Painting equipment and technology of magnetic pigment

A technology of magnetic pigments and coating equipment, which is applied in the device, coating, printing and other directions of coating liquid on the surface, which can solve the problems affecting the development of the magnetic pigment effect ink coating market, the difficulty in making magnetic molds, and the many magnetic coating processes, etc. problem, to achieve the effect of strong magnetic three-dimensional effect, low cost of process transformation, and clear production pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

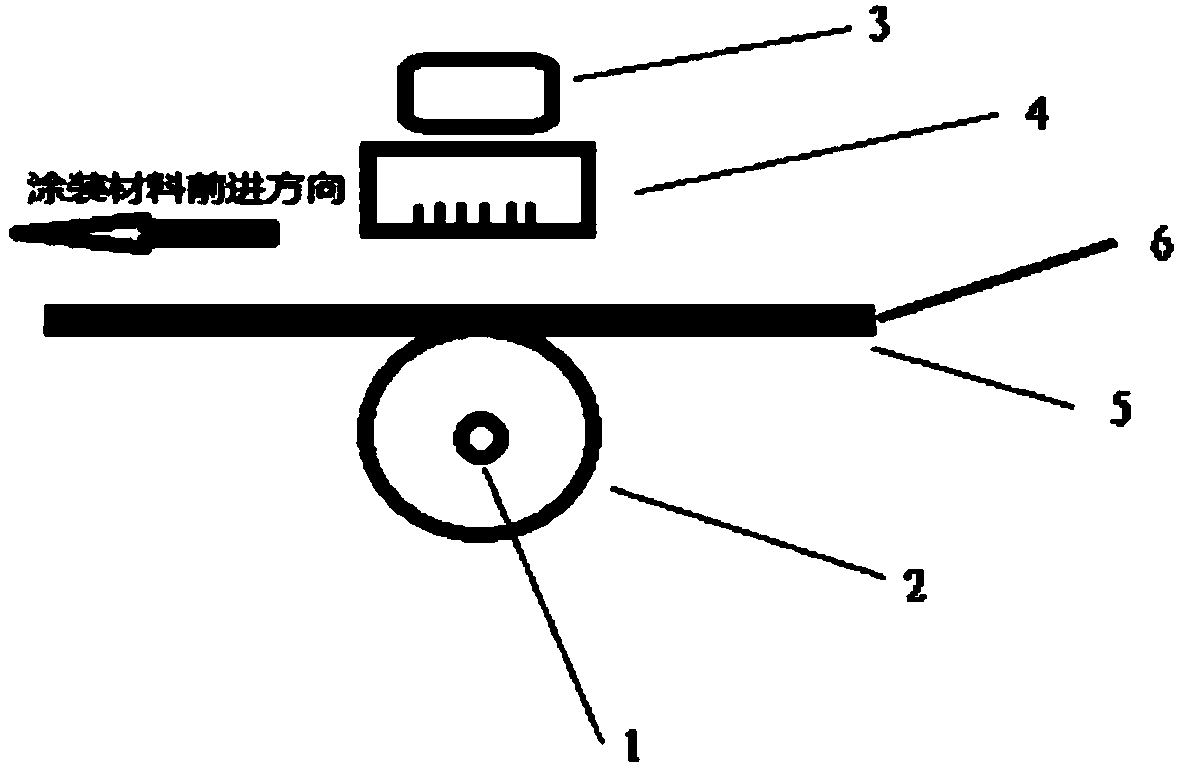

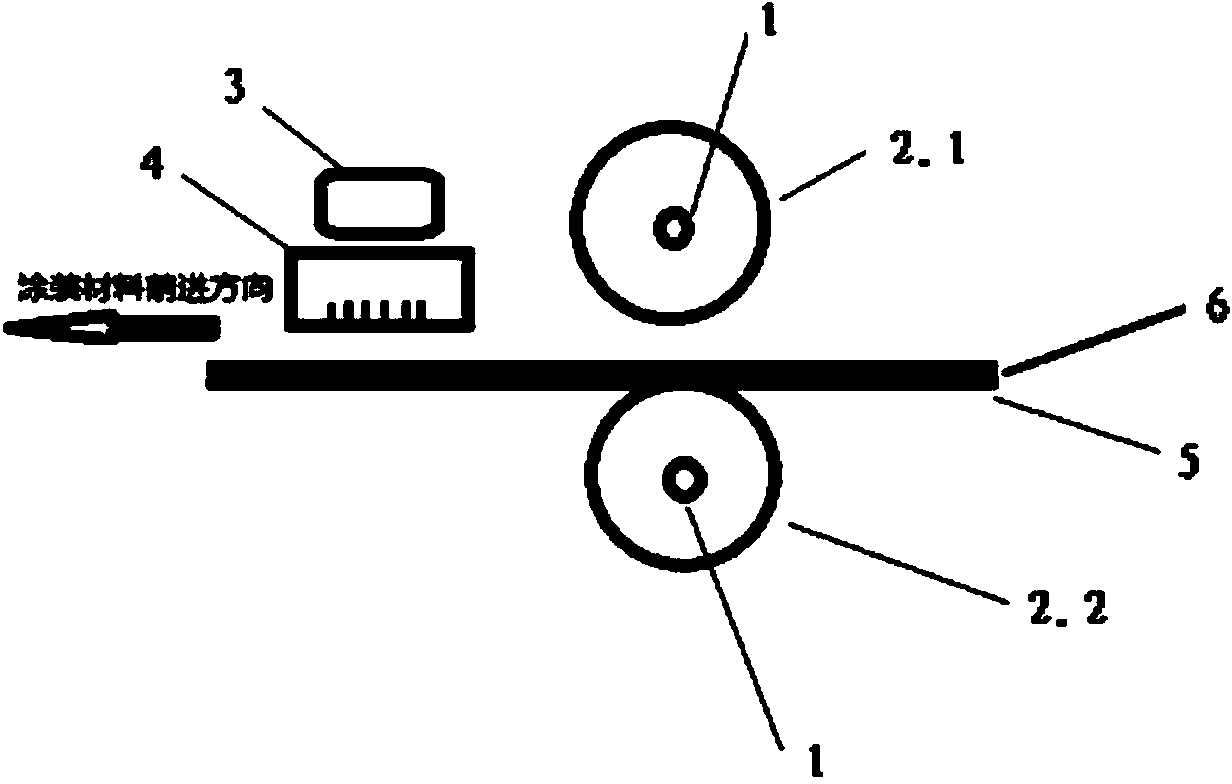

[0044] The present invention provides a kind of coating equipment of magnetic pigment, along the advancing direction of