Plug-in type electric connector and monitoring device for carbon crystal electric heating composite floors

A composite floor, electrothermal composite technology, applied in heating methods, electric heating systems, household heating and other directions, can solve the problems of confusing wires, inability to determine the location of faulty floors in time, slow construction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

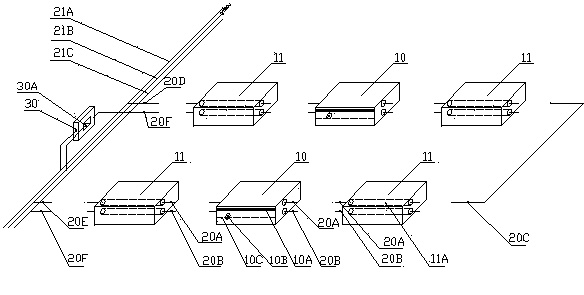

[0017] refer to figure 1 , the plug-in electrical connection of the carbon crystal electric heating composite floor of the present invention includes a composite floor and carbon crystal 10A, the composite floor includes multiple rows of composite floors arranged vertically or horizontally, and each row of composite floors contains a whole board placed in the middle 10 and an adjustable length plate 11 placed between the edge of the two ends of the whole plate 10 and the wall, and the length can be adjusted. The whole plate 10 is built with a carbon crystal 10A for heating the floor. Both ends of 11 are respectively equipped with power supply interface and communication interface, and the whole board 10 is also equipped with an electronic temperature measuring element 10B for monitoring the floor temperature and a flexible printed circuit board 10C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com