Light rail support keyway processing equipment and processing method

A groove processing and seat key technology, which is applied in the light rail support keyway processing equipment and processing field, can solve the problems of rising keyway processing costs, low efficiency of planer machines, and large equipment footprint, so as to improve processing efficiency and reduce labor intensity And the number of staffing, the effect of less floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

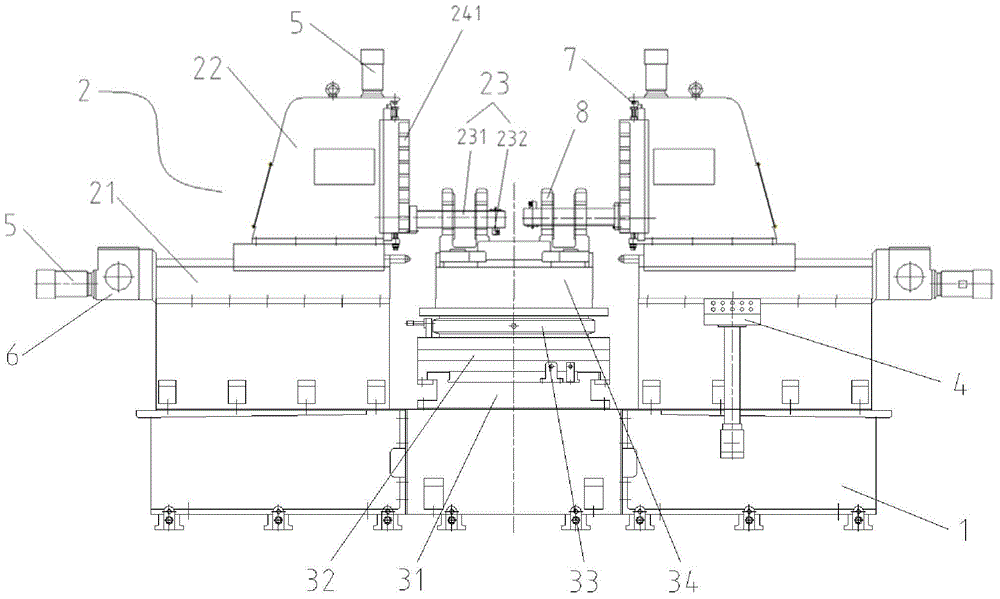

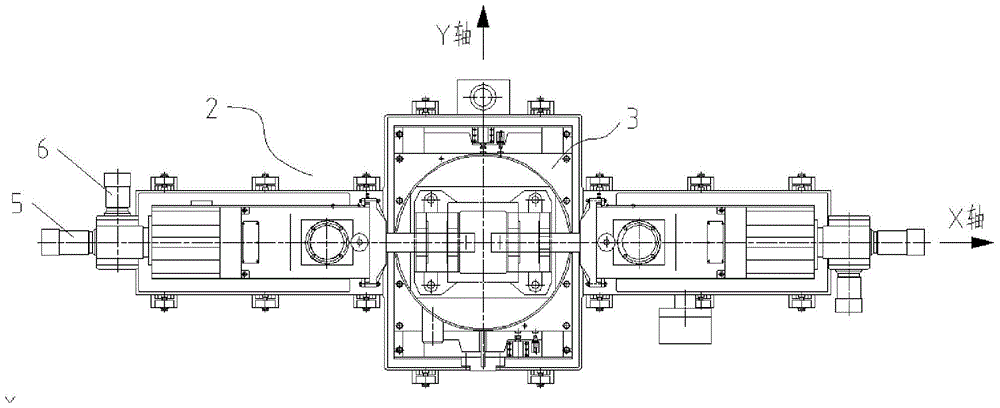

[0028] As shown in the figure, the light rail support keyway processing equipment according to the present invention includes a base 1, a horizontal sliding table assembly 2 arranged on the base 1 to move linearly along the X axis, a vertical sliding table assembly 3 to move linearly along the Y axis, and PLC console 4; the horizontal slide table assembly 2 includes a horizontal slide rail 21, a power head part set on the horizontal slide rail 21 and a transmission for driving the power head part to move left and right on the horizontal slide rail 21 Mechanism I; the power head components include a power head body 22, a milling cutter 23, a transmission mechanism II24 and a transmission mechanism III25, the milling cutter 23 includes a cutter bar 231 and a cutter head 232, and the transmission mechanism II24 drives the cutter bar 231 Moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com