Broadband noise reduction porous-material acoustic liner and equipment

A porous material and acoustic lining technology, applied in the field of noise reduction, can solve the problems of high-frequency sound absorption limitation, insufficient mechanical properties of support structures, poor mechanical properties of porous materials, etc., and achieve stable broadband noise reduction and noise reduction performance, excellent noise reduction performance, The effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

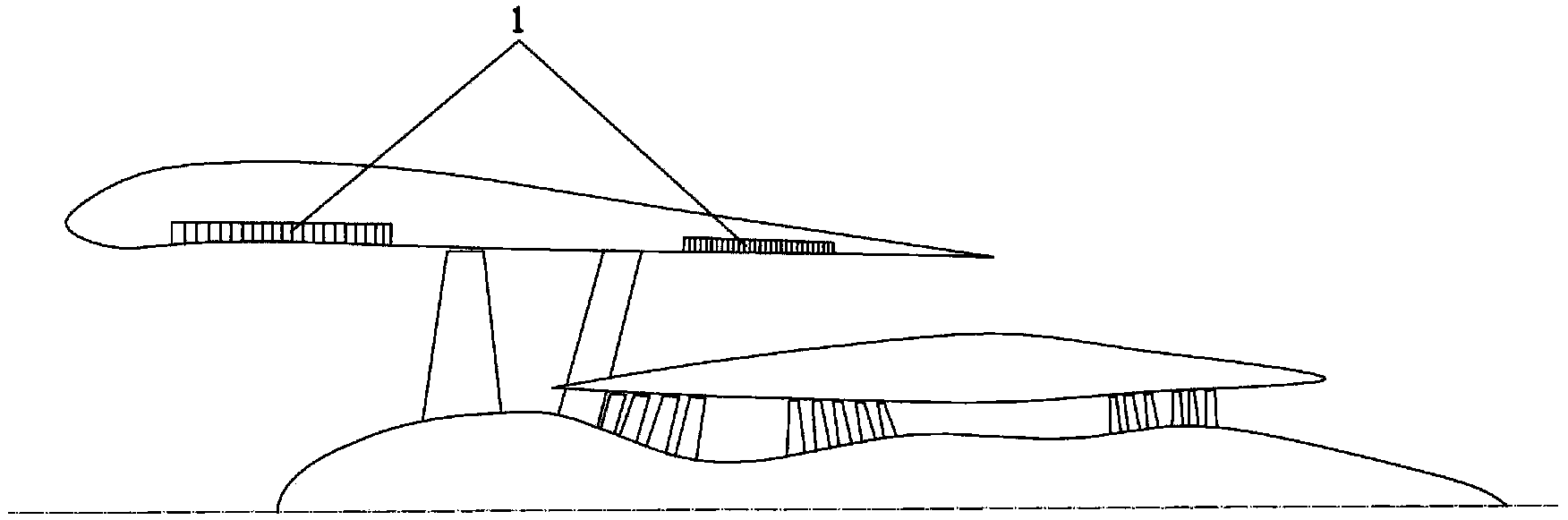

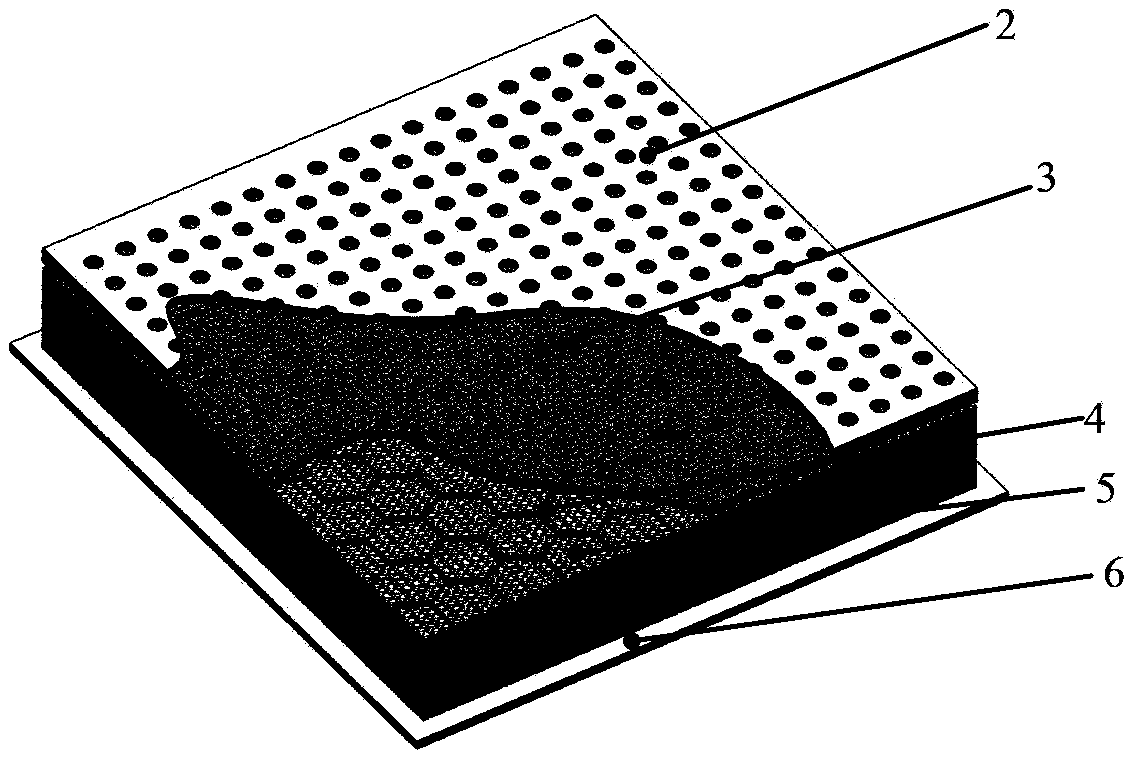

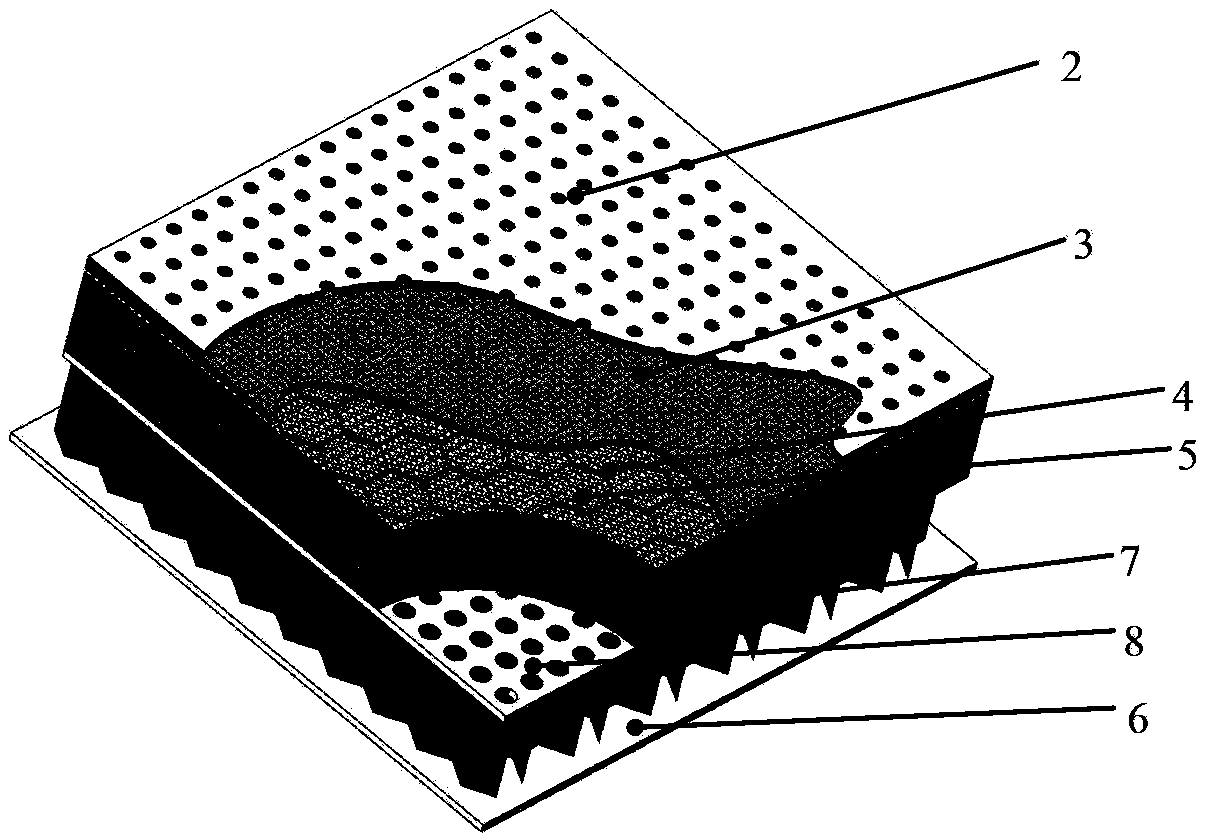

[0014] The invention provides a porous material acoustic lining which can be used for aero-engine noise reduction. The porous material is used as the inner core material of the aero-engine acoustic lining. The purpose is to use the porous material's excellent broadband sound absorption performance, high temperature resistance, and ultra-light The advantages of multi-function, combined with the perforated acoustic lining panel, constitute an excellent broadband sound-absorbing structure. In order to realize the above-mentioned acoustic lining structure, the present invention proposes the types of porous materials that can be applied to the interior of the aeroengine sound-absorbing acoustic lining, and provides several typical structural installation forms of the porous material acoustic lining.

[0015] figure 2 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com