The method of hoisting the guide pipe with the lifting buckle device of the pouring pile concrete guide pipe

A buckle device and material guide tube technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of difficult hoisting and low efficiency of the material guide tube, so as to solve the problems of hoisting difficulties, solve low efficiency, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

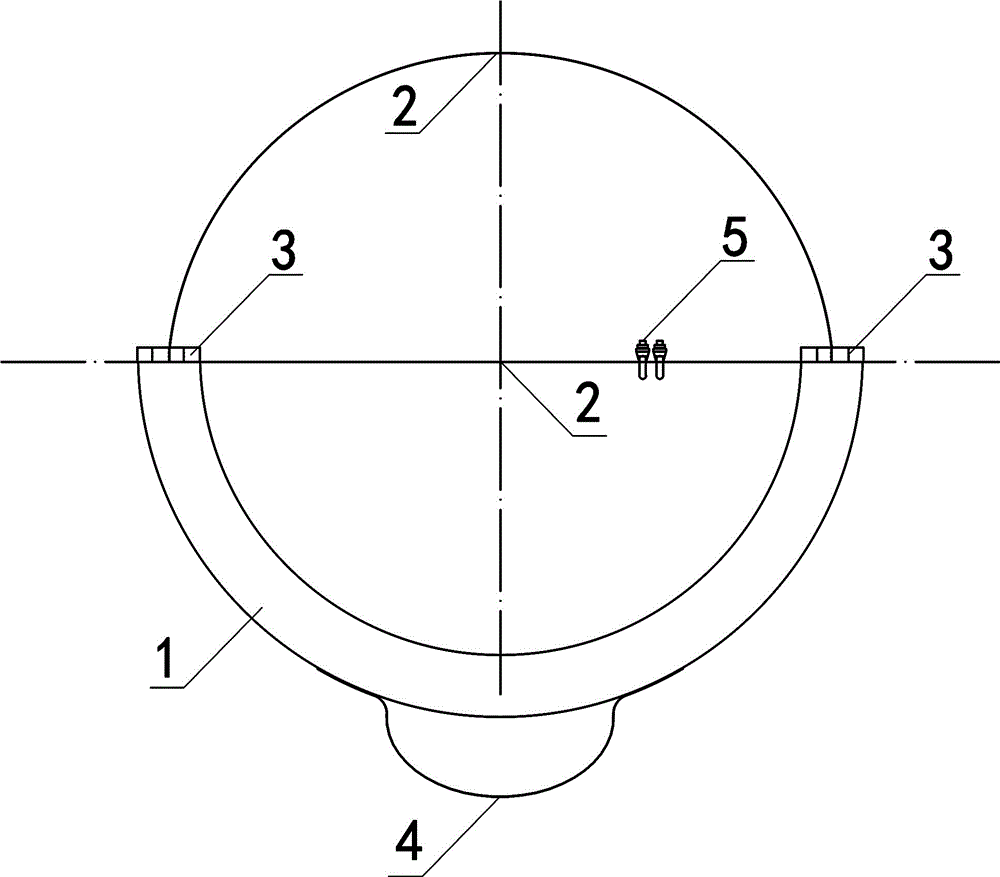

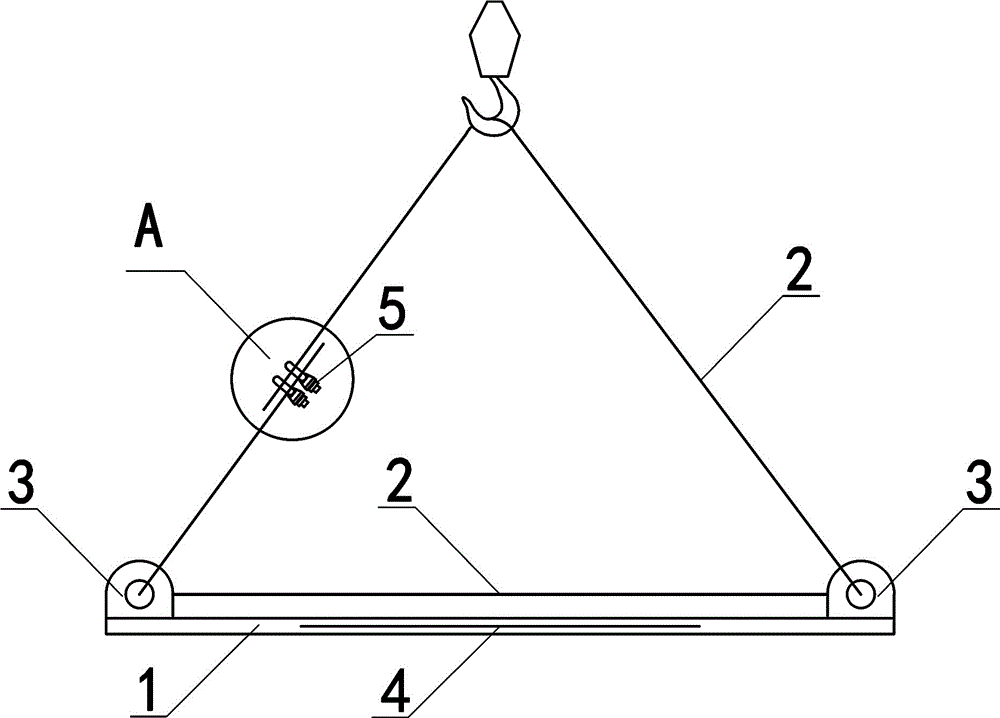

[0032] Such as Figure 1-9 Among them, a buckle device for hoisting a concrete guide pipe of a cast-in-place pile includes a steel wire rope 2. Two ends of the arc-shaped buckle 1 are provided with lifting rings 3, and the steel wire 2 passes through the back ends of the lifting rings 3 at both ends to be connected together. In use, the arc-shaped buckle 1 is located on one side of the guide tube 6, and the clamping ring of the steel wire rope 2 is located on the other side of the guide tube 6, and the vertical section is used to connect with the hook of the lifting device. When the hook pulls the wire rope 2 tightly, the wire rope 2 and the arc-shaped buckle 1 are about to clamp the guide tube 6 tightly and are axially limited at the stiffening ring 7. Thus, it is convenient to lift the guide tube 6.

