Screw locking suction nozzle mechanism

A technology of screw locking and screwing, which is applied to screwdrivers, wrenches, manufacturing tools, etc. It can solve the problems of fixed suction nozzle height, inability to adjust, and shaking screwdriver head, so as to improve the locking accuracy, prevent the bit from swinging, and function Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

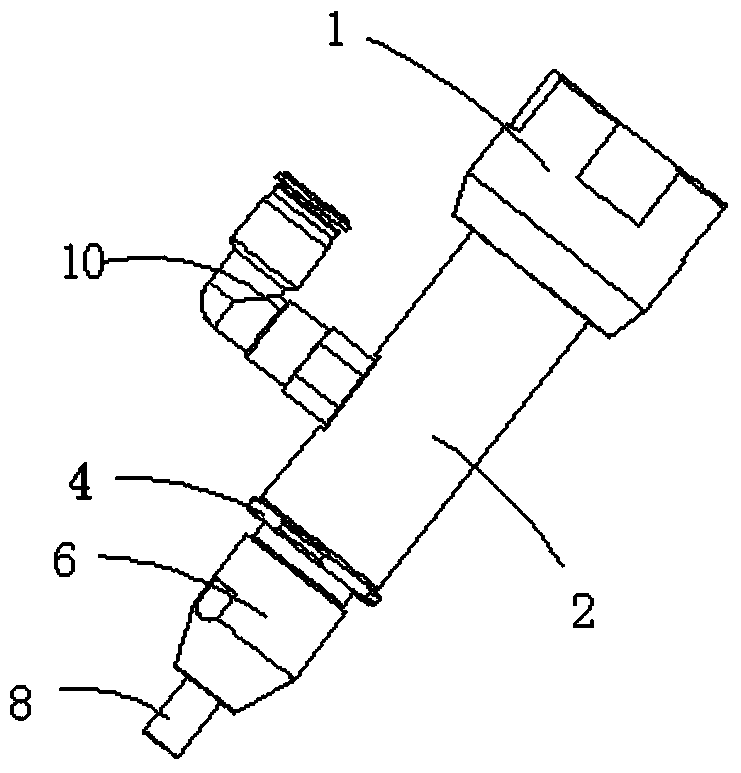

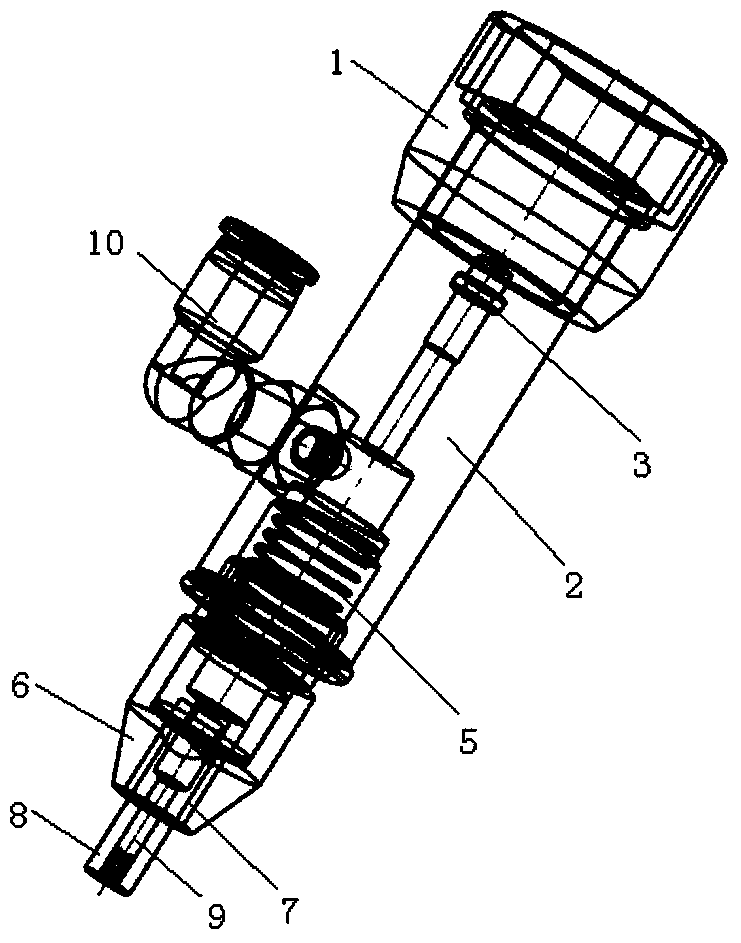

[0014] Examples, see attached figure 1 and 2 , a screw-locking suction nozzle mechanism, which includes butt screw 1, vacuum sleeve 2, sealing ring 3, adjustable nut 4, spring 5, front screw head 6, oil-free bushing 7, suction nozzle 8 and a screwdriver Head 9, the upper end of the vacuum sleeve is connected with the butt screw, and the upper part of the vacuum sleeve is closed by a sealing ring; the front screw is assembled in the vacuum sleeve, and the upper and lower positions of the front screw are adjusted through an adjustable nut, so that Adjust the up and down position of the suction nozzle, and the vacuum sleeve is equipped with a spring; the front head screw is equipped with an oil-free bushing, the suction nozzle is installed on the front head screw, and the suction nozzle is guided by the oil-free bushing to improve Locking precision; the screwdriver head passes through the vacuum sleeve and the spring inside it to the position of the suction nozzle.

[0015] A g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com