Die Bonding Method

A chip bonding and bonding technology, which is applied in the direction of instruments, welding equipment, optical mechanical equipment, etc., can solve problems such as fragmentation and chip bonding offset, and achieve the effect of improving quality, increasing yield, and reducing chip position changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The chip bonding method provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form, and are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

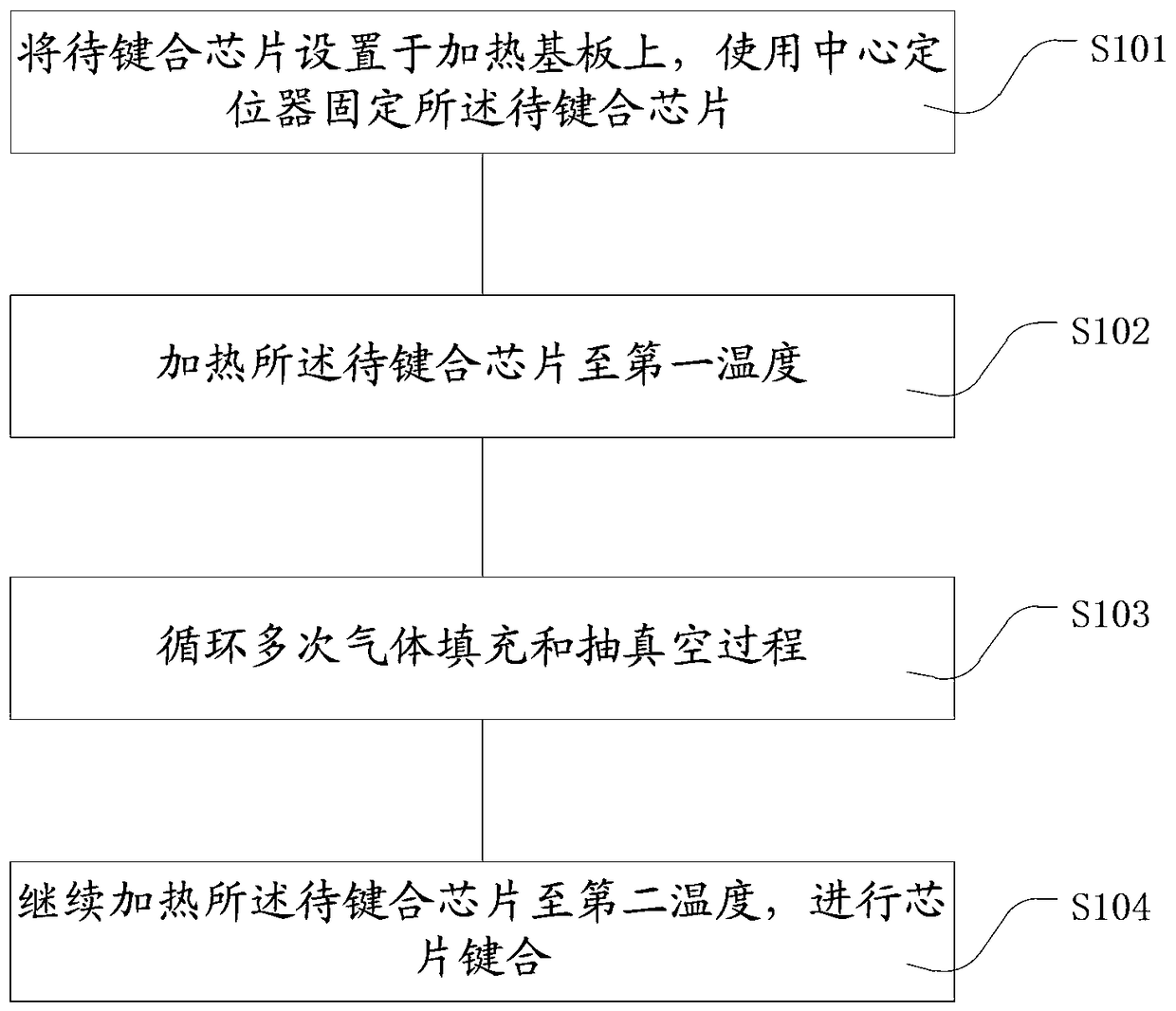

[0030] Please refer to figure 1 In the flow chart provided, the chip bonding method of this embodiment includes the following steps:

[0031] Step S101, placing the chip to be bonded on the heating substrate, and fixing the chip to be bonded with a center locator;

[0032] Step S102, heating the chip to be bonded to a first temperature;

[0033] Step S103, cycle multiple times of gas filling and vacuuming;

[0034] Step S104, continuing to heat the chip to be bonded to a second temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com