lower platform through the rotating shaft device 3. 2, and can rotate relative to the lower platform 2; the upper platform 1 is a moving part: connected to the engine test piece, and rotates relative to the lower platform 2 around the rotating shaft; The center of rotation supports the upper platform 1 at the same time; the arc guide rail device 4: connects the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com