A double-cone high-consistency refiner

A high-consistency refiner and double-cone technology, applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc., can solve the problems of inconvenient installation and maintenance, inconvenient maintenance, complex structure, etc. Ease of replacement and maintenance, reduced no-load power consumption, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings; the present embodiments are descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

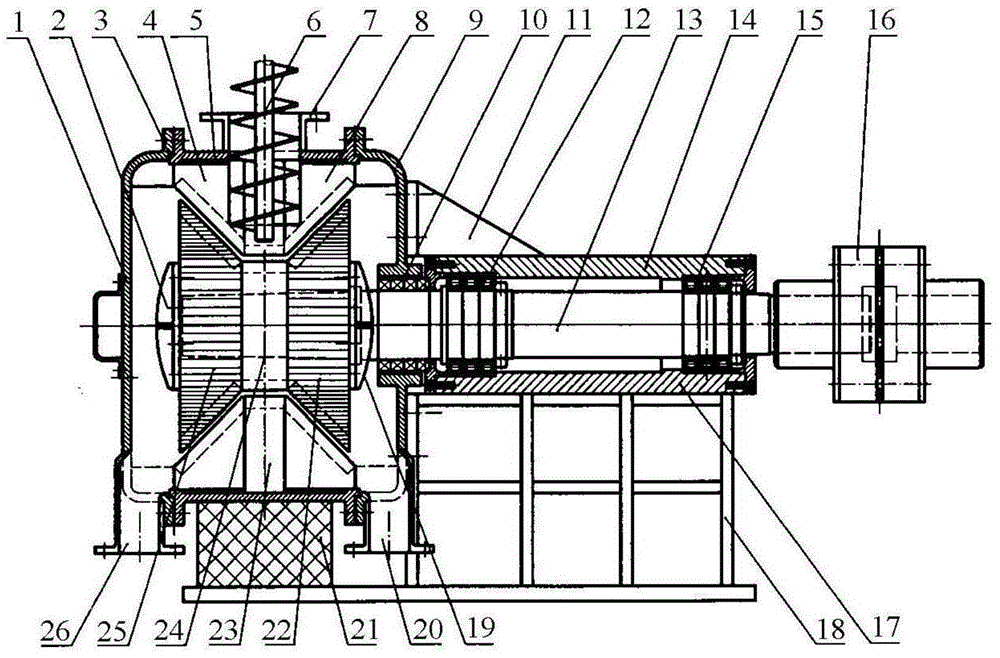

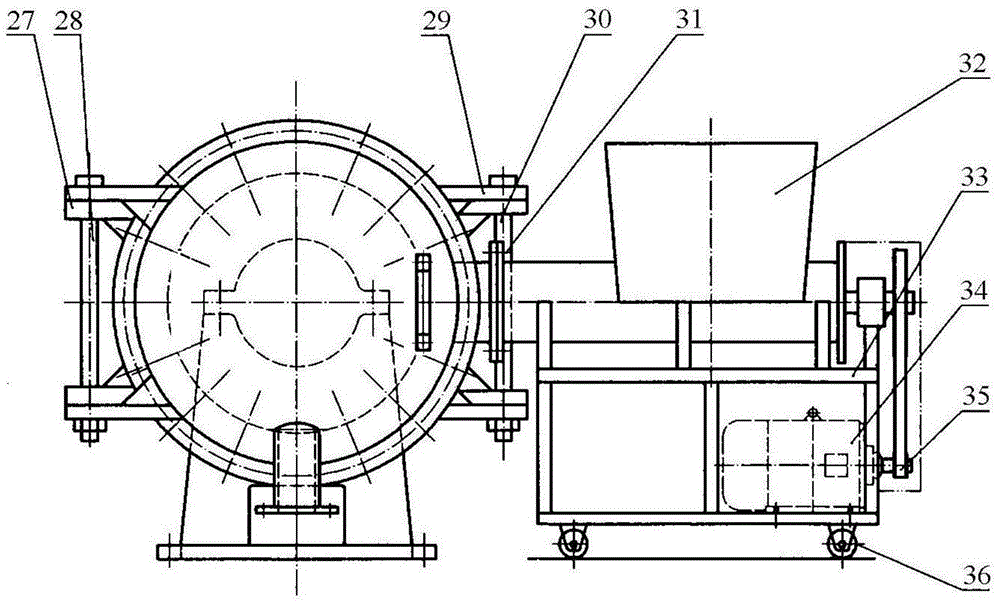

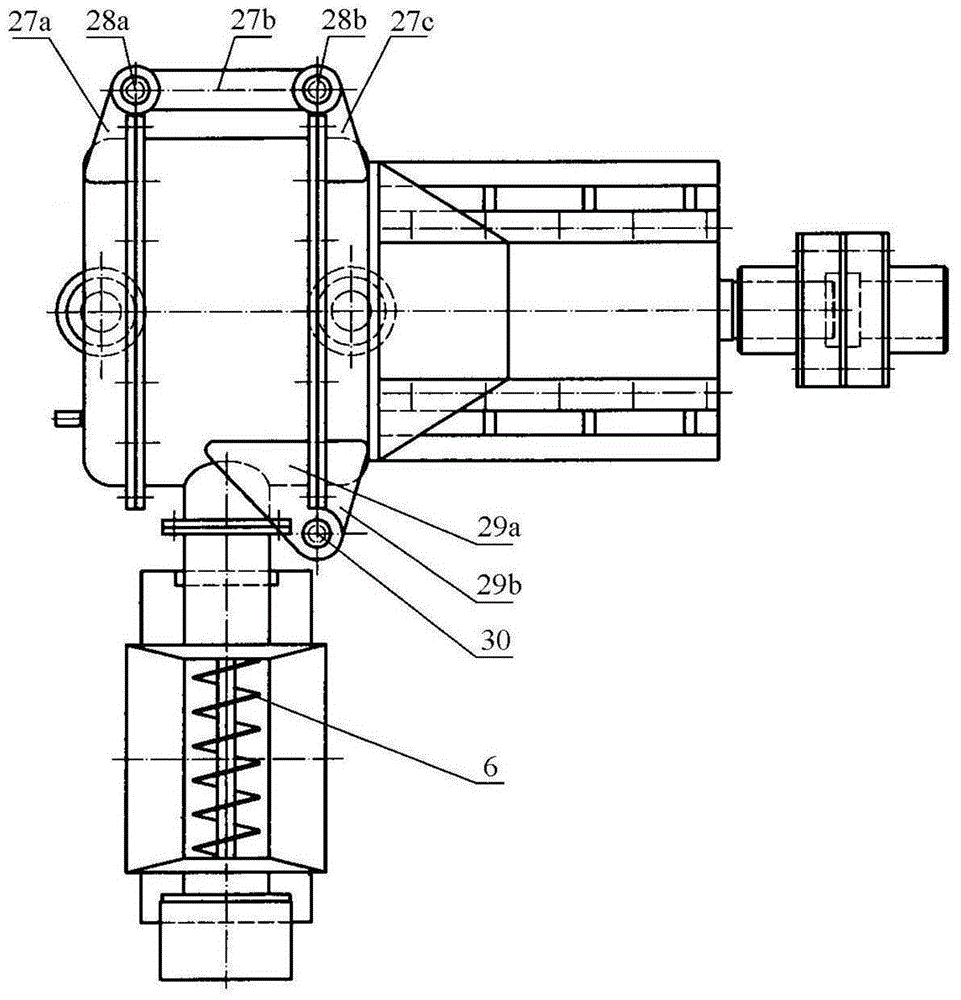

[0024] A double-cone high-consistency refiner, including a frame 18, a main shaft 13, a mill seat 9, a middle part of the mill 5, and a mill cover 1, which is fixed horizontally on the frame by a bearing seat upper cover 14 and a bearing seat The bearing seat that lower seat 17 forms, in this bearing seat coaxially passes front bearing group 12 and rear bearing group 15 to install main shaft (as figure 1 ), the front and rear bearing groups adopt cylindrical roller bearings, which allow the main shaft to move left and right along the axial direction when the main shaft is subjected to axial load; Prevent the slurry from leaking from the connection between the milling chamber seat and the main shaft, and also prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com