A kind of fertilizer that can be used for seed fertilizer simultaneous sowing and its production method

A fertilizer and trace element fertilizer technology, applied in fertilizer mixtures, applications, fertilization devices, etc., can solve the problems of long slow release period, nutrient waste, etc., and achieve improved nutrient utilization rate, slow nutrient release, and obvious economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

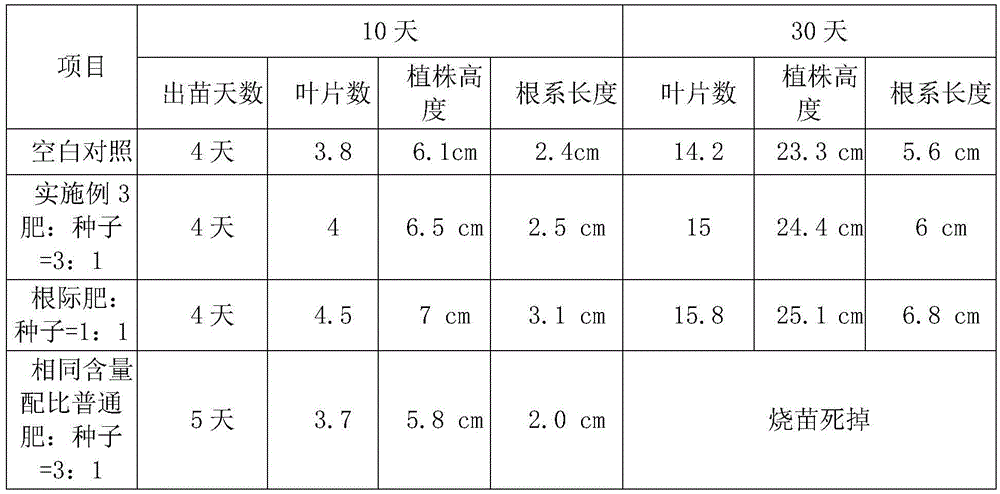

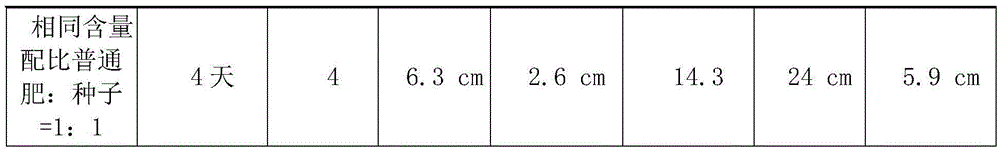

Examples

Embodiment 1

[0026] Phosphate rock with a mass of 1750 kg is crushed by a crusher and then enters a ball mill to be ground into a pulp. The pulp is sent to the extraction tank to react with 1250 kg of concentrated sulfuric acid with a mass concentration of 98% to obtain a phosphoric acid slurry. The phosphoric acid slurry is vacuum filtered Dilute phosphoric acid with a mass concentration of 22% is obtained; concentrated phosphoric acid with a mass concentration of 43% is obtained after the dilute phosphoric acid is concentrated in a vacuum. After the concentrated phosphoric acid is settled by the material method, 200 kg of the concentrated phosphoric acid is taken and transported by a centrifugal pump to the tail gas cleaning liquid sealing tank of the finished product production workshop. neutralize. The washing liquid is transported to the neutralization reaction tank through a centrifugal pump, and reacts with 300 kg of urea in the neutralization tank to make a slurry. Add 150 kg of po...

Embodiment 2

[0028]Phosphate rock with a mass of 1725 kg is crushed by a crusher and then enters a ball mill to be ground into a pulp. The pulp is sent to the extraction tank to react with 1200 kg of concentrated sulfuric acid with a mass concentration of 98% to obtain a phosphoric acid slurry. The phosphoric acid slurry is vacuum filtered Dilute phosphoric acid with a mass concentration of 21% was obtained; concentrated phosphoric acid with a mass concentration of 41% was obtained after the dilute phosphoric acid was concentrated in a vacuum. After the concentrated phosphoric acid is settled by the material method, 150 kg of the concentrated phosphoric acid is taken and transported by a centrifugal pump to the tail gas cleaning liquid sealing tank of the finished product production workshop. neutralize. The washing liquid is transported to the neutralization reaction tank through a centrifugal pump, and reacts with 250 kg of ammonia water in the neutralization tank to make a slurry. Add 2...

Embodiment 3

[0030] Phosphate rock with a mass of 1700 kg is crushed by a crusher and then enters a ball mill to be ground into a pulp. The pulp is sent to the extraction tank to react with 1200 kg of concentrated sulfuric acid with a mass concentration of 98% to obtain a phosphoric acid slurry. The phosphoric acid slurry is vacuum filtered Dilute phosphoric acid with a mass concentration of 20% is obtained; concentrated phosphoric acid with a mass concentration of 40% is obtained after the dilute phosphoric acid is concentrated in a vacuum. After the concentrated phosphoric acid is settled by the material method, 180 kg of the concentrated phosphoric acid is taken and transported by a centrifugal pump to the tail gas cleaning liquid sealing tank of the finished product production workshop. neutralize. The washing liquid is transported to the neutralization reaction tank through a centrifugal pump, and reacts with 200 kg of ammonia water in the neutralization tank to make a slurry. Add 180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com