Demoulding device

A technology of demolding device and sliding block is applied in the field of demolding device, which can solve the problems of incapable demolding and ejection of products, complex structure, etc., and achieve the effects of guaranteed mold life, low mold cost and strong structural reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

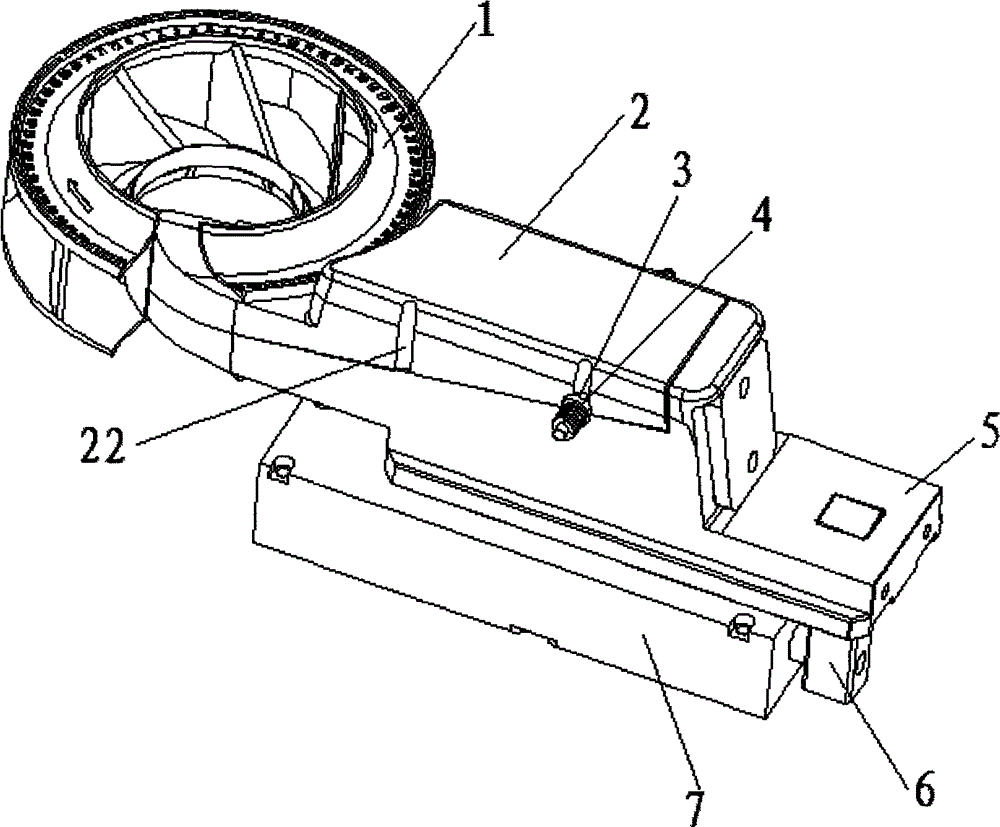

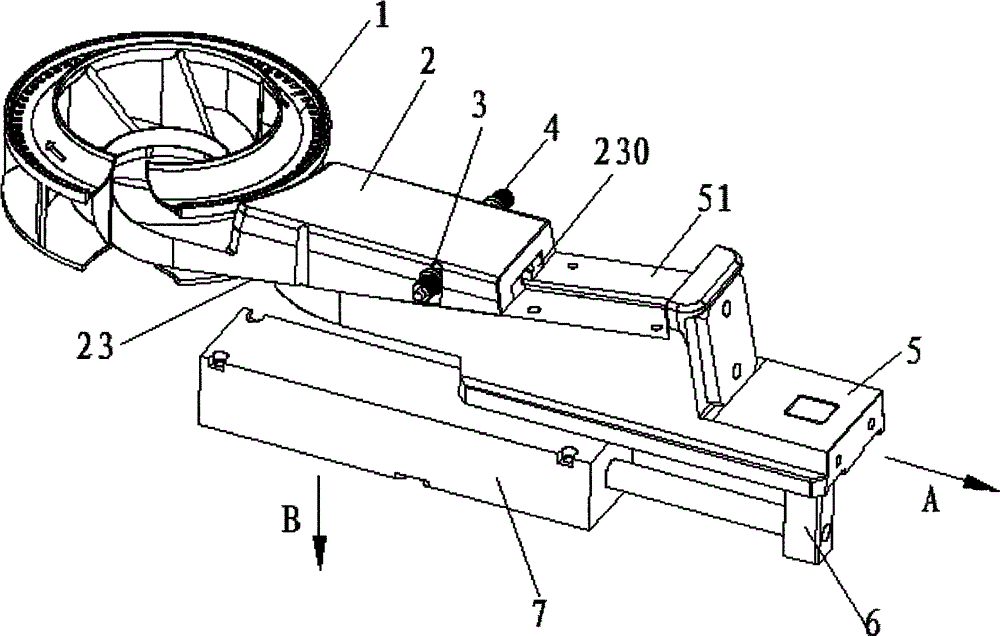

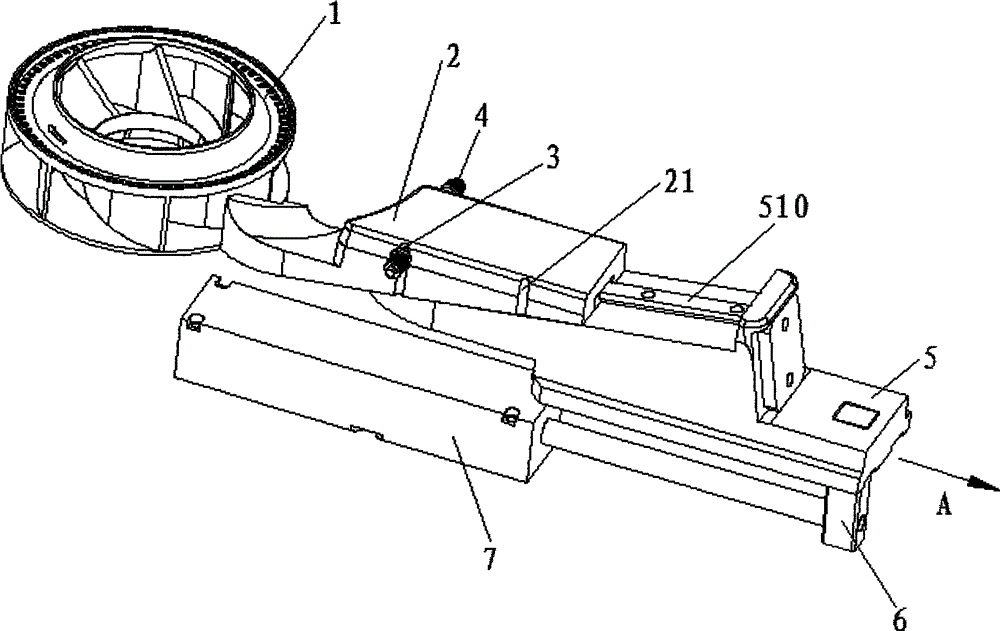

[0015] see Figure 1 to Figure 5 As shown, the demoulding device of the present invention is used for molding products 1 and includes a lower slider 5, an upper slider 2 assembled above the lower slider 5, a connecting rod 6 and a limit pin 52 assembled on the lower slider 5, assembled on The oil cylinder 7 on the connecting rod 6, the bead (not shown) positioned at both sides of the lower slider 5 and the dial ball 3 and the spring 4 assembled on the bead. The upper slider 2 and the lower slider 5 are connected together with the product 1 for forming the product 1 .

[0016] The upper slider 2 is assembled above the lower slider 5 and can slide relative to the lower slider 5 . The lower slider 5 is provided with an inclined top surface 51 . The top surface 51 is provided with a T-shaped guide rail 510 . The upper slider 2 is provided with an inclined bottom surface 23 assembled on said inclined top surface 51 . The bottom surface 23 is provided with a T-shaped sliding slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com