Portable low-leakage refrigerant recycling machine

A low-leakage, refrigerant-based technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of large volume of the whole machine, high purchase cost and assembly cost, easy leakage of connecting pipes, etc., to achieve small size and save energy. Procurement and assembly costs, accurate effects of pipeline control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

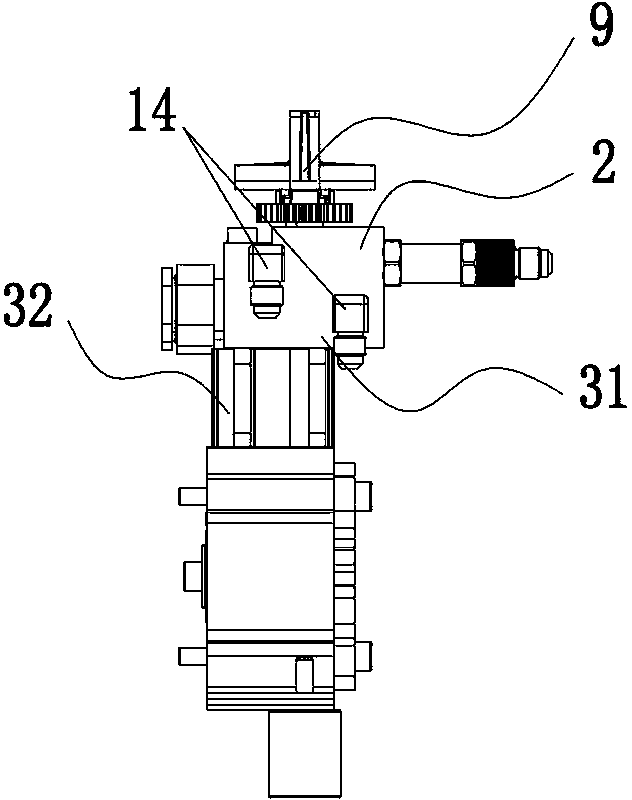

Image

Examples

Embodiment

[0024] When the recovery machine is in the self-cleaning mode, turn the knob 9 and drive the corresponding porous valve ball 12 to rotate through the driving and driven gears 10 / 11 and change the passage direction of the internal pipeline channel 13, so that the porous valve ball 12 is located at In the self-cleaning position, during the rotation process, the compressor 3 passes through the condenser 4, and then is compressed by the compressor 3 and is directly discharged from the output port of the compressor 3. During the whole process, the self-cleaning function is realized only by rotating the porous valve ball 12 . In the entire air channel, only the compressor 3 and the condenser 4 are externally installed, and the rest are located in the integrated control valve 2, thereby reducing the weight, volume and cost of the whole machine.

[0025] The above-mentioned technical solution is an example of a single-cylinder compressor, and can also be extended to double-cylinder, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com