Bender of power transmission circuit externally exposed down lead

A technology for grounding down-conductors and transmission lines, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of time-consuming and labor-intensive bending of grounding down-conductors, and achieve the effects of fast and labor-saving bending process, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

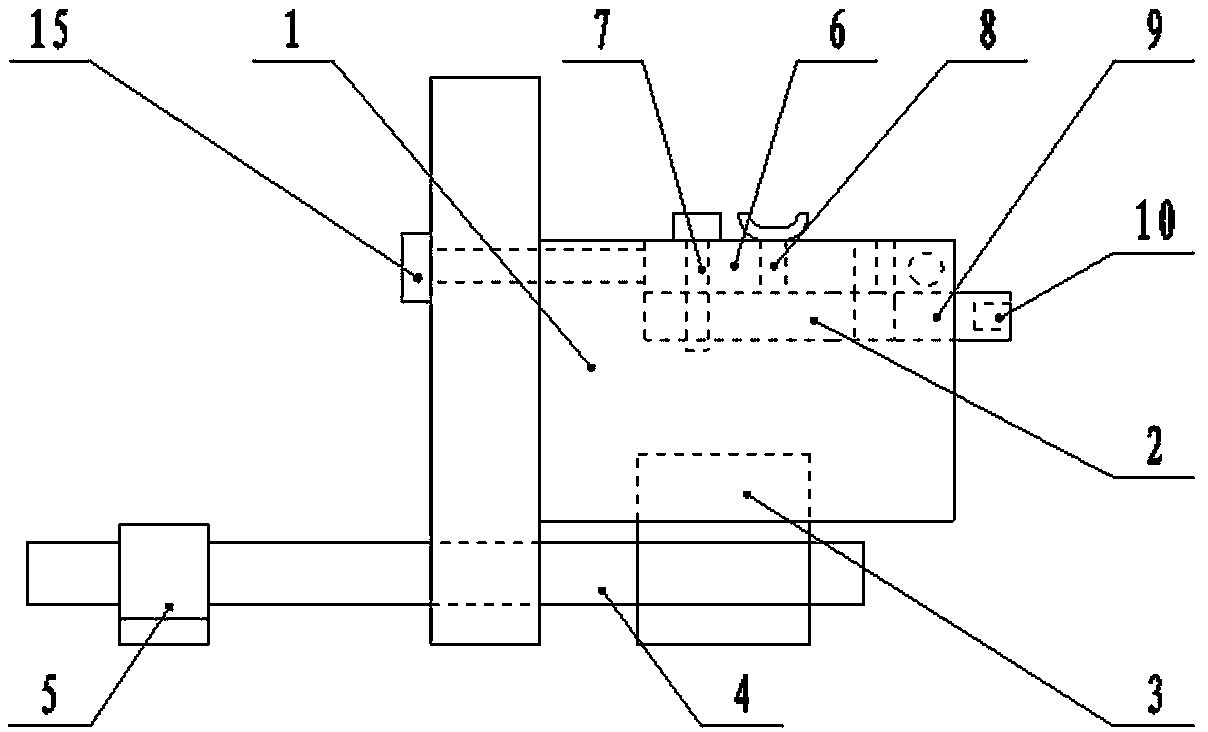

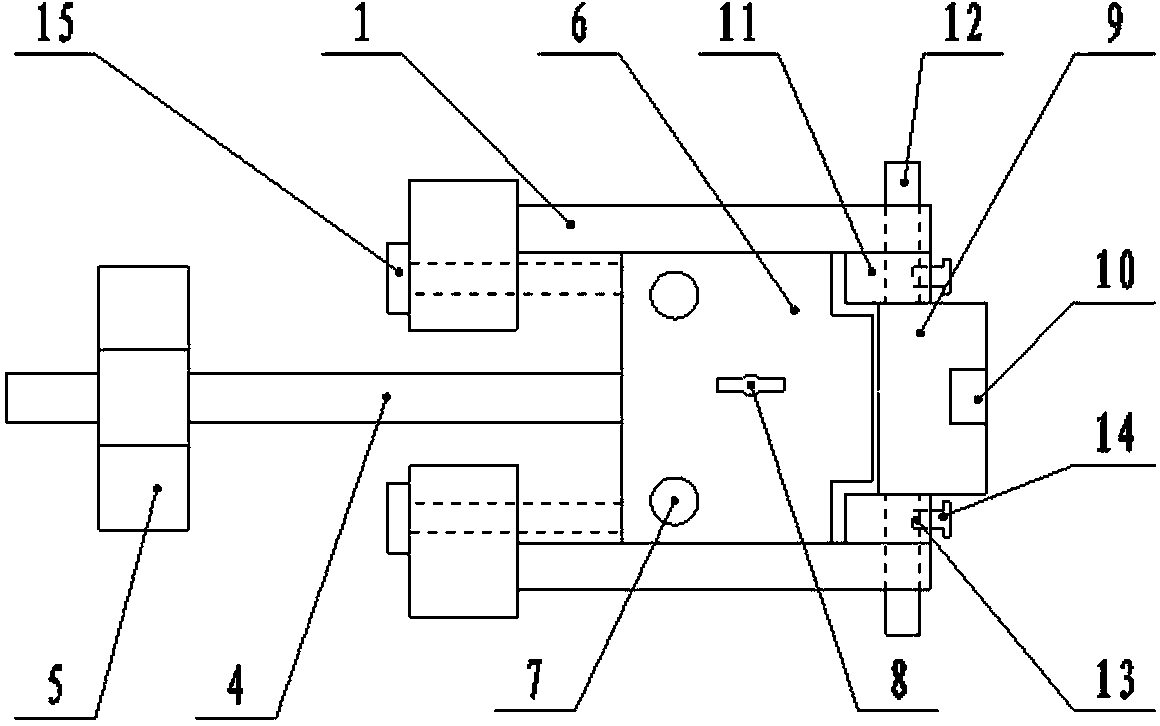

[0011] The exposed grounding down conductor bender of the transmission line includes two brackets 1 distributed front and rear, a support plate 2 is fixed between the two brackets 1, a connecting block 3 is arranged under the supporting plate 2, and a circle placed in the left and right directions is pierced inside the connecting block 3. Bar 4, the round bar 4 on the left side of the support plate 2 is covered with a pedal 5, the support plate 2 upper surface is placed with a pressing plate 6, the front and rear sides of the pressing plate 6 are screwed with locking bolts 7 passing through the support plate 2, and The pressure plate 6 is screwed with a top pressure bolt 8 in contact with the upper surface of the support plate 2. The front end of the support plate 2 is provided with a bending block 9 whose upper end surface is flush with it. The right end of the bending block 9 is provided with a bending hole 10. The bending block 9. A rotating plate 11 is fixed at the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com