[0033] The preferred structure is figure 1 , 4 7. In 7, the arc-shaped buckle 1 is semicircular, and the arc-shaped inner wall of the arc-shaped buckle 1 matches the outer wall of...

Embodiment 2

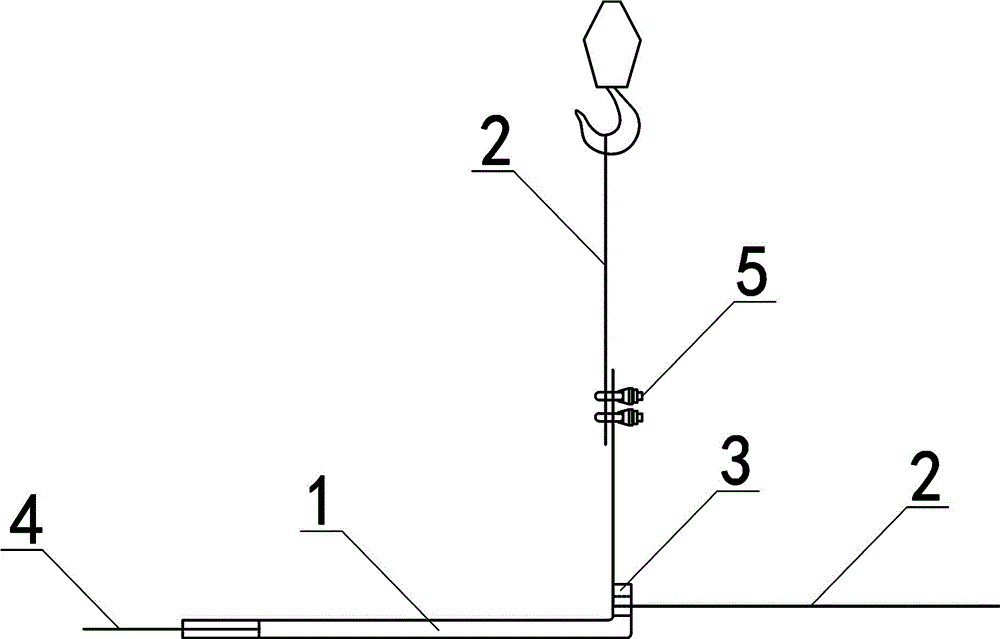

[0041] Such as Figure 7-9 Among them, a method for hoisting a guide tube by using the above hoisting buckle device includes the following steps:

[0042] 1. When installing or disassembling the guide tube 6, first fix the lower guide tube 6 in the hole to be poured into the pile hole through the U-shaped card 8; the U-shaped card is clamped on the guide tube 6, and There is also a sleeper (9) support at the bottom of the card.

[0043] 2. Set the arc buckle 1 and the steel wire rope 2 under the stiffening ring 7 of the guide tube 6 to be installed or removed;

[0044] 3. The wire rope 2 is hung on the hook of the hoisting equipment. When the hoisting equipment lifts the wire rope 2, the wire rope 2 is tightened, and the snap ring composed of the arc buckle 1 and the wire rope 2 is tightened to clamp the guide tube 6, and the guide tube 6 can be tightened. The material pipe 6 is hoisted and kept upright; such as Figure 7 Shown in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com