Storage rack device capable of storing and transmitting rolled materials

A material and roll-type technology, applied in the field of roll-type material storage and transmission devices, can solve the problems of customer dissatisfaction, inconvenience in viewing and selection of roll-type materials, low operation efficiency, etc., so as to reduce labor costs and labor intensity. , Reduce the effect of conveying operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

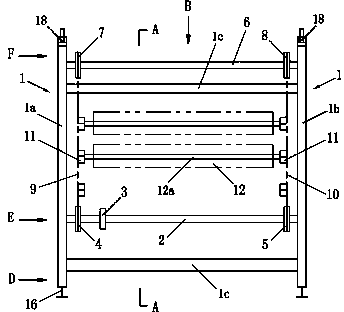

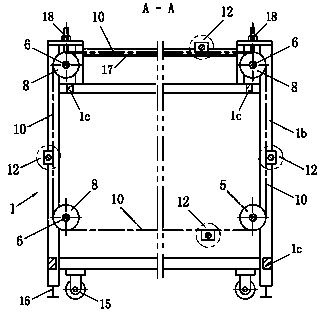

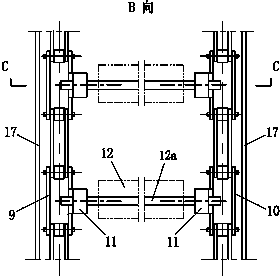

[0033] A bracket 1 is provided, and the bracket 1 includes a first side frame 1a and a second side frame 1b respectively located on both sides, see figure 1 ; A number of connecting rods 1c are provided between the first side frame 1a and the second side frame 1b to form a frame-like overall structure of the bracket 1 .

[0034] Provided with drive shaft 2, see figure 1 , both ends of the drive shaft 2 are respectively connected to the first side frame 1a and the second side frame 1b; Image 6 It shows a structural form in which one end of the transmission shaft 2 is connected to the first side frame 1a, that is, the connection between the shaft end of the transmission shaft 2 and the first side frame 1a is realized through the bearing support 1d, and the other end of the transmission shaft 2 is connected to the second side frame 1b's connection structure with Image 6 The same as shown; the connection structure between the two ends of the transmission shaft 2 and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com