Spherical prism sleeve base for measuring center coordinates of round hole

A technology of central coordinates and prisms, which is applied in the field of housings for ball prisms, can solve the problems of low accuracy and time-consuming, etc., and achieve the effects of improving measurement accuracy, accurate positioning, and convenient installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

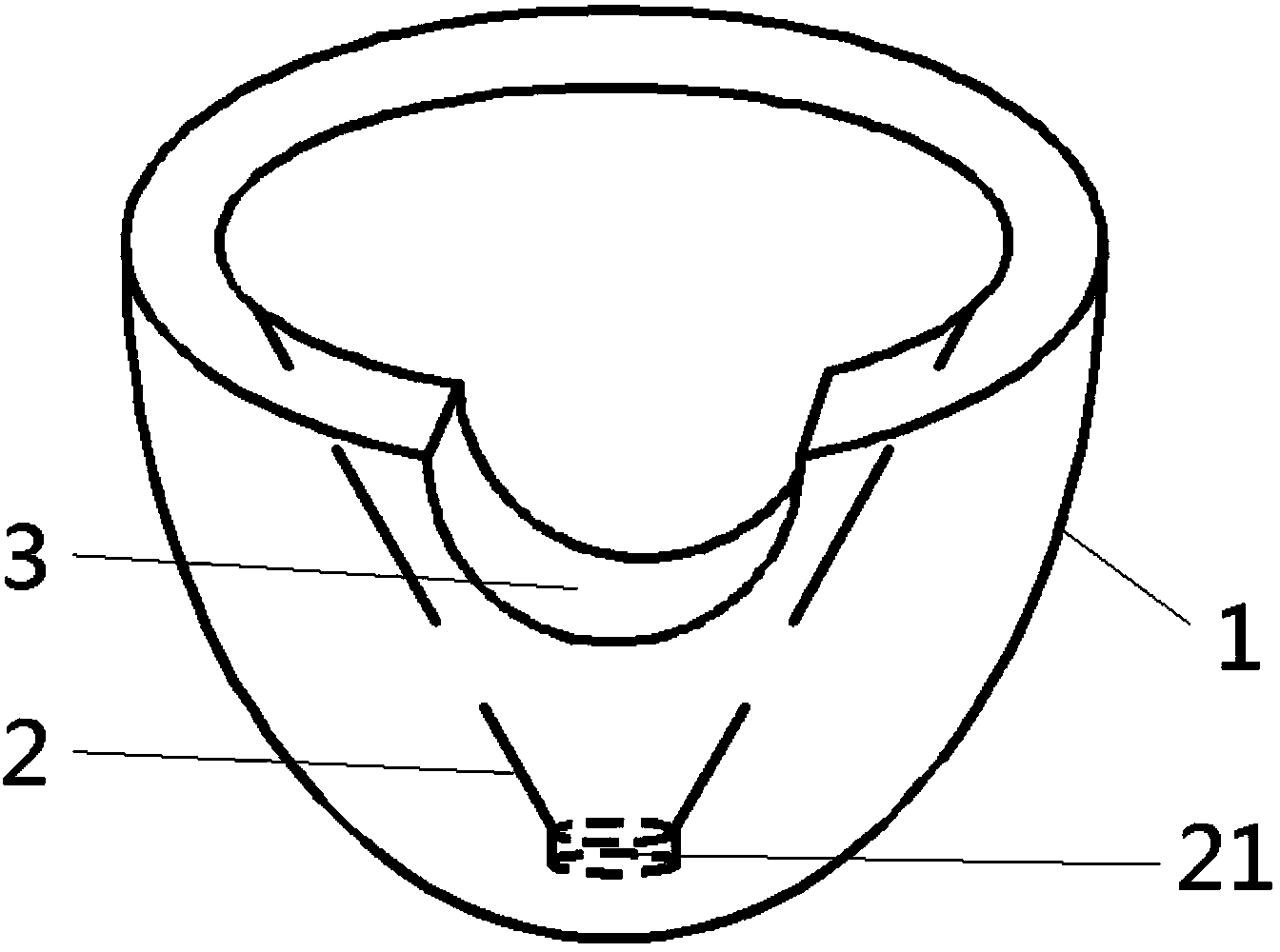

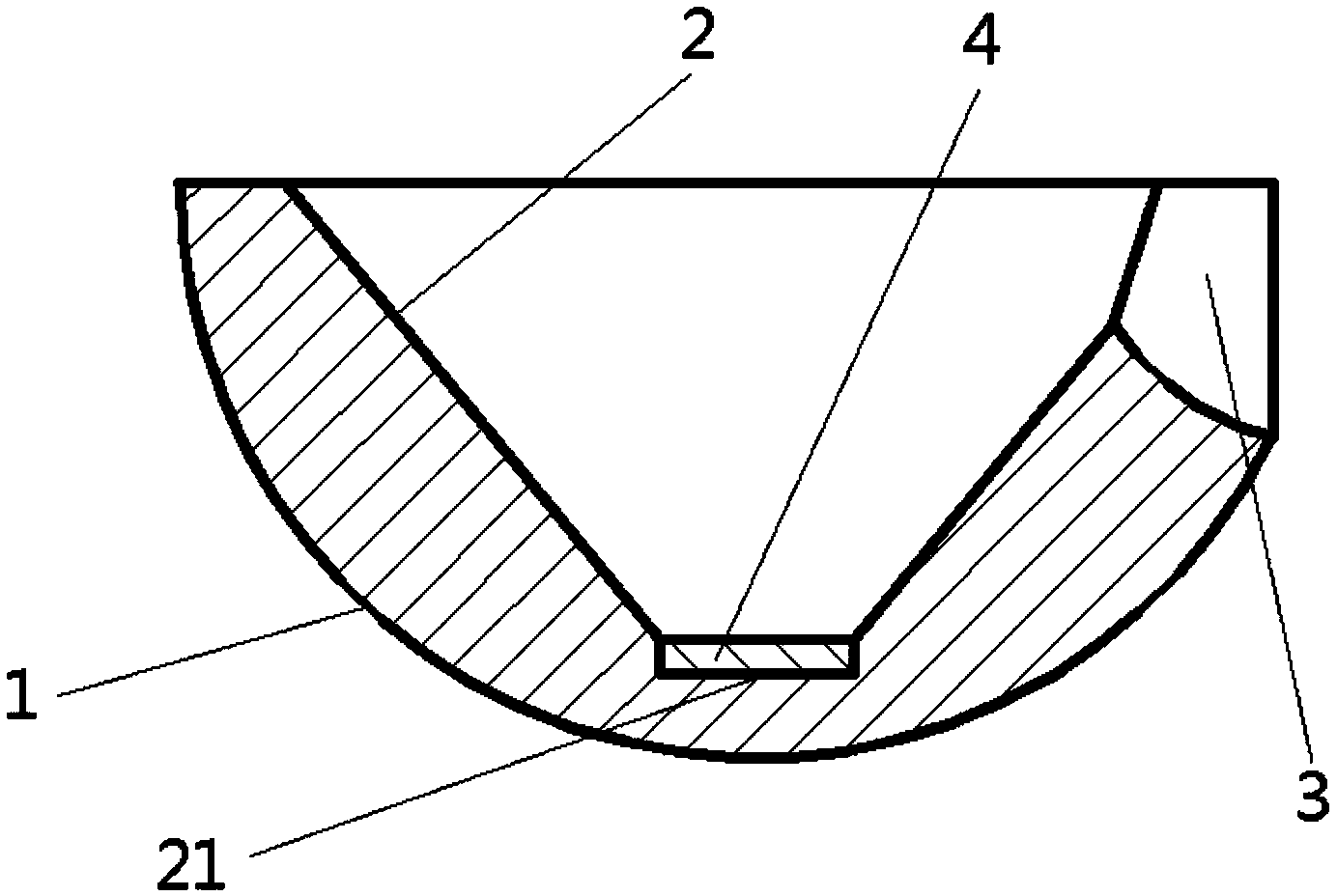

[0017] Such as figure 1 As shown, a ball prism socket for measuring the central coordinates of a circular hole, the spherical prism socket for measuring the central coordinates of a circular hole is a concave structure, and the opening is located at the upper end of the concave structure. The shape of the outer surface 1 of this sleeve seat is hemispherical, and the shape of the inner surface 2 of this sleeve seat is a conical shape with the tip of the cone facing down, so that the ball prism 5 (such as image 3 Shown) the center of the sphere coincides with the central axis of the conical shape of the inner surface 2, and the cone angle of the conical shape is preferably 90°. At this time, the contact between the outer surface of the ball prism 5 and the inner surface 2 of the sleeve seat The area is the largest, so that the spherical prism 5 can be more stably seated in the sleeve to obtain accurate measurement results; the central axis of the conical shape of the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com