Boxing machine

A cartoning machine and cartoning technology, which is applied in packaging, packaging bottles, transportation and packaging, etc., can solve the problems of vial pollution, hidden safety hazards, slow speed, etc., and achieve the goal of reducing mutual scraping, orderly arrangement, and avoiding pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

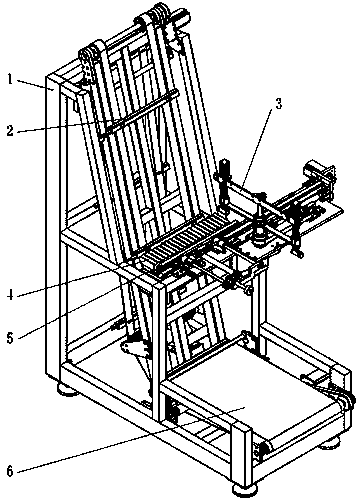

[0022] Such as figure 1 As shown, a cartoning machine of the present invention includes a frame 1, a box supporting mechanism 2, a bottle moving mechanism 3, a bottle discharging mechanism 4, a bottle pushing mechanism 5, and a box transporting mechanism 6. The tray mechanism 2 is installed on the frame 1 at an inclined angle. The bottle-moving mechanism 3 is installed on the frame 1, the bottle-discharging mechanism 4 is installed on the frame 1, the bottle-pushing mechanism 5 is installed on the frame 1, and the box transport mechanism 6 is installed on the frame 1.

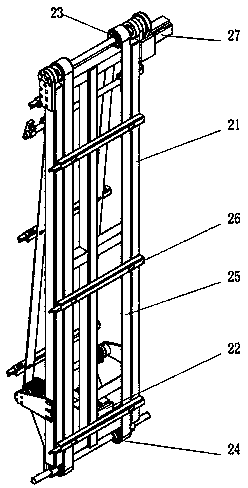

[0023] Such as figure 2 As shown, the box holder mechanism 2 includes a box holder frame 21, a box push cylinder 22, a first driving pulley 23, a first driven pulley 24, a first synchronous belt 25, a horizontal support 26 and a box holder motor 27. Cylinder 22 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com