An auxiliary welding device for tailor-welding hemispherical shells from equally divided melon petals

An auxiliary welding and hemisphere technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unqualified quality of the hemisphere and deformation of N equal parts, so as to solve the problem of low welding efficiency. , easy operation, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

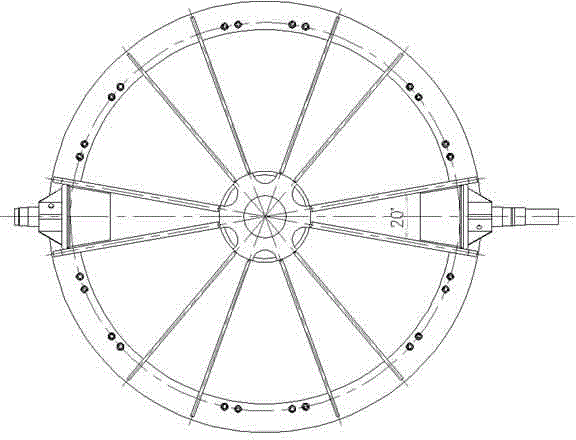

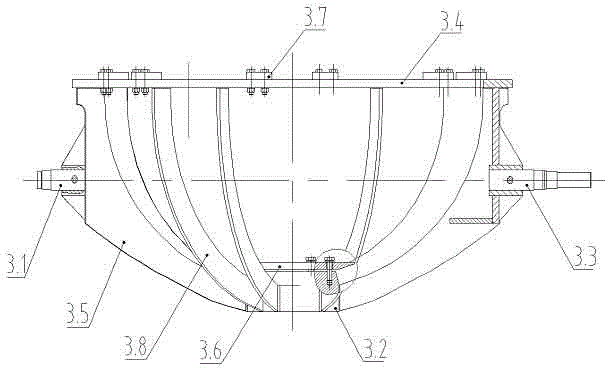

[0021] The present invention is an auxiliary welding device for tailor-welding hemispherical shells from equally divided melon petals. The outer diameter of the hemispherical shell is set as D, and the hemispherical shell can be divided into N equally divided melon petals with equal structure and volume. body, N≥4 and a positive integer.

[0022] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

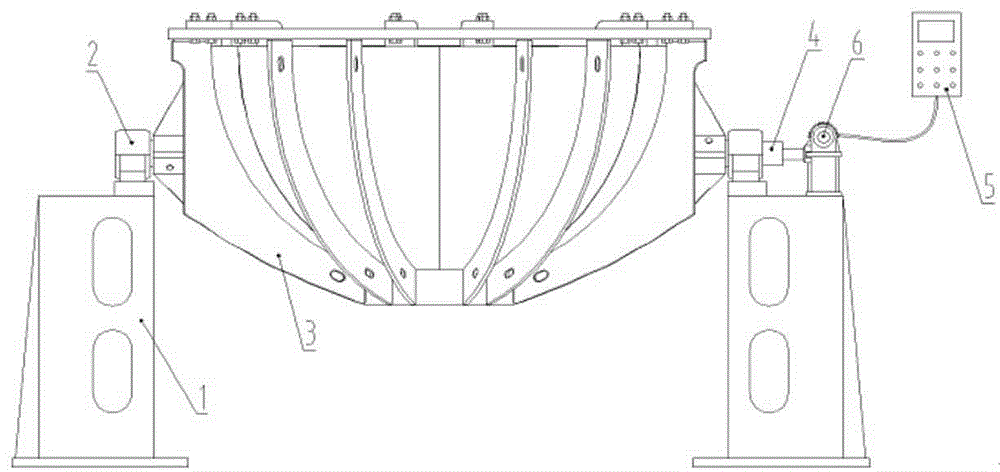

[0023] Under the above conditions and combined with figure 1 , the auxiliary welding device includes bracket 1, bearing seat 2, coupling 4, operation panel 5, reducer and motor 6, the operation panel 5 realizes the forward rotation, reverse rotation and parking of the motor through circuit control, and the motor is connected to the input end of the reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com