Atomizing device of seed sowing machine

A technology of atomization device and seeder, which is applied in sowing, watering devices, gardening, etc., can solve the problems of low work efficiency, uneven spraying, high labor intensity, etc., and achieve the effect of improving work efficiency and overcoming uneven spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

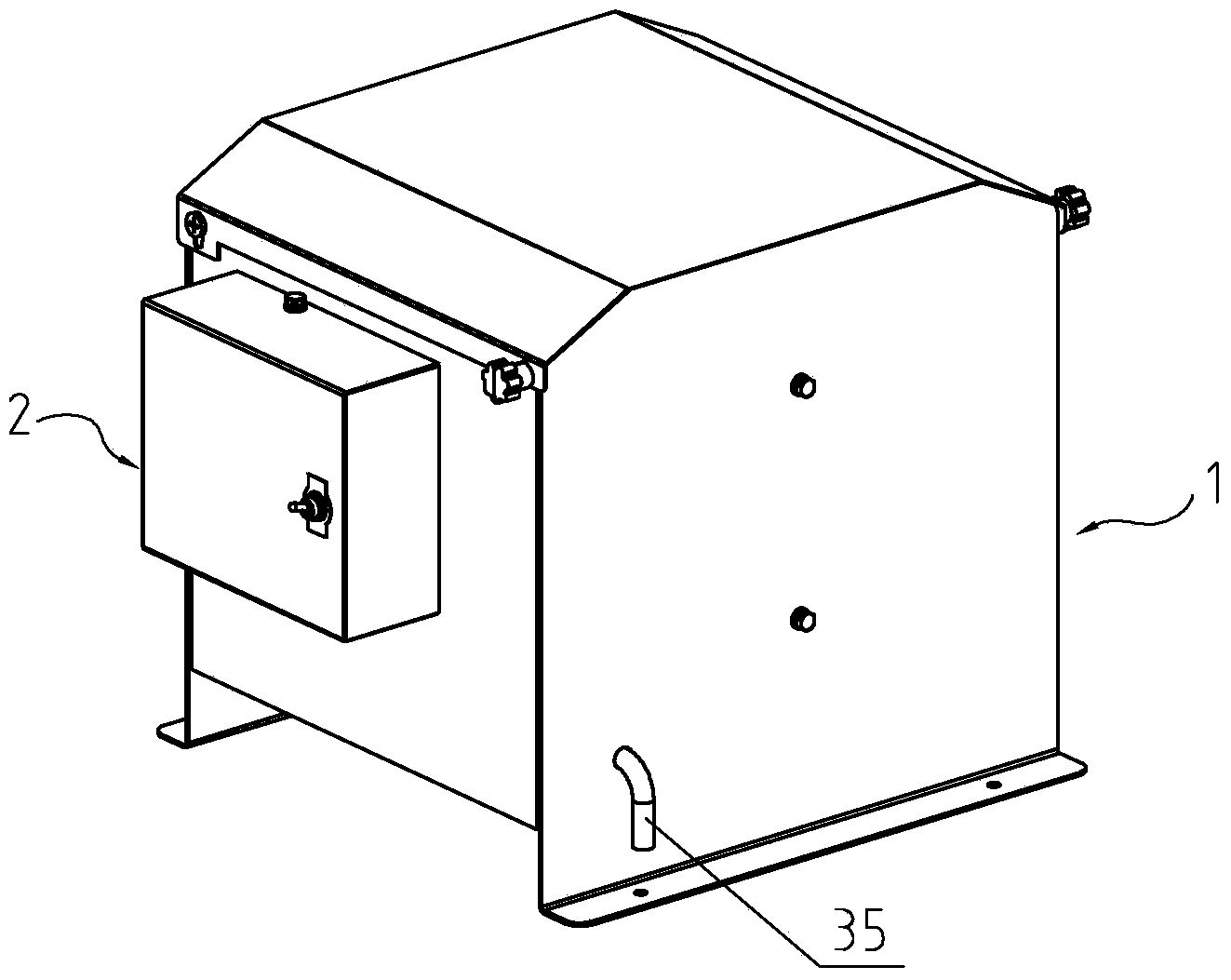

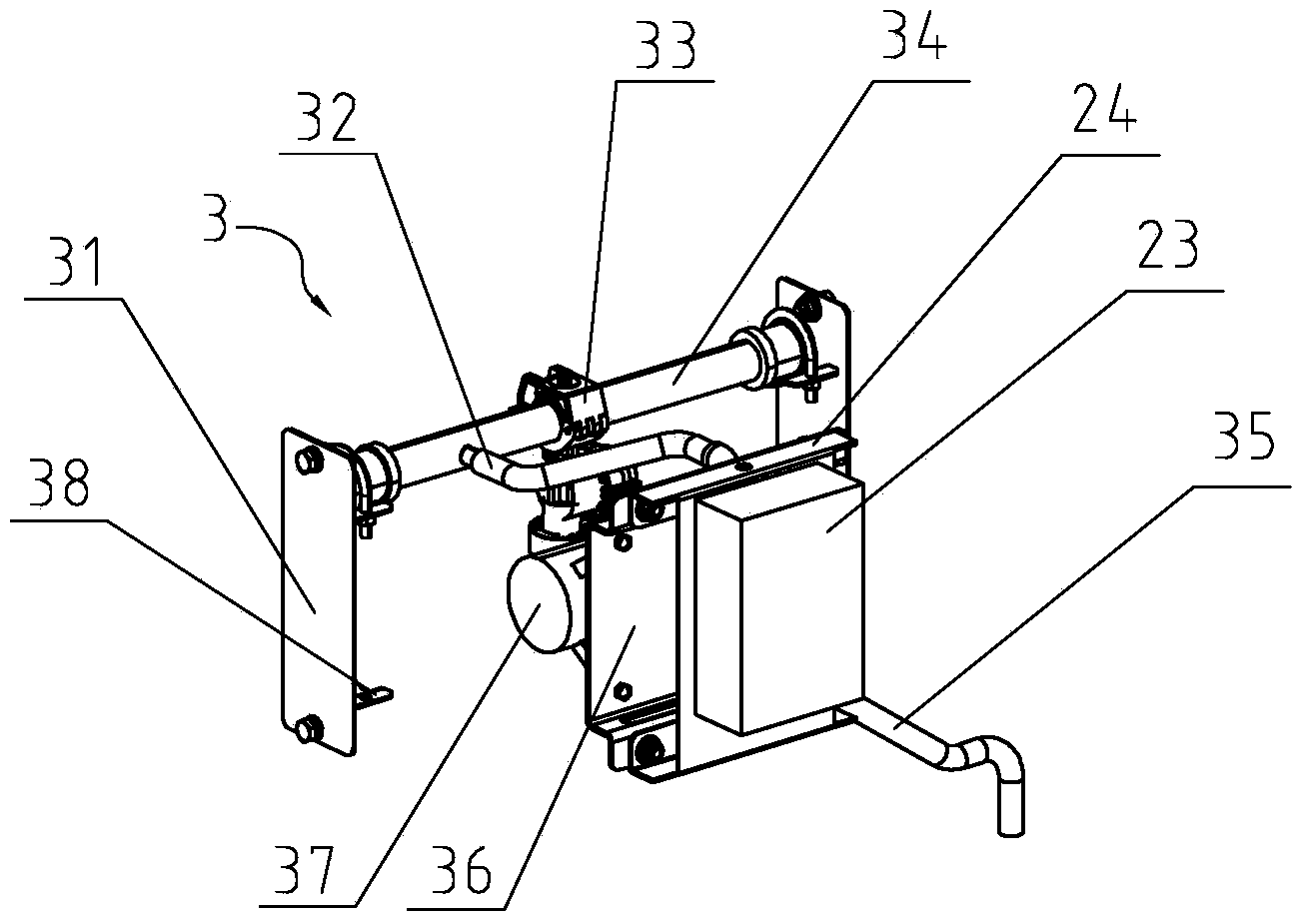

[0014] Such as Figure 1 to Figure 4 As shown, the atomization device of the seeder of the present invention includes an atomization box 1, a spraying device 3 and an electric control device 2, and the atomization box 1 is fixedly connected on two guide rails of the seeder (not shown in the figure) ). The atomization box 1 includes two side plates 11, a cover plate 12 connected to the upper ends of the two side plates 11, and connecting plates 13 respectively connected to the front and rear ends of the two side plates 11, and the bottom ends of the two side plates 11 are perpendicular to the outside. A fixing part 14 connected with the seeder guide rail is provided by bending and extending. Spray device 3 comprises water pump 37, water suction pipe 35, water outlet pipe 32, atomization water pipe 34, atomization nozzle 33 and atomization water pipe 34 positioning devices, water suction pipe 35 one ends are connected with the water inlet of water pump 37, and one end of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com