Stepping switch with vacuum switching tubes

A technology of vacuum switching and tap changer, applied in electrical switches, high-voltage/high-current switches, inductors, etc., which can solve the problems of large size determination, increased power consumption, and electrical uncertainty of power transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

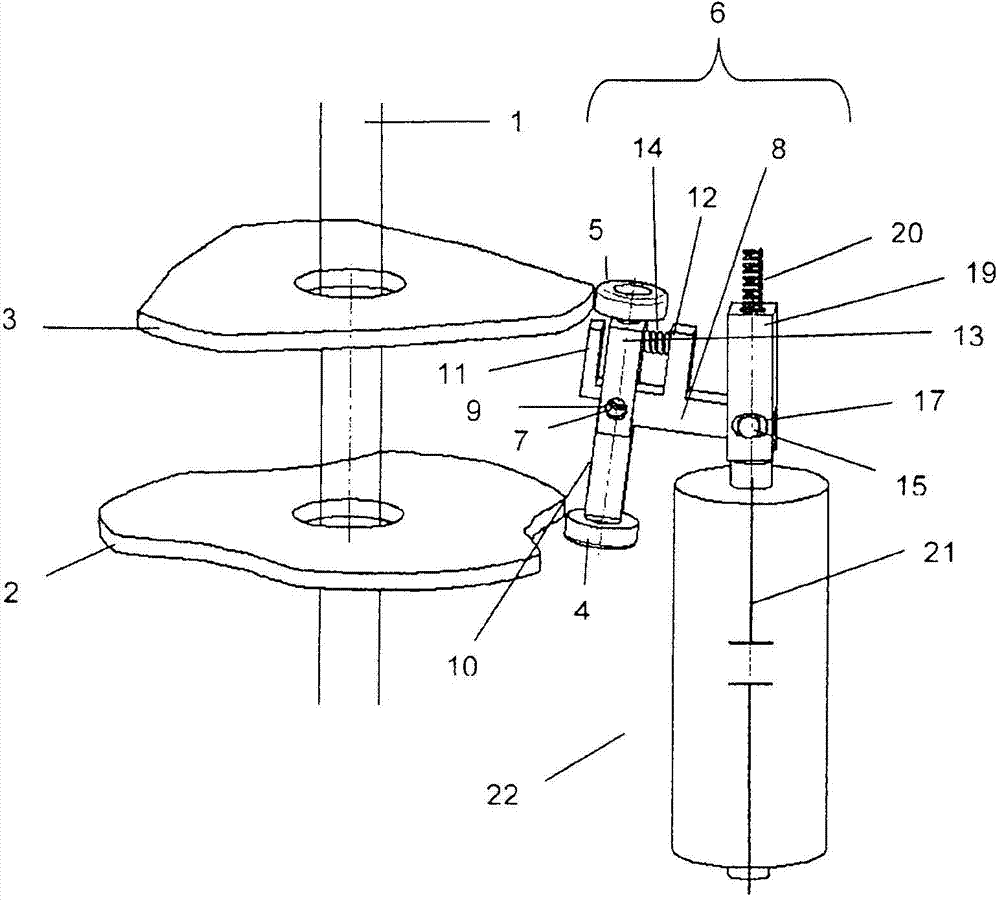

[0018] For clarity reasons, below in figure 1 Only those components of the tap changer with vacuum switching tube according to the invention which are relevant to the invention are shown and described in the diagram. Descriptions and illustrations of features known per se and components not relevant to the essence of the invention are omitted. Correspondingly, figure 1 A switching shaft 1 is shown, which is driven by a likewise not shown spring accumulator and on which two parallel, spaced apart, off-circular cam disks 2 and 3 are arranged in a non-rotatable manner. Namely a first cam disc 2 and a second cam disc 3 . The surrounding contours of the two cam disks 2 and 3 are arranged on the shifting shaft 1 substantially star-shaped in the illustrated embodiment, but pointing oppositely by 180°. The number of cam disks used and their surrounding contour depend on the switching sequence on which the tap-changer is based and the vacuum switching tubes required for this per pha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap