Single-system computerized flat knitting machine with double-system functions

A computerized flat knitting machine and single-system technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problem that single-system computerized flat knitting machines do not have the same tuck, dual-system computerized flat knitting machines have complex structures, and limited market capacity and other problems, to achieve the effect of small wear, simple structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0057] Example.

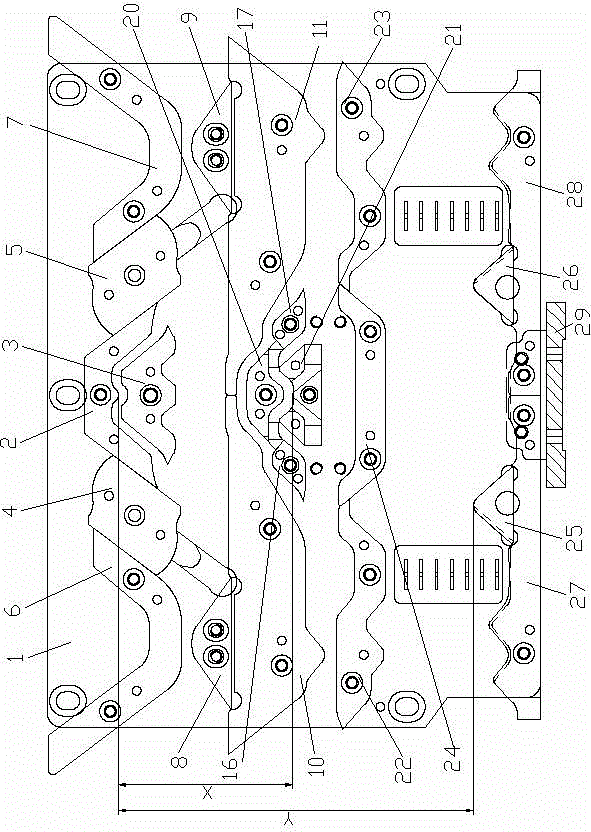

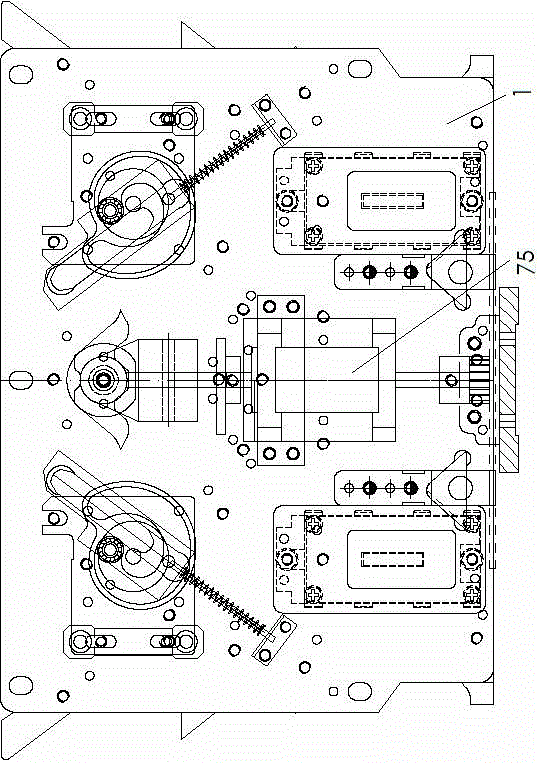

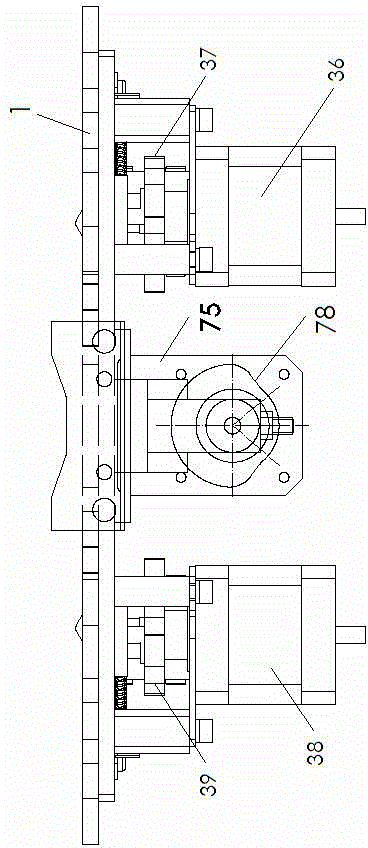

[0058] see Figure 1 to Figure 37 , the single-system computerized flat knitting machine with dual system functions in this embodiment includes a frame 91, a machine base 92, a needle plate 93, a machine head 94, a large bar 95 and a display screen 96, wherein the machine base 92 is usually a cast iron machine base , the frame 92 is fixed on the frame 91, and the needle plate 93 is fixed on the frame 92, each piece before and after, the knitting needle 81, the spring stitch 82 and the needle selection pin 83 slide up and down in the needle groove of the needle plate 93. The large bar 95 is installed on the machine base 92, the machine head 94 and the display screen 96 are all installed on the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com