magnetic pigment coating material, successively be provided with the coating device that continuously coats magnetic pigment coating 6 to coating material 5, is used for magnetic pigment coating 6 Magnetic orientation device for magnetic orientation and magnetic setting device for magnetic setting of magnetic pigment paint 6 .

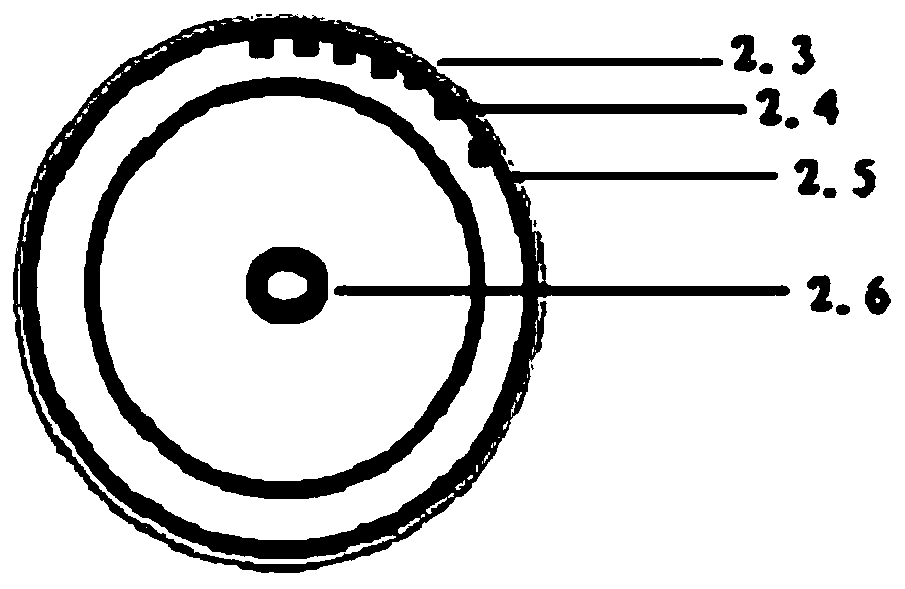

[0045]In the present invention, the magnetic orientation device includes a magnetic mold assembly 2, and the magnetic mold assembly 2 is installed above or / and below the coating material 5, and also includes a magnetic mold assembly bracket 1, a motion motor, a motion bearing shaft system, a control The electromagnetic power input system, the magnetic module 2 can move active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com