Cloth cutting device of textile machine

A cutting device and textile machine technology, applied in thin material processing, transportation and packaging, winding strips, etc., can solve the problems of uneven cloth incisions, cloth incisions hairy, affecting the quality of cloth rolls, etc., to improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

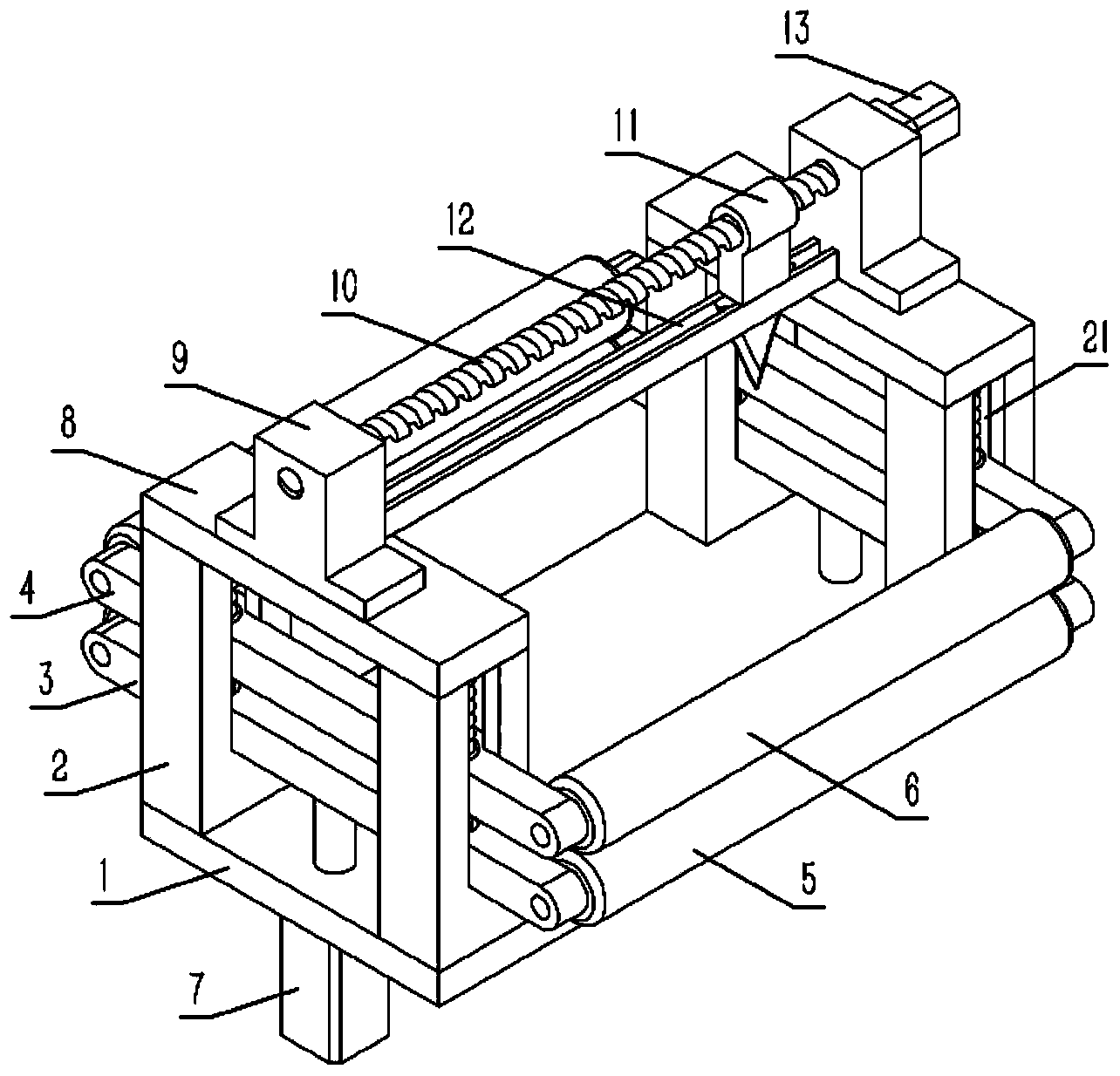

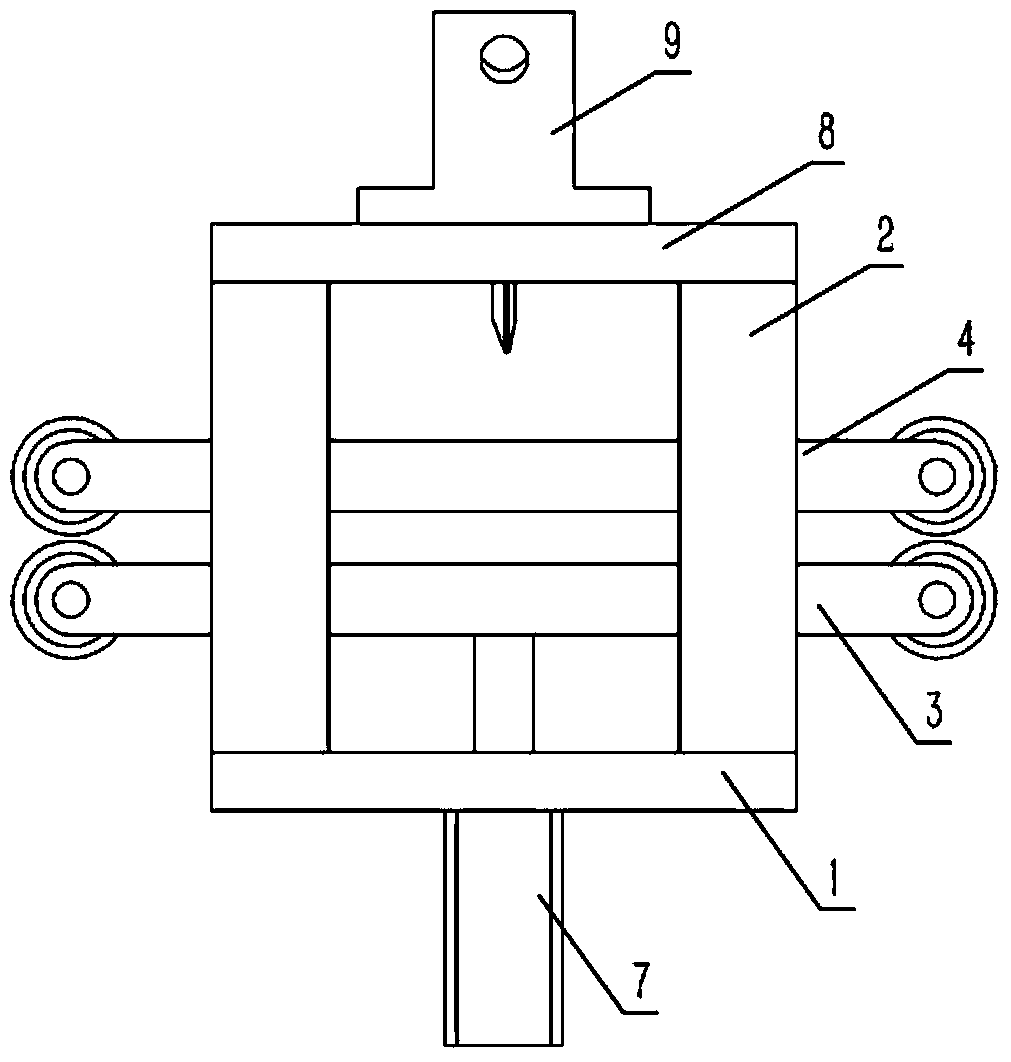

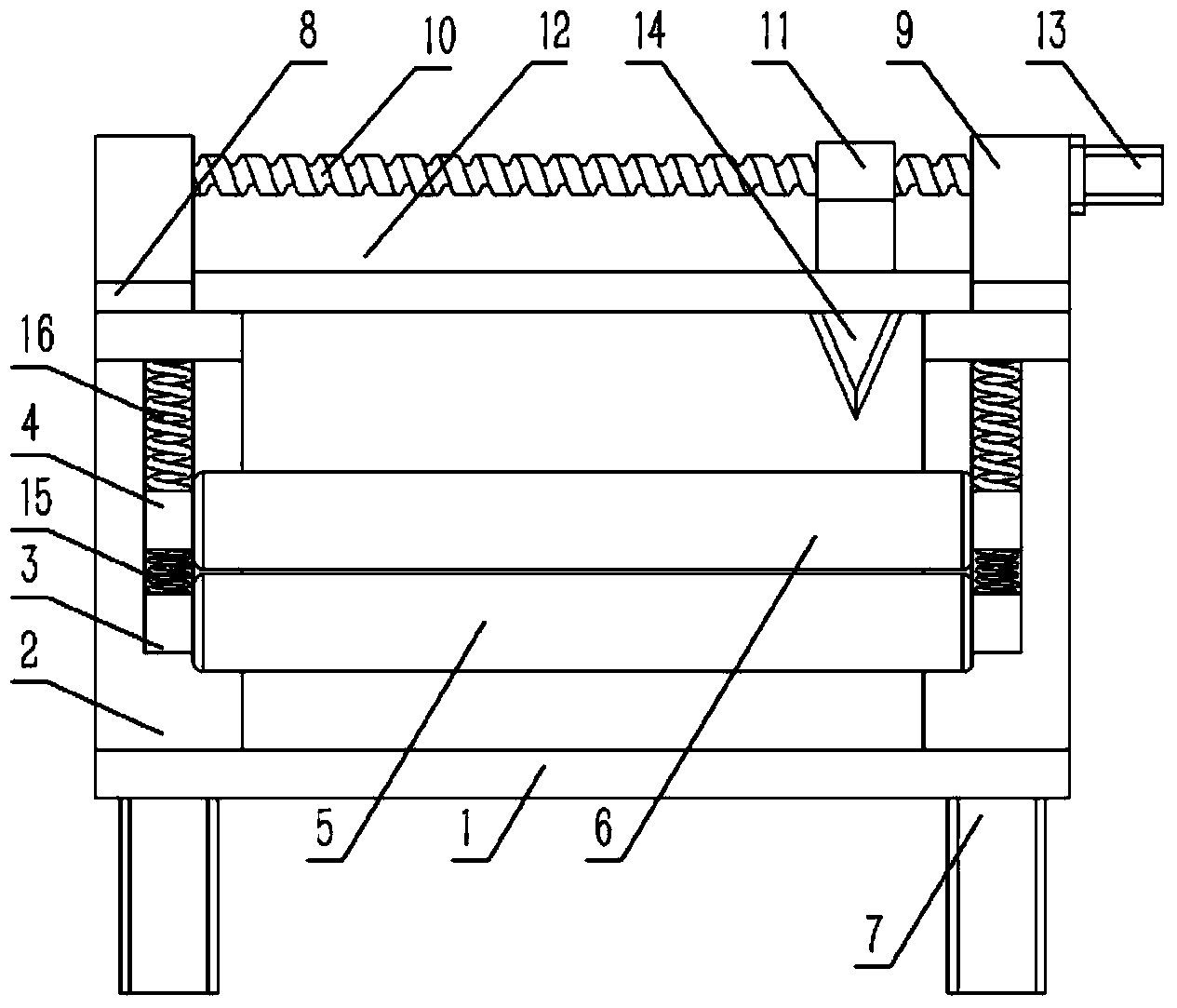

[0018] Example: see Figures 1 to 4 As shown, a textile machine cloth cutting device includes a base plate 1, four columns 2 are fixed on the base plate 1, and the four columns 2 are distributed on the front and rear sides of the base plate 1, and the columns 2 on the front and rear sides of the base plate 1 are all A crossbeam 8 is fixed, a lower connecting rod 3 and an upper connecting rod 4 are sleeved on the uprights 2 on the front and rear sides of the bottom plate 1, the two ends of the lower connecting rod 3 are respectively hinged with the lower guide roller 5, and the two ends of the upper connecting rod 4 The upper guide rollers 6 are respectively hinged, and a compression spring 15 is arranged between the upper connecting rod 4 and the lower connecting rod 3. The two ends of the compression spring 15 are respectively pressed against the upper connecting rod 4 and the lower connecting rod 3. The bottom plate A cylinder 7 is fixed on the lower end surface of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com