Processing method for sweet Tie Guanyin tea

A processing method, the technology of Tieguanyin, is applied in the processing field of Qingtian Tieguanyin tea, which can solve the problems such as the decline of tea grades, slow aftertaste of bitterness and astringency, and achieve the effect of smooth taste, sweet taste and increased sugar conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

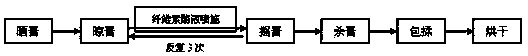

Method used

Image

Examples

Embodiment 1

[0022] The fresh leaves of Tieguanyin are sun-dried according to the traditional process after picking. The tea leaves after drying are placed in the greening room for the first time. The temperature in the room is adjusted to 27°C and the humidity is 85%. Spraying concentration is 1.2wt% cellulase liquid, the mass ratio of enzyme liquid and tealeaves is 1:5, carry out the first shake green after spraying, shake green rotating speed is 6r / min, shake green green time 15min; After the greening is finished, carry out the second drying of the blue, adjust the indoor temperature to be 27°C, the humidity 85%, the drying time of 60min, the tea leaves after drying are sprayed with a cellulase solution with a concentration of 0.8wt%, the quality of the enzyme solution and the tea leaves The ratio is 1:10, after the spraying, shake the green for the second time, the shaking speed is 7r / min, and the shaking time is 20min; %, drying time 120min, the tea leaves after drying are sprayed wit...

Embodiment 2

[0025] The fresh leaves of Tieguanyin are sun-dried according to the traditional process after picking. The tea leaves after drying are placed in the greening room for the first time. The temperature in the room is adjusted to 27°C and the humidity is 85%. Spraying concentration is the cellulose enzyme liquid of 1.2wt%, and the mass ratio of enzyme liquid and tealeaves is 1:6, carries out the first shake green after spraying, and shake green rotating speed is 8r / min, shake green green time 15min; After the greening is finished, carry out the second drying of the blue, adjust the indoor temperature to be 27°C, the humidity 85%, the drying time of 60min, the tea leaves after drying are sprayed with a cellulase solution with a concentration of 0.8wt%, the quality of the enzyme solution and the tea leaves The ratio is 1:12, after the spraying is finished, shake the green for the second time, the speed of shaking is 7r / min, and the shaking time is 20min; %, airing time 120min, the ...

Embodiment 3

[0028] The fresh leaves of Tieguanyin are sun-dried according to the traditional process after picking. The tea leaves after drying are placed in the greening room for the first time. The temperature in the room is adjusted to 27°C and the humidity is 85%. Spraying concentration is 1.2wt% cellulase liquid, the mass ratio of enzyme liquid and tealeaves is 1:5, carry out the first shake green after spraying, shake green rotating speed is 8r / min, shake green green time 15min; After the greening is finished, carry out the second drying of the blue, adjust the indoor temperature to be 27°C, the humidity 85%, the drying time of 60min, the tea leaves after drying are sprayed with a cellulase solution with a concentration of 0.8wt%, the quality of the enzyme solution and the tea leaves The ratio is 1:12, after the spraying is finished, shake the green for the second time, the speed of shaking is 7r / min, and the shaking time is 20min; %, airing time 120min, the tea leaves after drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com