Method for predicating residual intensity of metal gradient material with cracks

A gradient material and strength prediction technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large cumulative errors and high calculation costs, and achieve the effect of residual strength prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

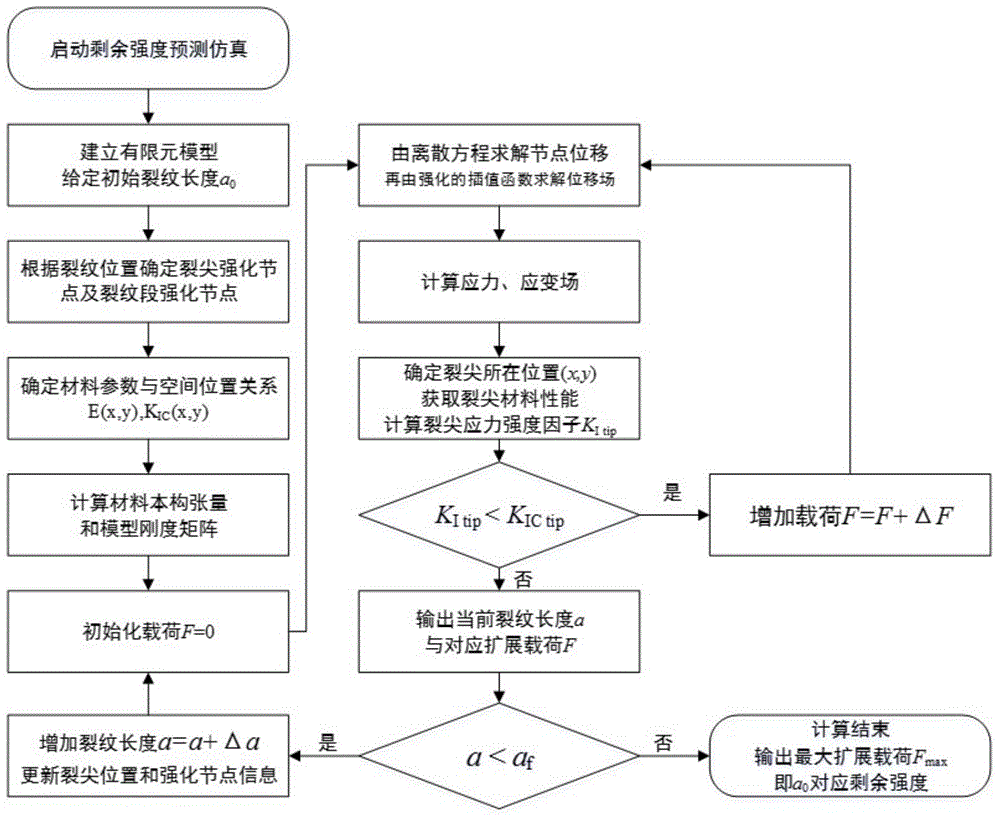

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

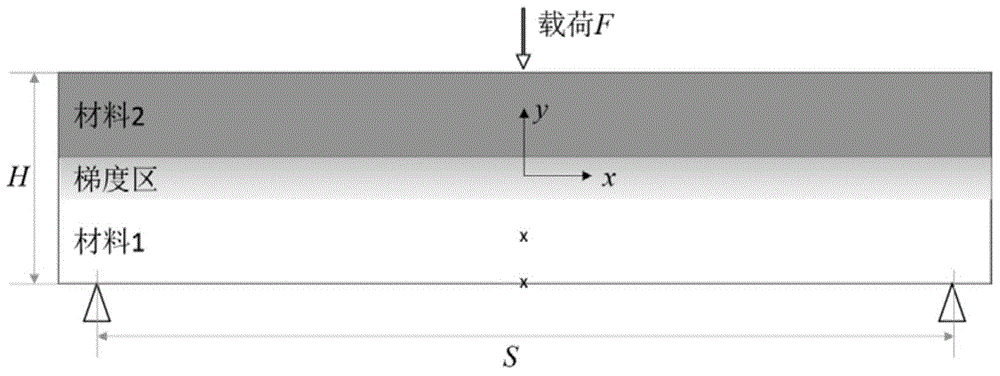

[0081] Step 1. Establish a finite element model such as image 3 , the height of the model is H=24mm, the material gradient area is located at a highly symmetrical place, its thickness is t=1mm, and the span between fulcrums is S=96mm. This embodiment deals with edge cracks, so there is only one crack tip, and the places marked with x are the crack tip and the crack start point respectively, the crack start point is located at the middle point of the lower boundary of the model, and the distance between the crack tip and the start point is the initial crack length a 0 =8.6mm, define the crack termination length a in this embodiment f =15mm.

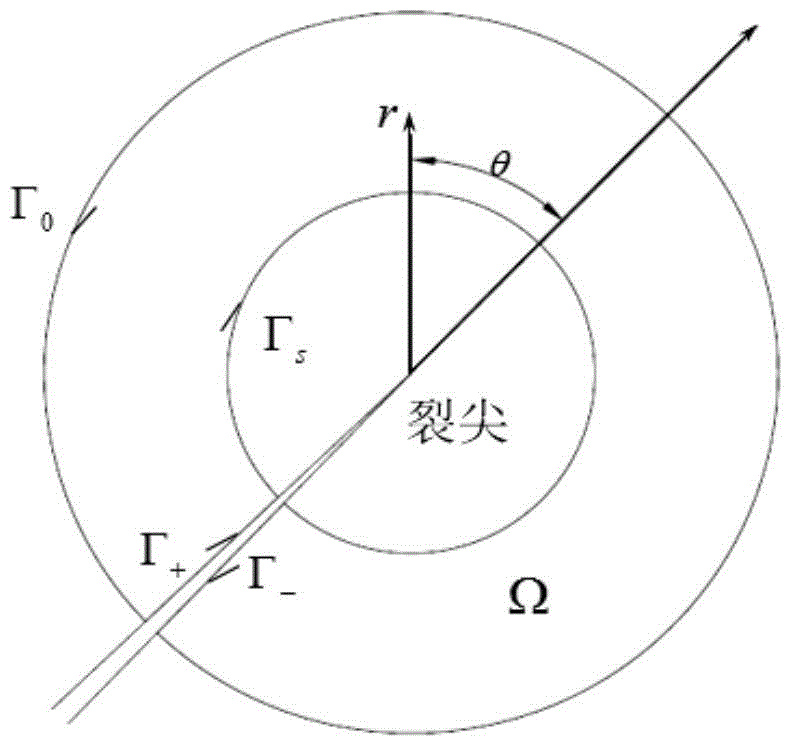

[0082] Step 2. Use rectangular units to discretize the model, the grid side length is 1mm, a total of 2640 units; processing node enhancement information such as Figure 4 , the element nodes related to the crack tip are included in the crack tip strengthening node set N Λ , the element nodes related to the crack segment are included i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com