Sample blank manufacturing device and method for anchor or pile and soil interface friction performance test

A technology for making devices and interfaces, applied in the field of bolt or pile foundation testing, can solve problems such as failure to truly reflect the friction performance of the anchor-soil or pile-soil interface, lack of sealing and water-retaining devices, and poor repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

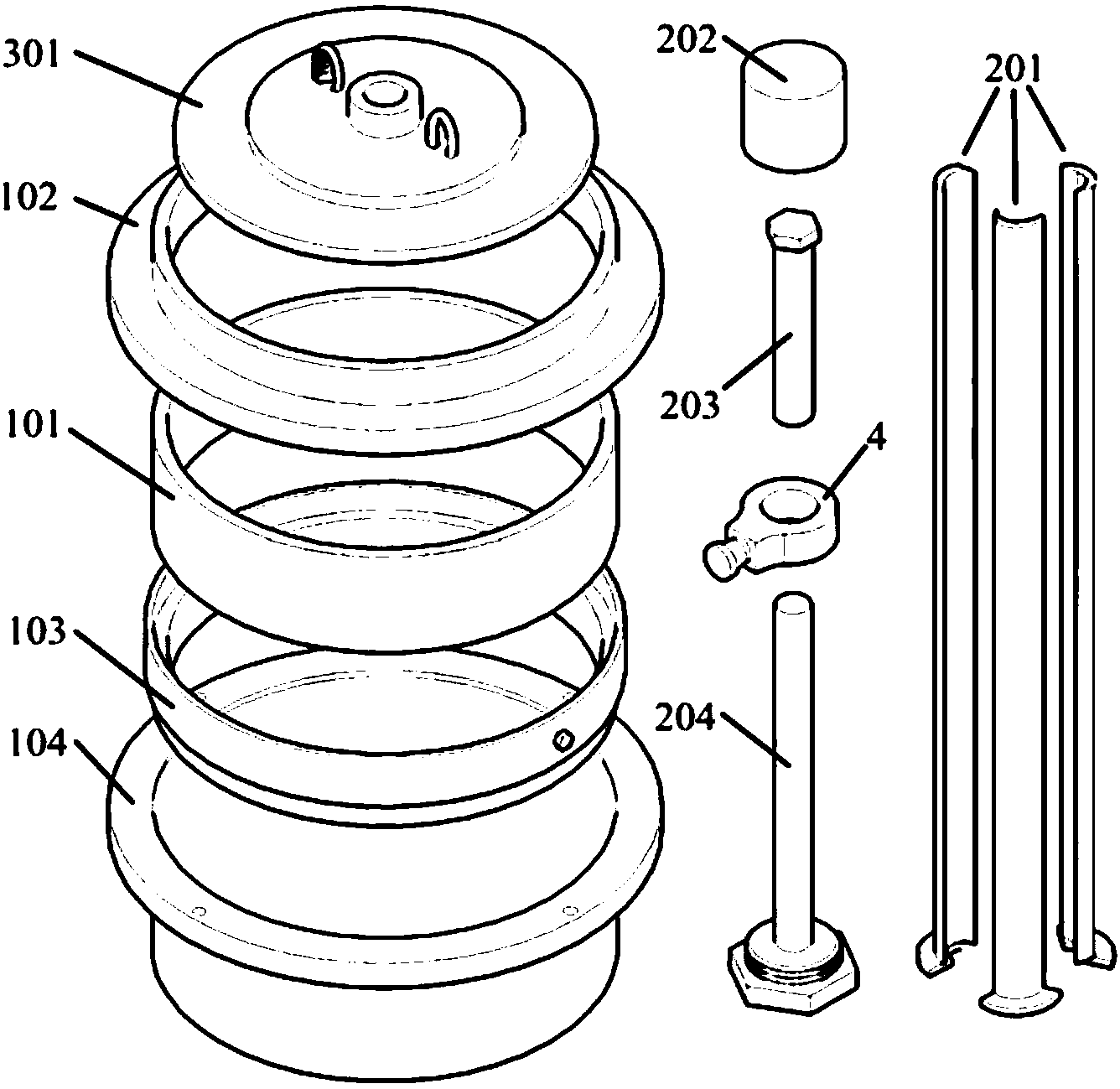

