Pinwheel cooling machine capable of automatically controlling sand temperature

A technology of cooling machine and pin wheel, which is applied in the direction of cleaning/processing machinery, manufacturing tools, casting and molding equipment, etc. Ensure normal production, avoid white mold burns, and increase power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

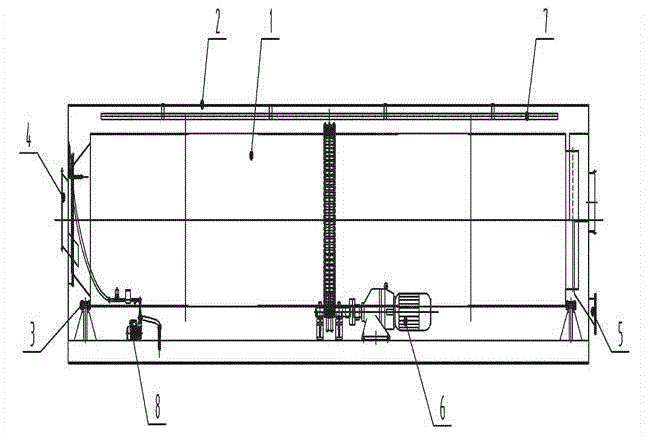

[0023] see figure 1 , in the figure, the needle wheel cooling machine with automatic sand temperature control of the present invention includes a drum 1, a drum cover 2 and a drum driving device 6, retaining wheels 3 are provided at the edges of both ends of the drum, and sand inlets are respectively provided at both ends of the drum. The mouth 4 and the sand outlet 5 are provided with a spray device 7 between the outside of the drum and the drum outer cover, and an automatic atomization cooling device 8 arranged inside the drum, and a fan interface 9 is provided at one end of the drum sand outlet.

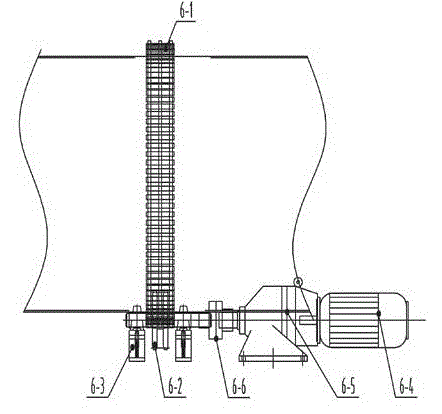

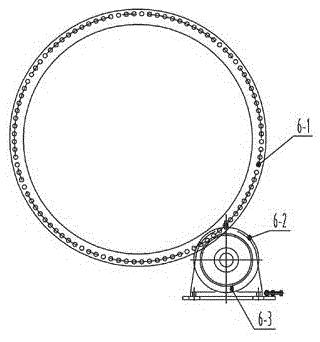

[0024] see Figure 2-4 , the drum driving device includes a transmission mechanism and a power mechanism, wherein the transmission mechanism includes a pair of pin chain rings 6-1 and a double-row sprocket 6-2 for meshing transmission, and the two sides of the rotating shaft of the double-row sprocket are rotatably supported on bearings And on the bearing seat 6-3.

[0025] see ...

Embodiment 2

[0034] see figure 2 , the structure of this embodiment is similar to that of Embodiment 1, and the same numbers represent the same meanings, which will not be repeated here. The difference is that the power mechanism described in this embodiment includes a motor 6-4 and a speed reducer 6-5 ; One end of the rotating shaft of the double-row sprocket is directly connected with the reducer through the coupling 6-6.

Embodiment 3

[0036] see Figure 8 , the structure of this embodiment is similar to that of Embodiment 1, and the parts with the same numbers represent the same meaning, so they will not be repeated here. The pipe 7-1 is provided with at least one row of spray holes 7-2 along the surface of the spray pipe towards the side of the drum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com