Overhead correction adjuster for box-shaped steel columns in ultrahigh layer steel structure

A technology of correction and adjustment and steel structure, which is applied in the field of adjusters, can solve the problems of difficult construction, increase construction cost, and restrict construction progress, etc., and achieve the effects of fast construction methods, improved efficiency, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

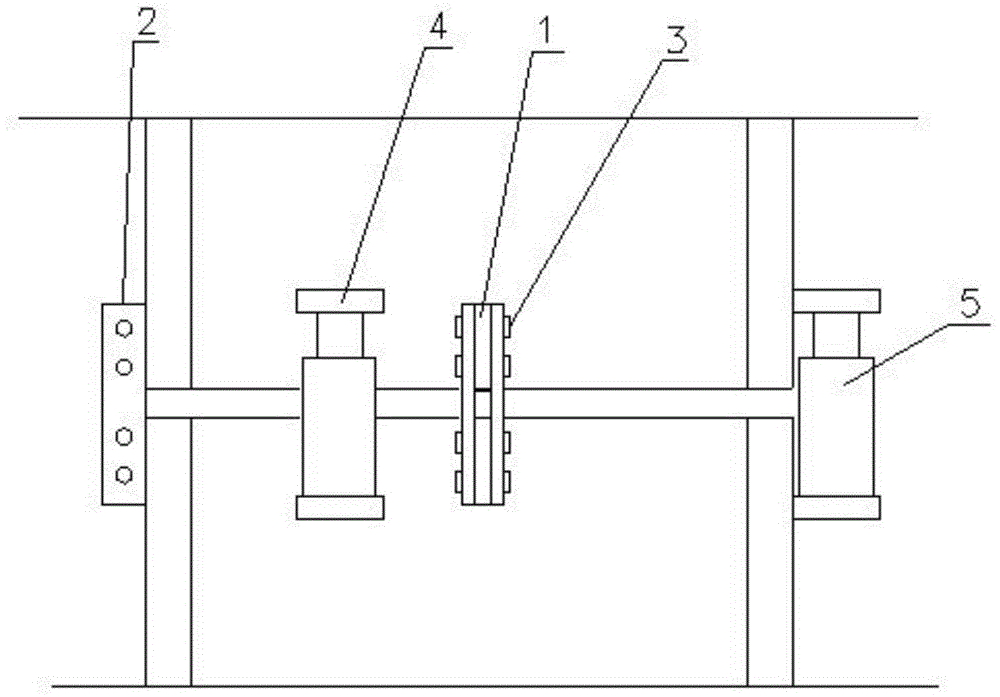

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0013] Four sets of connecting plates 1, eight splints 2 and 16 high-strength bolts 3 with a diameter of 20MM are welded firmly at the joints of the upper and lower columns respectively to ensure that the steel columns are not twisted or edged when docked at high altitude , in line with the requirements of the steel frame column docking specification; eight splints and 16 high-strength bolts with a diameter of 20MM are used in conjunction with the connecting plate to ensure the stability and safety of the steel frame column when docking at high altitude;

[0014] The upper and lower supporting plates of the four sets of adjusters are respectively welded to the upper and lower supporting plates used by the adjuster at the positions corresponding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com