Double-layer wafer transfer cavity

A cavity and double-layer technology, which is applied in the field of double-layer film transfer cavity structure, can solve the problems of complicated maintenance and increase equipment use cost, and achieve the effect of reducing equipment use cost, reasonable structure and easy overall equipment maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

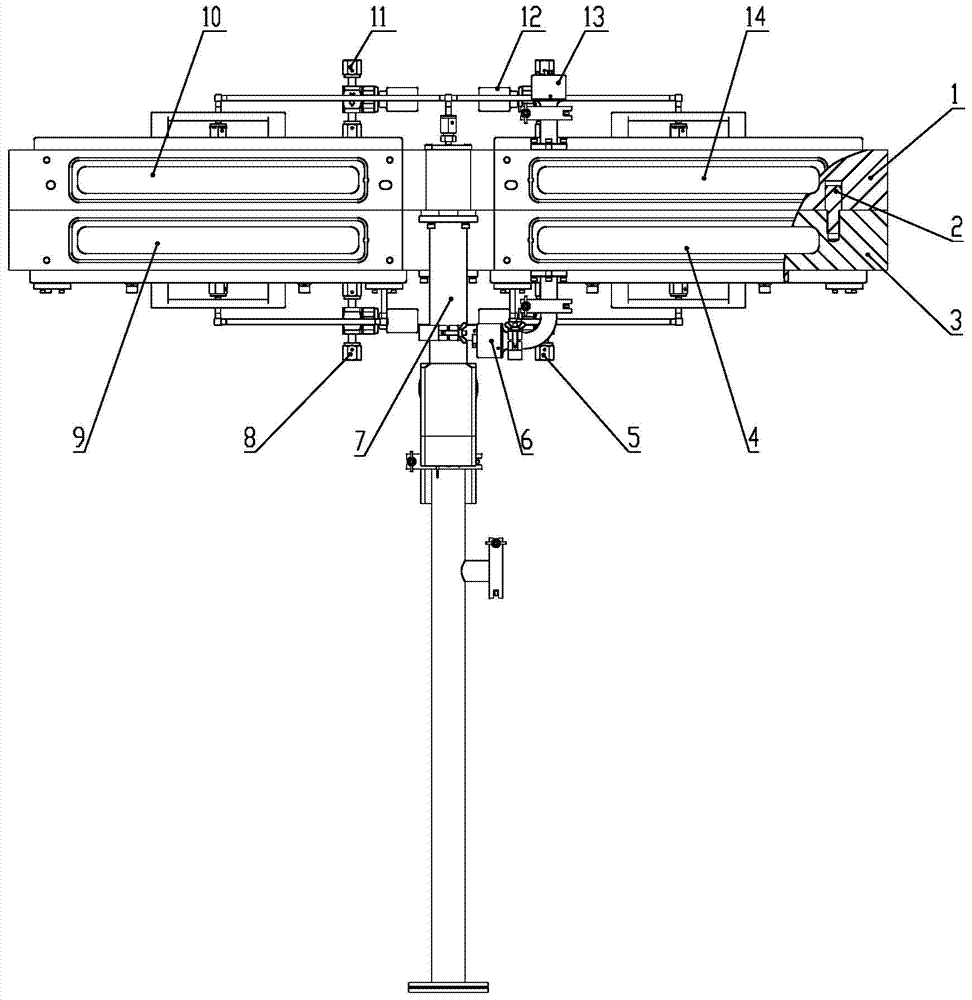

[0012] refer to figure 1 , double-layer film transfer chamber, including upper chamber 1, positioning pin 2, lower chamber 3, chamber A4, chamber B9, chamber C10 and chamber D14, exhaust pipeline 7, vacuum measurement component A6 and vacuum Measuring component B13 and valve body A5, valve body B8, valve body C11 and valve body D12 of balanced atmosphere. The above-mentioned double-layer film transfer cavity is composed of an upper layer cavity 1 and a lower layer cavity 3 , and is fixed by pins 2 . The double-layer chambers have independent pumping pipelines 7, vacuum measurement components A6 and vacuum measurement components B13. The upper and lower chambers can independently complete the film transfer function, and can be used for both single-layer film transfer and double-layer film transfer.

[0013] The above cavities all have two interconnected chambers, the upper chamber 1 is composed of chamber C10 and chamber D14; the lower chamber 3 is composed of chamber A4 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com