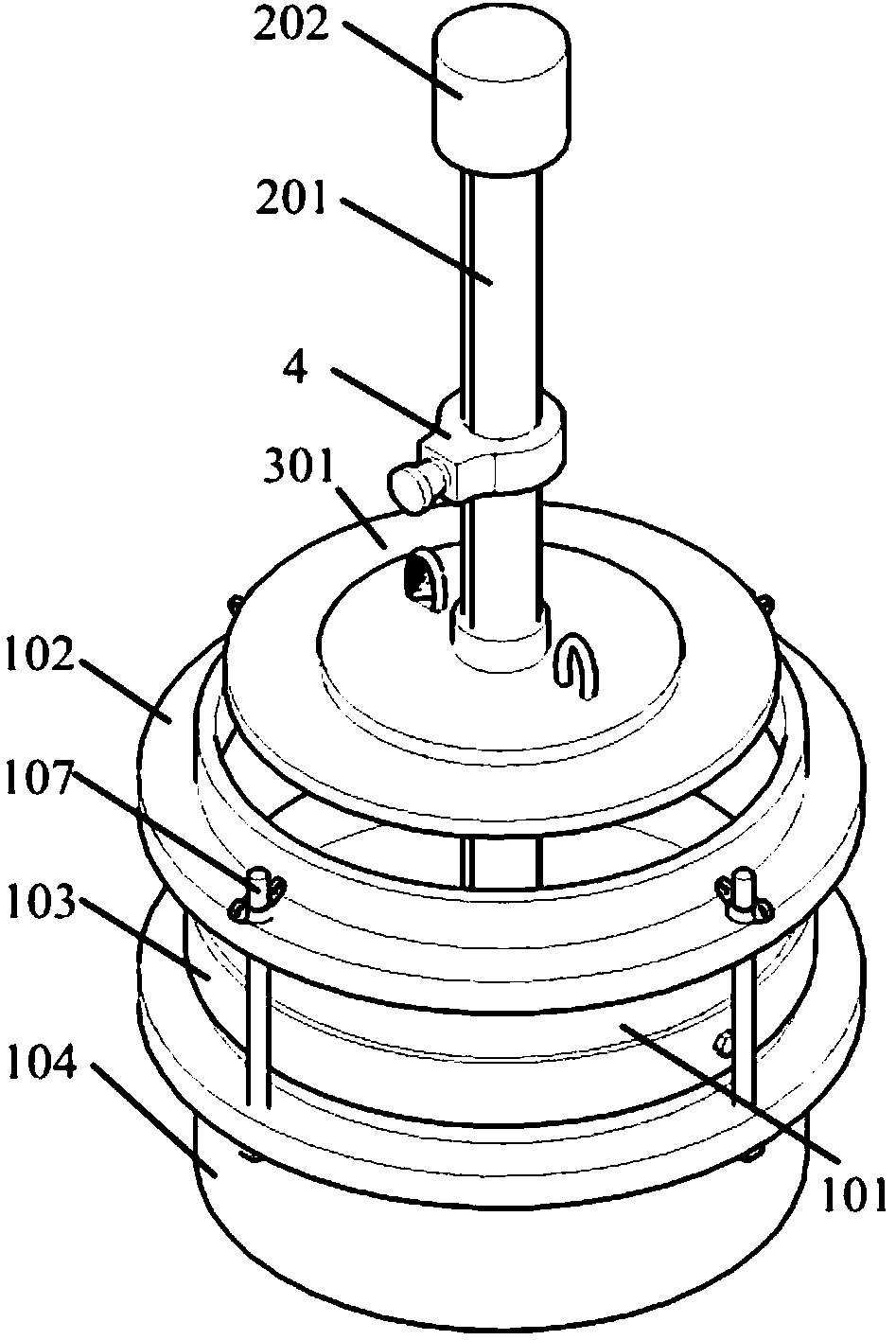

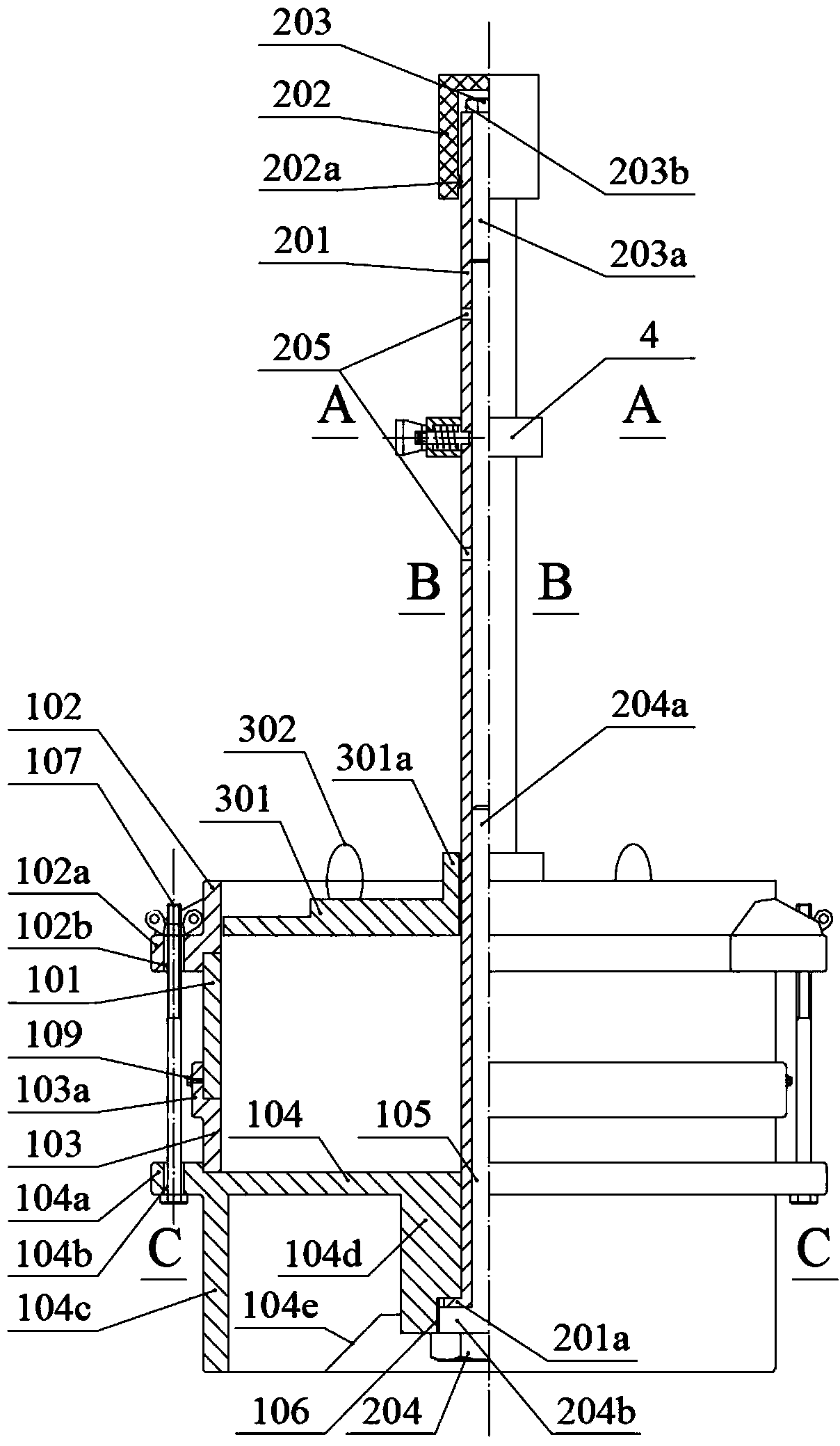

[0047] Such as Figure 1-7 As shown, a kind of sample making device and method for anchor or pile and soil interface friction performance test are as follows:

[0048] (1) plexiglass material is made, and wall thickness 1cm, internal diameter is 30cm, and height is respectively 4cm, 10cm, 4cm heightening cylinder 102, sample cylinder 101 and pad cylinder 103 utilize the inner groove of the outer edge 102a of heightening cylinder 102 and The inner grooves of the upper protrusions 103a of the cushion cylinder 103 are sequentially fitted, the specific way is that the upper end of the sample cylinder 101 is embedded in the inner groove of the outer edge 102a of the heightening cylinder 102, and the lower end is embedded in the inner groove of the upper protrusion 103a of the gasket cylinder 103, The lower end of the washer 103 is embedded in the inner groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com